3D Systems, Inc.

2

p/n: 15-D100, rev. D

1.2.2 Oxygen Limits

The oxygen limit for running a job on a

DMP Flex 350

should be below 225ppm (ppm sensor limit) and 1.98% (% sensor limit).

The DMP Flex 350 system may reach 25ppm during the build process if running with proper consumables as per

DMP Flex 350

Facility Guide & User guide.

1.3 Copyright

©1993-2019. 3D Systems, Inc. All rights reserved. The content of this manual is furnished for informational use only, is subject

to change without notice, and should not be construed as a commitment by 3D Systems, Inc. Any names, places, and/or events

in this publication are not intended to correspond or relate in any way to individuals, groups or associations. Any similarity or

likeness of the names, places, and/or events in this publication to those of any individual, living or dead, place, event, or that of

any group or association is purely coincidental and unintentional.

1.4 Related Documentation

3D Systems documentation related to the DMP Flex 350 system can be found on

infocenter.3dsystems.com

IMPORTANT! All of these documents are updated regularly. Before operating the system, visit our

download the latest version. Information that is present in the accompanying documentation will generally

not be repeated in this document.

The following manuals are related to this system:

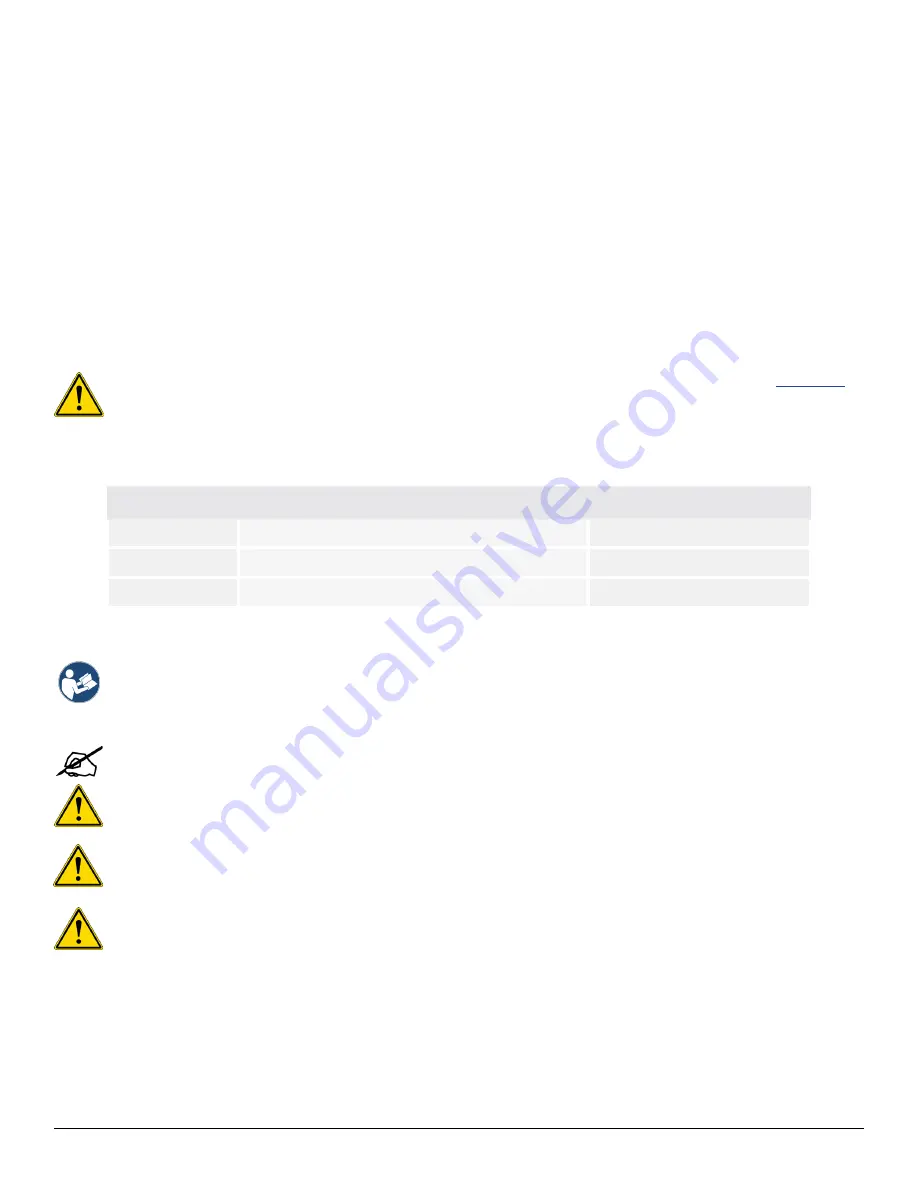

PART NR

TECHNICAL DOCUMENTATION

TARGET AUDIENCE

15-D99

DMP Flex 350 Facility Guide

Customer

15-D100

DMP Flex 350 User Guide

Customer

80-D0712

DMP Safety Guide

Customer

1.5 Safety Precautions

Read and perform all safety information in the DMP Safety Guide (p/n 80-D0712) and the specific safety

information in the user guides.

The following pictographs are used in this user guide:

A

Note

starts with the word ‘note’, the text is in bold black to emphasize a certain aspect that poses no hazard directly.

A

Caution

starts with the word caution, the text is in bold red to emphasize that as a certain aspect is not followed this

might lead to machine failure or potential hazard

A

WARNING

starts with the word warning, the text is in bold red to emphasize that as a certain aspect is not followed

the chance is high this leads to machine failure or potential hazard.

Caution: Once the DMP Factory 500 Printer Module is installed, it should not be moved without the aid of a

qualified, 3D Systems CSE. 3D Systems accepts no responsibility for damage to the modules by anyone other

than 3D Systems CSE.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...