3D Systems, Inc.

93

p/n: 15-D100, rev. D

1

6.4 Every 3 Months

6.4.1 Replace Chiller Fluid

The chiller fluid needs to be replaced every 3 months to prevent

fluid evaporation which can cause a high concentration of

impurities.

1. Empty and clean the chiller tank.

2. Before filling the tank with new circulating fluid, the

customer must perform a quality check of the facility

water supply. The water should not be dirty or slimy, not

contain any foreign material and should comply with the

water quality standard shown in the table below or a 15%

aqueous solution of ethylene glycol. Use pH strips to check.

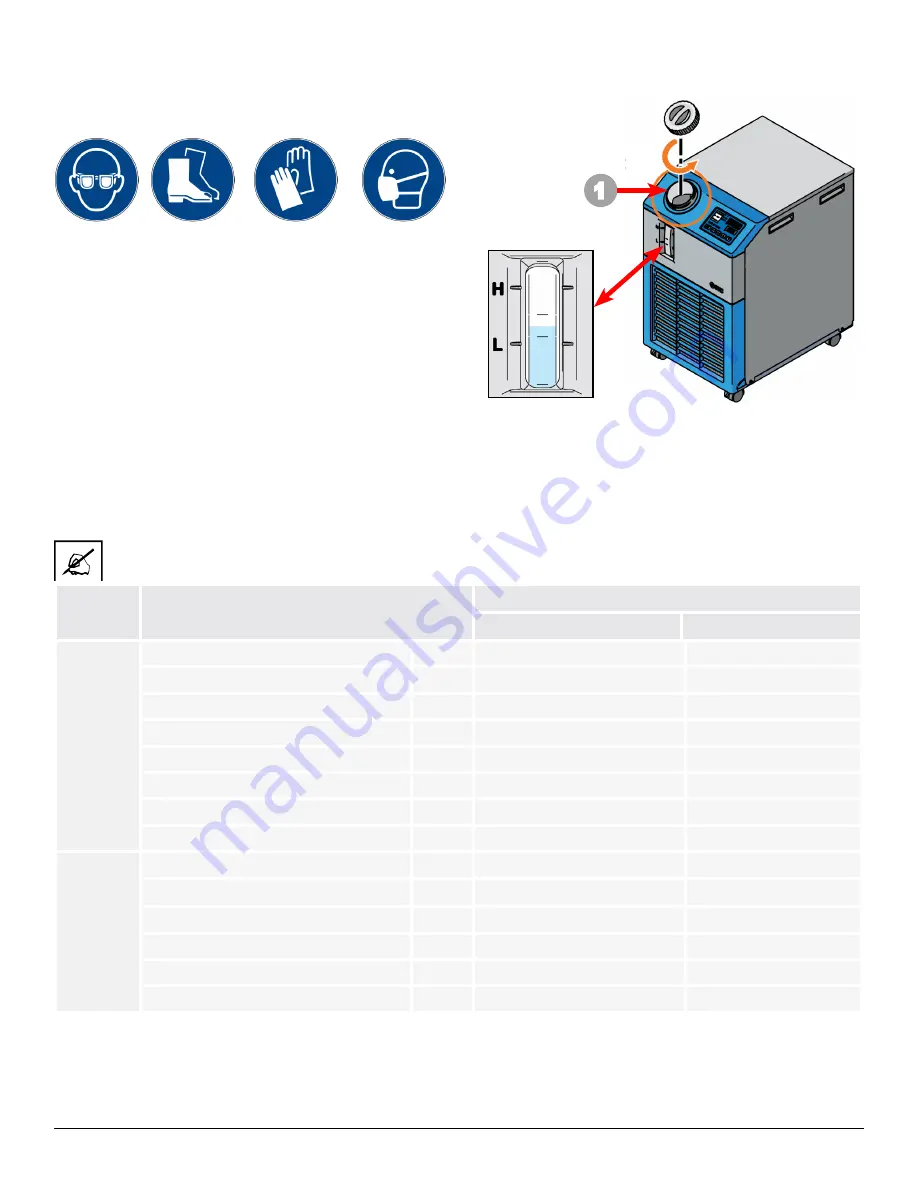

3. If the quality check is ok, turn the tank lid (1) counter-clockwise to open.

4. Add circulating fluid until the liquid level indicator reaches the “H” mark. The circulating fluid requires a mixture of tap water

and cooling fluid additives. Cooling fluid additives recommended by SMC are: Hexid A4, ControXid1642, Nalco CCL100, Cool

flow IGE, Dowcal 100 and opti. The correct mixture of tap water and cooling fluid additives must be according to

SMC guidelines (15%).

Note: The cooling fluid additives are to be supplied by the customer.

ITEM

STANDARD VALUE

CIRCULATING FLUID

FACILITY WATER

Standards

pH (at 25°C)

6.0 to 8.0

6.5 to 8.2

Electric conductance (at 25°C)

1 μS/cm and higher

100 to 800 μS/cm

Chloride ions

ppm

50 or less

200 or less

Sulfate ions

ppm

50 or less

200 or less

Acid consumption

ppm

50 or less

100 or less

Total hardness

ppm

70 or less

200 or less

Calcium hardness

ppm

50 or less

150 or less

Ionic silica

ppm

30 or less

50 or less

For

reference

Iron

ppm

0.3 or less

1.0 or less

Copper

ppm

0.1 or less

0.3 or less

Sulfide ions

ppm

Not detected

Not detected

Ammonium ions

ppm

0.1 or less

1.0 or less

Residual chlorine

ppm

0.3 or less

0.3 or less

Free carbon dioxide

ppm

4.0 or less

4.0 or less

6.4.2 Clean Machine Exterior

Vacuum the exterior DMP Flex 350 system using a wet-separator vacuum cleaner.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...