3D Systems, Inc.

19

p/n: 15-D100, rev. D

WARNING: NEVER DISABLE OR OVERRIDE ANY SAFETY INTERLOCK DEVICE ON ANY DMP EQUIPMENT.

OPERATING EQUIPMENT WITH INTERLOCKS DEFEATED CAN CAUSE EQUIPMENT DAMAGE, INJURY, OR DEATH. IF

YOU SUSPECT A SAFETY INTERLOCK DEVICE IS NOT WORKING PROPERLY, DO NOT OPERATE YOUR DMP

EQUIPMENT. DISCONNECT POWER FROM THE EQUIPMENT AND CONTACT 3D SYSTEMS CUSTOMER SUPPORT FOR

ASSISTANCE.

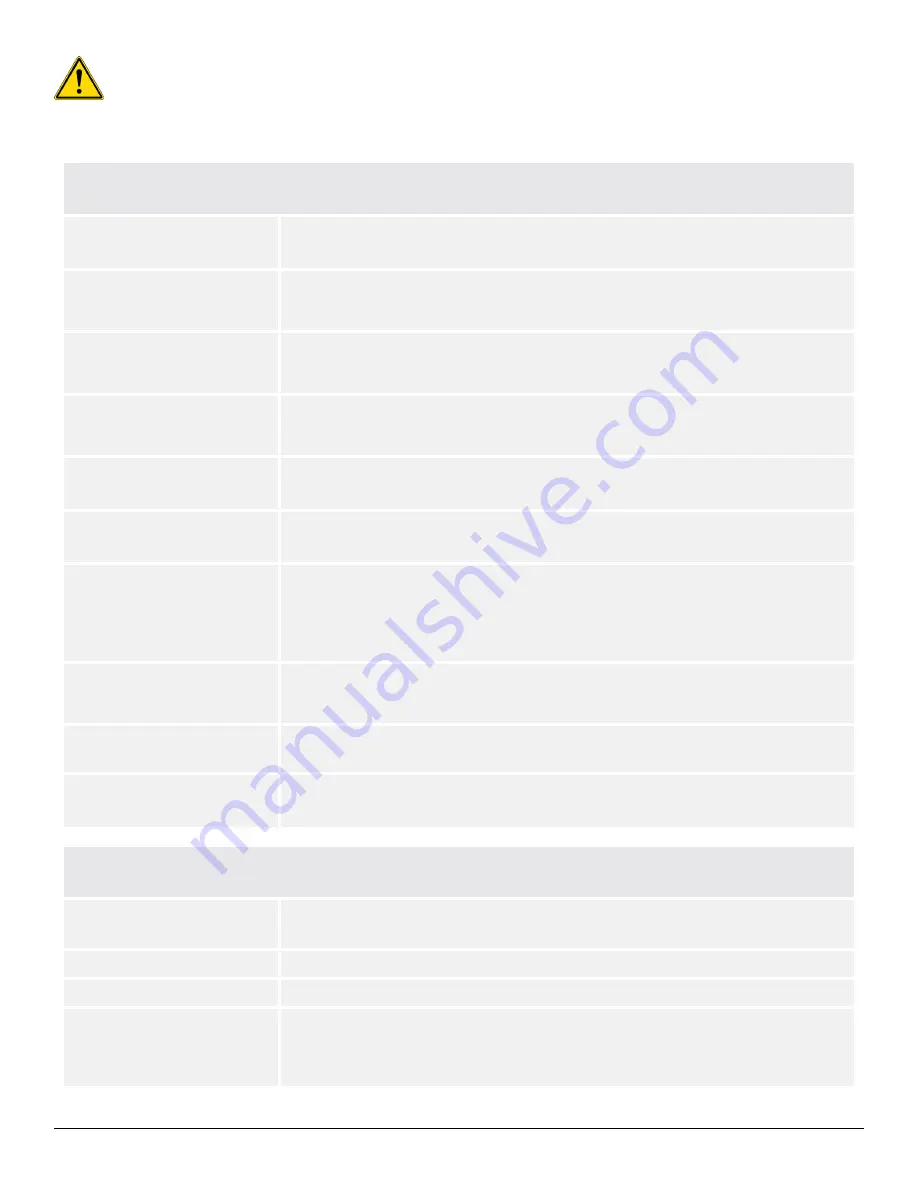

OVERVIEW OF THE SAFETY INTERLOCKS

Glove port sensors

Detects if the glove ports are open or closed. If open, the vacuum pump and blower

cannot start and no print job can be started.

Argon pressure sensors

Located in the pneumatic cabinet, the argon pressure sensor will detect if the pressure

of the compressed air goes out of range. If so, the system will go into alarm mode, a

warning message will appear on DMP Deposition and the print job will stop.

Compressed air pressure sensor Located in the pneumatic cabinet, the compressed air pressure sensor will detect if the

pressure of the compressed air goes out of range. If so, the system will go into alarm

mode, a warning message will appear on DMP Deposition and the print job will stop.

Relative pressure sensor

process chamber

Measures the relative pressure inside the process chamber. When out of spec, the sys-

tem will go into alarm mode, a warning message will appear on DMP Deposition and the

print job will stop. The argon and compressed air supply will be closed.

Oxygen (O

2

) pct sensor

Measures in the range in percentage (%) from zero (0) to 25 %. If the level of Oxygen (O

2

)

gas is over 2%, the laser will stop or not start.

Oxygen (O

2

) ppm sensor

Measures in the range in Parts Per Million (ppm) from zero (0) to 1000 ppm. If the level of

Oxygen (O

2

) gas is over 230 ppm, the laser stops or does not start.

Process door sensor

Detects the position of the door to the process chamber. If the door is open, the print

task will stop or not start.

Argon and compressed air supply will be closed.

Vacuum pump will be shut off.

Module blower, coater and laser will not work.

Liquid sensor

Detects whether liquid is present at the bottom plate of the laser compartiment.

If the liquid sensor detects liquid, the printer module will react the same as in case of an

emergency off.

Over-current circuit-breaker

If the over-current circuit-breaker detects an over-current the system will stop or not

start.

Main power switch

In the off position due to a lock-out / tag out procedure.

OVERVIEW OF THE SAFETY INTERLOCKS

Sensor on the doors of electrical

cabinet

Will trip main power switch if door is openen when By-pass is off.

Emergency off

See §: What happens in case of Emergency off

Slave OK

Both signals needs to be OK. If not, interconnection valves will remain closed.

Hold-to-run

If the process door is closed and the glove ports are open, the hold-to-run button inside

the process chamber will enable the coater.

If the process door is closed and the glove ports are closed and locked, the hold-to-run

button on the front control panel will move the coater.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...