3D Systems, Inc.

87

p/n: 15-D100, rev. D

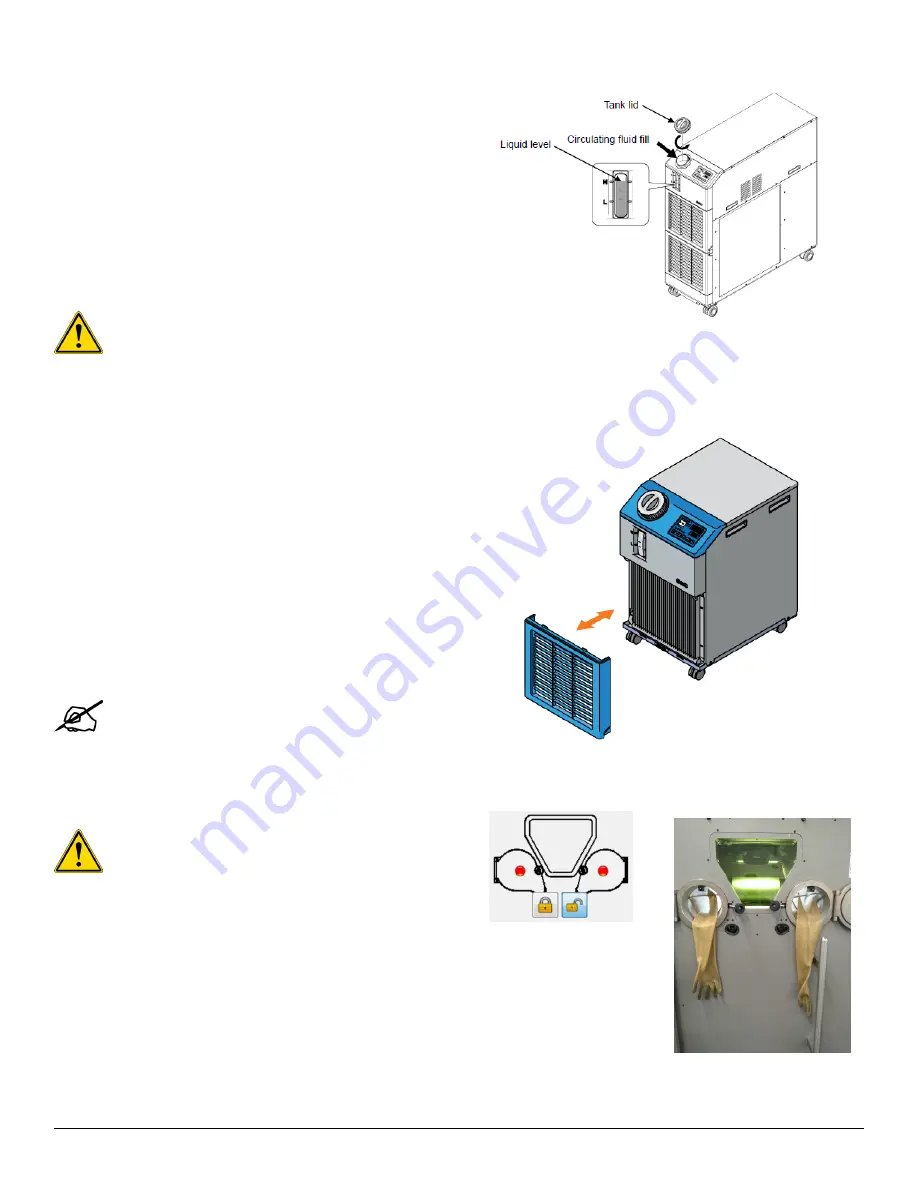

The chiller temperature can be read on the display. If the

temperature does not match the allowed tolerance (21-25°C),

please refer to the 3rd party information provided by SMC.

The water level of the chiller should never drop below the

minimum amount of fluid.

To refill the circulating fluid:

1. Turn the tank lid counter-clockwise to open.

2. Add circulating fluid until the liquid level indicator reaches

the “H” mark. Use tap water that complies with the water

quality standard shown in the table in §6.4.1 or a 15%

aqueous solution of ethylene glycol.

Caution: Make sure the facility water is not dirty,

slimy and no foreign matter is found.

6.3.3 Check Chiller Temperature and Water Level

6.3.4 Clean Vent Opening

If the fins of the air-condenser become clogged with dust or

debris, heat radiation performance reduces. This results in the

reduction of cooling performance, and may stop the operation

because the safety device is triggered.

Shut off the power supply of the product when performing

cleaning, maintenance or inspection to avoid electric shock,

injury or burn, etc.

Use a long bristled brush or air gun to clean the condenser to

prevent the fins from being deformed or damaged.

To replace the filter, remove the filter panel and replace

with Filter, Elements, Polyester Modacryclic, Dust Proof

(

p/n: 110388-00

).

Refer to the OEM documentation for detailed instructions.

Note: For any additional chiller maintenance

tasks, please refer to the 3rd party information

provided by SMC.

6.3.5 Check Printer Gloves

Caution: No powder must be in the process

chamber.

1. Close the printer door.

2. On the PC, open the

Set-up Mode

tab.

3. Click the

Unlock glove ports

button (dots should turn red)

and open the glove ports.

4. Roll out the gloves.

5. On the PC, click the

Test gloves

button. The process

chamber will create an overpressure of +25 mbar. This

pressure should be maintained during 5 minutes (+/- 3

mbar).

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...