3D Systems, Inc.

105

p/n: 15-D100, rev. D

E. Post Installation Procedure

20. Close the process chamber door and tighten the bolts.

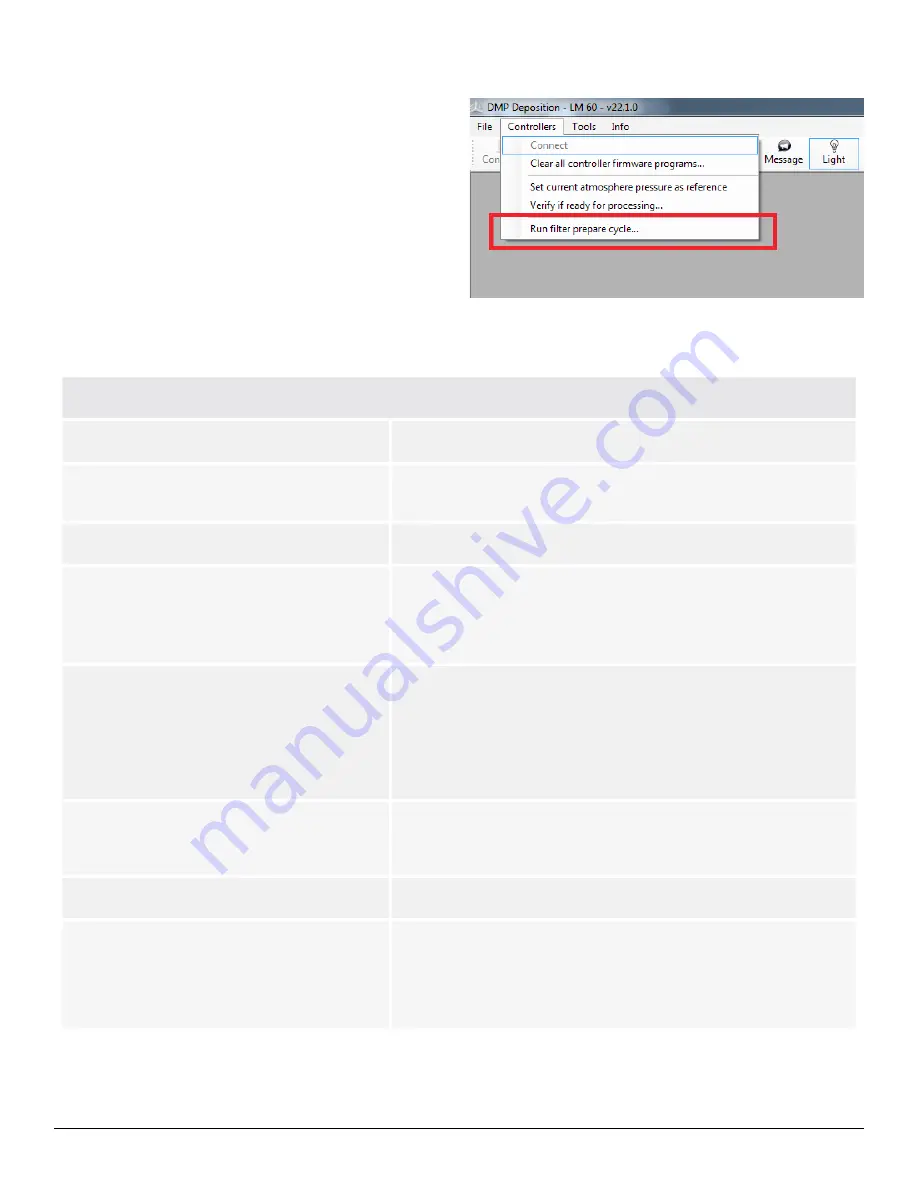

21. Go to DMP deposition.

22. In the top menu bar, select

Controllers > Run filter prepare

cycle

.

23. The filter will now be vacuumed and flushed with argon.

24. After the filter preparation cycle is complete, the printer is

ready to be used.

25. Check the KF50 clamps on the filter outlet valve and the

filter inlet valve. Tighten the KF50 clamps to 2 Nm (1.5 ft.

lbs.).

F.

Process filter FAQ

QUESTION

ANSWER

What is the filter element inside made of?

It is a polyester mesh.

Can we cut the cartridge open?

Absolutely NOT! The contents will react violently when exposed to

oxygen. The fume particles are pyrophoric in nature and will combust

when expose to air.

Can we crush the cartridge?

NO. The recommended method is incineration of the filter vessel intact.

Does the canister have to be immersed in

mineral oil before disposal?

The canister is fully certified (UN) as a container for the waste collected

in the filter. It can hence be shipped to a waste processing facility

without additional precautions not mentioned in the manual.

However, local legislation regarding the transport of dangerous goods

(ADR 9, ADR 4.2, ADR 4.3) may apply.

What is the contents of the used vessel?

The outer case is steel & stainless steel caps and Neoprene or viton

gaskets.

The inner filter element is polyester.

A stainless support scaffold.

The internal atmosphere is Argon.

The waste product is condensate produced from sintering metal

What is the chemical composition of the

condensate?

We do not have a precise chemical analysis, but the fume particles

produced in the process are not unlike those produced in welding

or plasma cutting operations of like materials (Titanium, Aluminum,

Stainless steel, etc).

Is the cartridge under pressure?

NO. It will be at atmospheric pressure when sealed and still be

blanketed in inert gas.

Is there a pressure relief valve?

There is no pressure release valve. When connected to a ProX DMP

/ DMP printer the pressure system of the printer will regulate the

pressure in the canister. The blind flanges installed on a full filter are

designed to withstand any pressure build-up expected during normal

conditions. In case of an external fire, the sealing clamps and internal

self-sealing valves are designed to fail so as not to create an explosion.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...