2

2

2-120

2-120

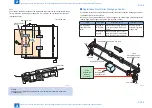

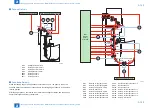

Technology > Pickup / Feed System > Active Registration Area Control / Function > Skew Correction Control

Technology > Pickup / Feed System > Active Registration Area Control / Function > Skew Correction Control

Step 5

The machine calculates the skew degree of paper by the difference of the time when the

paper reaches the secondary skew sensor (front) and the secondary skew sensor (rear).

Timing: When the leading edge of paper reaches the secondary skew sensor (front) and the

secondary skew sensor (rear).

<Overhead view>

<Lateral view>

Skew degree

Secondary skew sensor (rear)

Secondary skew sensor (front)

F-2-165

Step 6

This is to slow down the speed of the skew correction roller where the paper is ahead of the

other side.

Appropriate speed is estimated from the skew degree calculated at step 4 and is used for

control.

Timing: When the leading edge of paper is 0 mm – 40 mm ahead from the secondary skew

sensor.

<Overhead view>

<Lateral view>

slowdown

normal speed

Secondary skew sensor (rear)

Secondary skew sensor

(front)

skew correction roller (rear)

skew correction roller (front)

F-2-166

Содержание imagePRESS 1110

Страница 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Страница 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Страница 733: ...7 7 Error Code Error Code Overview Location Code Pickup Position Code Pickup size Error Code Jam Code Alarm Code ...

Страница 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Страница 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...