3D Systems, Inc.

73

p/n: 15-D100, rev. D

5.6 Remove Used Material

Caution: To reduce powder contact, it is strongly

recommended to close the printer door and

perform the following procedure through the

glove ports.

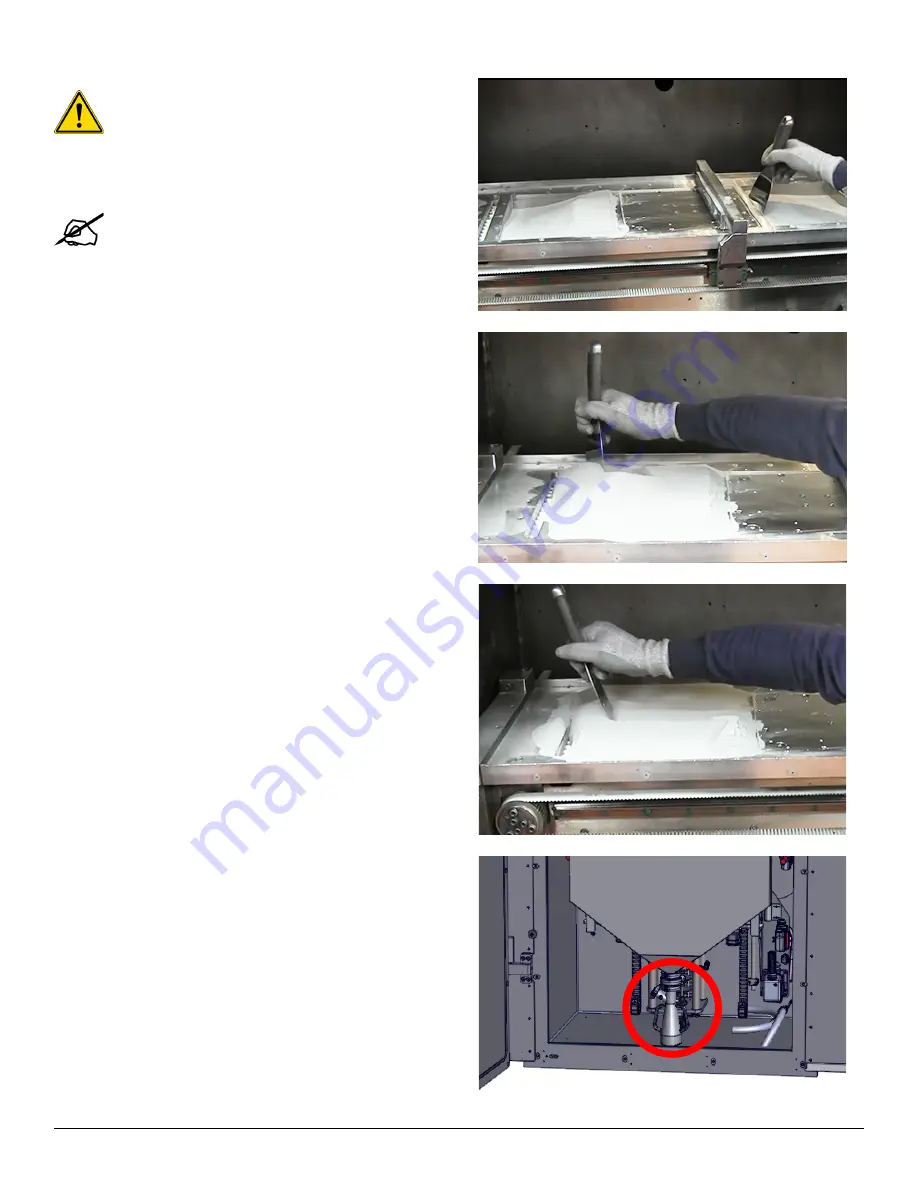

1. Using a stainless steel trowel level the material in the

material bins until they are leveled flat.

Note: This does not have to be exact. As long as

they are level to the eye, that is sufficient.

2. Use the control box inside the process chamber to bring

the material feeds up so the powder raises approximately

25 mm (25 000 µm)

above the print platform as shown in

the image to the right.

3. Push excess material into the overflow so it can be removed

from printer.

4. Continue purging material until the feed level is about

10000 µm

higher than the position marked in step 6 of the

previous paragraph. All powder underneath this level has

not yet been used and need not necessarily be purged and

sieved.

5. Repeat steps 1-3 for the opposite side.

6. To empty the overflow container, open the valve at the

bottom to transfer powder to the removable cartridge.

7. Close the valve when the cartridge is full. Remove the

cartridge. Repeat this procedure until the overflow

container is empty.

8. Use a sieving system to recycle usable material for the next

print job. Form more information on the recommended

sieving system, refer to the

DMP Sieving Station User

Guide (p/n: 15-D67)

available on InfoCenter.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...