3D Systems, Inc.

111

p/n: 15-D100, rev. D

7.5.3 Slicing and hatching a large, complex part takes longer than 2 days and crashes

A. Symptoms

File takes a very long time to process (more than two days) and crashes although your stl file is clean.

Crash isn’t at the same location every time.

B. Cause

The file is too complicated to do all the calculations.

This can happen when you have a lot of small holes in your part (more than 1000) or you have a very fine grid structure. The

number of contours that need to be calculated is enormous and takes a lot of time. These difficult calculations can cause a

crash.

C. Solutions

Split the geometry/stl file into different parts and process them separately. There are two possibilities to prevent voids in the

part, but you will always see the seams.

When you split the part it can be interesting to make the cuts in the middle and keep an outer contour part. The advantage of

this strategy is that the outer contour will be a single part without seams. But in the middle you are still stuck with the visible

section lines.

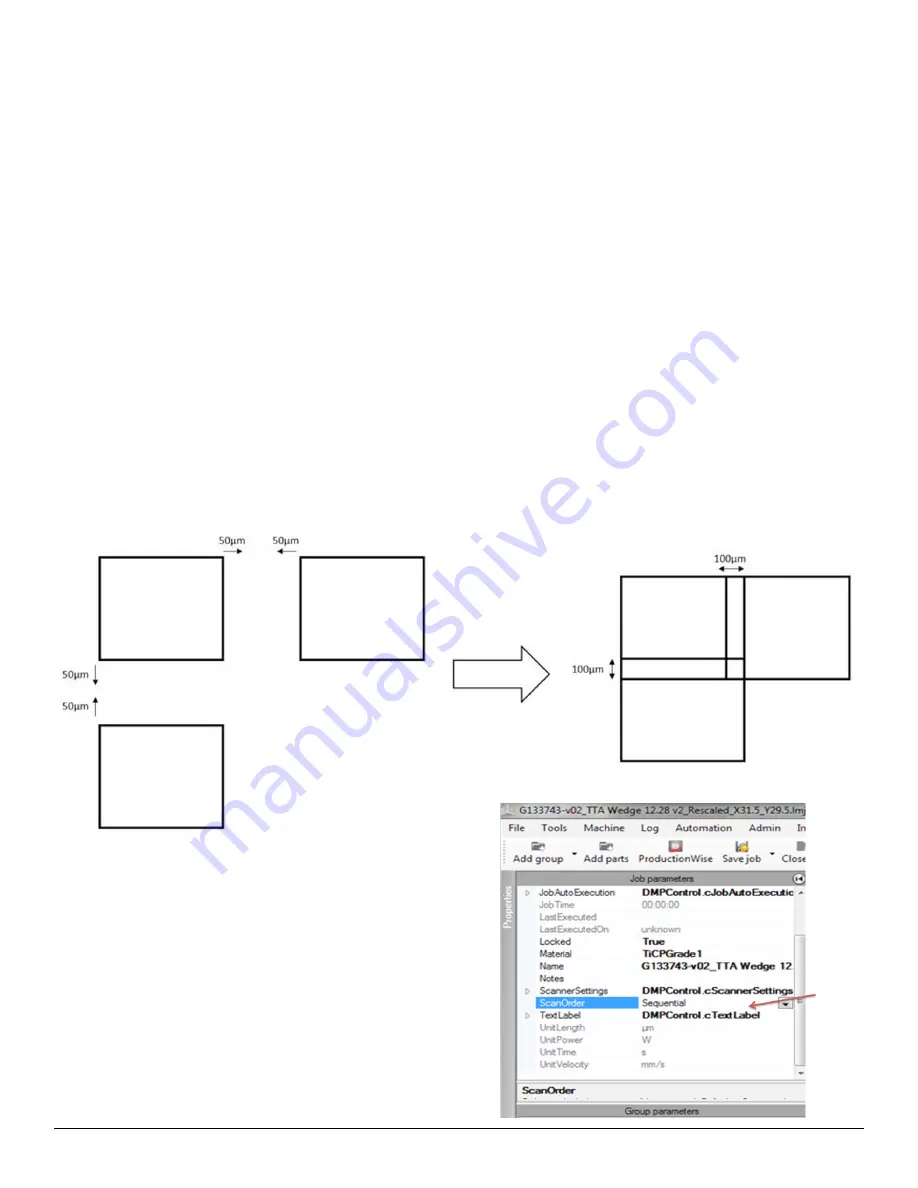

Option 1:

Provide a small overlap of a 100 micrometers between the sections. To do this you have to offset the surfaces that are next

to each other by 50 micrometers each as you can see in the figure below. Make certain to keep the sections at the original

positions so they are automatically positioned correctly in DMP Control afterwards.

Option 2:

Move the different parts slightly towards each other in DMP

Control so that outer contours are as close as a scan space

apart.

For both options it is advised to put the job ScanOrder to

“randomized” to have the best result. You can do this in DMP

Control:

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...