3D Systems, Inc.

67

p/n: 15-D100, rev. D

7

5. The DMP Statistics window will pop up and provide

feedback on the previous job.

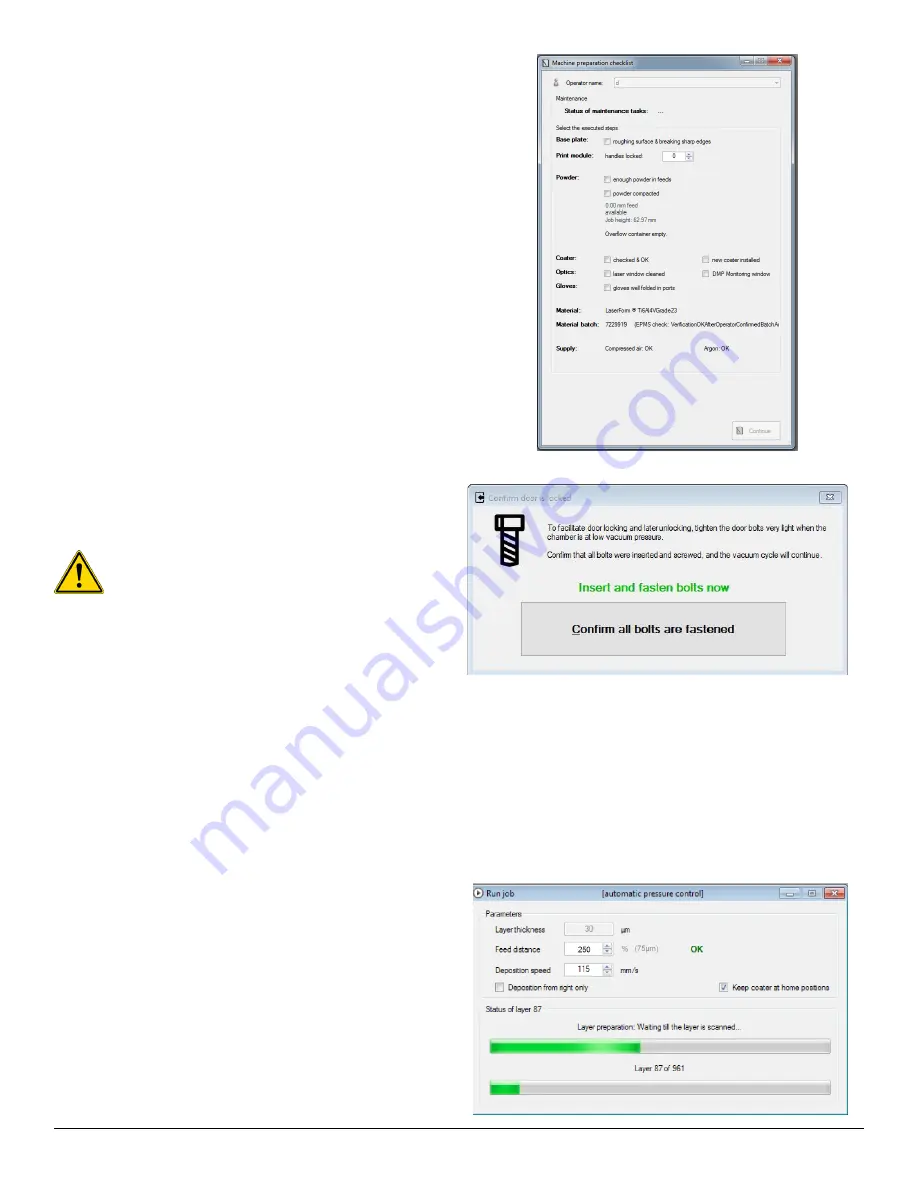

6. Next, the

Machine preparation checklist

will appear. Fill it in

appropriately to ensure the machine is prepared correctly.

7. Press

Continue

on the Machine preparation checklist. The

machine will now start removing the air from the process

chamber.

8. At -150 mbar the software will check for any leaks in the

system. At -800 mbar,

hand-tighten

each bolt on the

printer door to fully secure the printer door.

Caution: Do not over-tighten the printer door

bolts as it will be impossible to loosen them

afterwards when the printer chamber returns to

atmospheric pressure.

9. After the first preparation cycle a pop-up window will

appear. Click

Confirm all bolts are fastenend

.

10. The process chamber will go trough 3 inerting cycles. An

inerting cycle consists out of vacating the air out of the

process chamber and filling it with argon. This is performed

3 times to achieve oxygen levels of only 100 ppm.

When the 3 inerting cycles are finished, the DMP Flex 350 is

ready for printing.

11. During the automatic inertion cycle, the feeds will move

down and the powder in the feeds will become unflat. Use

manual operation to move the powder surface of the feeds

to just above the module top. Make sure you do not move

the build platform. Use the recoater to make a flat equal

powder bed.

12. In DMP Deposition, the

Run job

window is shown. In this

window, the feed can be changed during the job. At the

start of a job, the feed needs to be very high 300-350%.

The reason for this is that powder density at top of the feed

is not so high due to the vacuum preparation cycle: when

the machine is vacuuming the quick escape from air from

the powder creates loose powder at the top of the powder

feed platforms, the powder at the top is not compacted

as much as at the bottom of the feed. After 10 – 50 layers

you can start lowering the feed. A feed of approximately

250% (depending on the product volume) is recommended.

Higher volume parts need more powder, e.g. up to 320%.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...