3D Systems, Inc.

75

p/n: 15-D100, rev. D

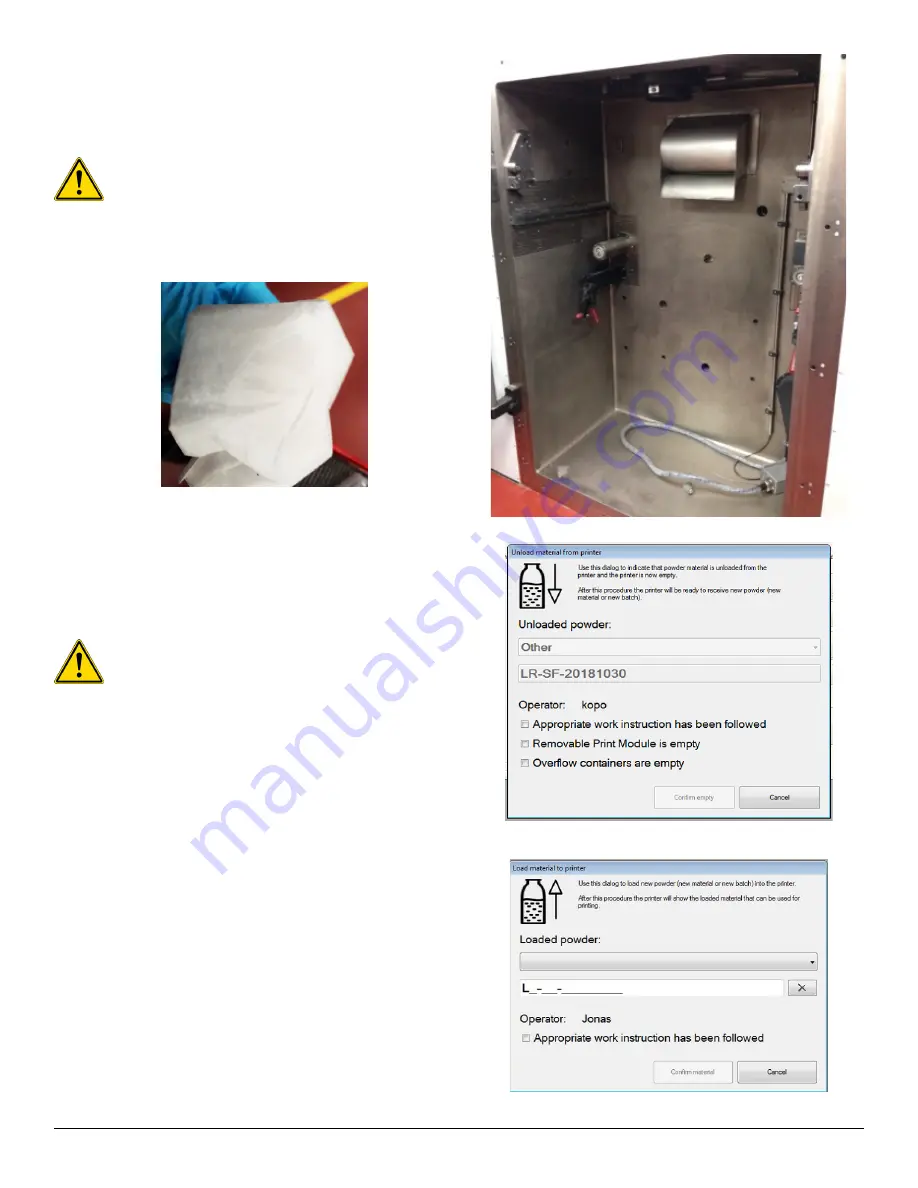

5. Vacuum the process chamber using a wet-separator

vacuum cleaner.

6. Additionally, clean the complete inside of the process

chamber using paper towels with isopropyl alcohol to

remove any remaining residue.

Caution: Pay special attention to the door viewing

window and the laser window as these are critical

components during the printing process. For more

detailed instructions on how to inspect and clean

the laser window, see § 6.2.2

7. In DMP Deposition, click

Material

>

Unload material

to open

the

Unload material from printer

pop-up window. Check

all boxes that have been completed and click

Confirm

empty

. The systems is now empty and ready to receive new

powder/batch/material.

Caution: This action needs to be performed before

a new batch or new material can be loaded

8. Install the printer module with new material.

9. Home the axis of the new printer module.

10. In DMP Deposition, click

Material

>

Load material

to open

the

Load material

pop-up window

11. Begin your next build.

12. Place a cover over the powder feeds of the printer module

that is removed from the process chamber to protect the

material from dust and any other contaminents.

13. If a printer module is to remain unused for an extended

period of time (1 week+), remove all the material from this

printer module as described the previous procedure. Store

the material as described in the section

“Material Safety”

,

in the

DMP Safety Guide (p/n: 80-D0712)

.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...