2

2

2-127

2-127

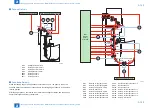

Technology > Pickup / Feed System > Pre-fixing feed Area > Pre-fixing feed assembly active lifter control

Technology > Pickup / Feed System > Pre-fixing feed Area > Pre-fixing feed assembly active lifter control

■

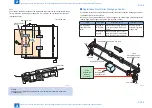

Pre-fixing feed assembly active lifter control

If the rigidity of the paper performed loop control is high, there is possibility that the impact

caused when the paper leading edge enters the fixing nip will spread to the secondary

transfer assembly and its upstream. And this will cause image failure (streak in the main

scanning direction).

In order to ease the impact when the paper enters the fixing nip, and avoid the impact to

spread to the upstream, this control moves the pre-fixing feed assembly up and down, and

switches the path.

The paper 227.3 mm or more with feed direction is controlled.

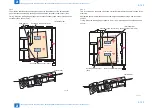

1. Change to the upper path

Timing: Before the paper leading edge passes the secondary transfer roller (in the specified

time after passing the PS59, the paper will be positioned in the post-secondary transfer

sensor (PS19)).

Standard sensor: Post-registration sensor (PS59).

Post-registration

sensor

PS59

F-2-178

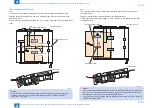

2. Change to the lower path

Timing: Before the paper leading edge arrives in the fixing roller.

Post-registration

sensor

PS59

F-2-179

Содержание imagePRESS 1110

Страница 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Страница 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Страница 733: ...7 7 Error Code Error Code Overview Location Code Pickup Position Code Pickup size Error Code Jam Code Alarm Code ...

Страница 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Страница 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...