3D Systems, Inc.

96

p/n: 15-D100, rev. D

B. Procedure

Caution: To make sure the process filter is

replaced in the safest conditions possible, 3D

Systems highly recommends to roll out the

process filter cart to a safe and secure location

before removing the process filter inlet and outlet

valves. This will minimize the risk involved should

oxygen enter the process filter when removing

the valves.

1. Before beginning this procedure, make certain no print job

is running and the system is idle.

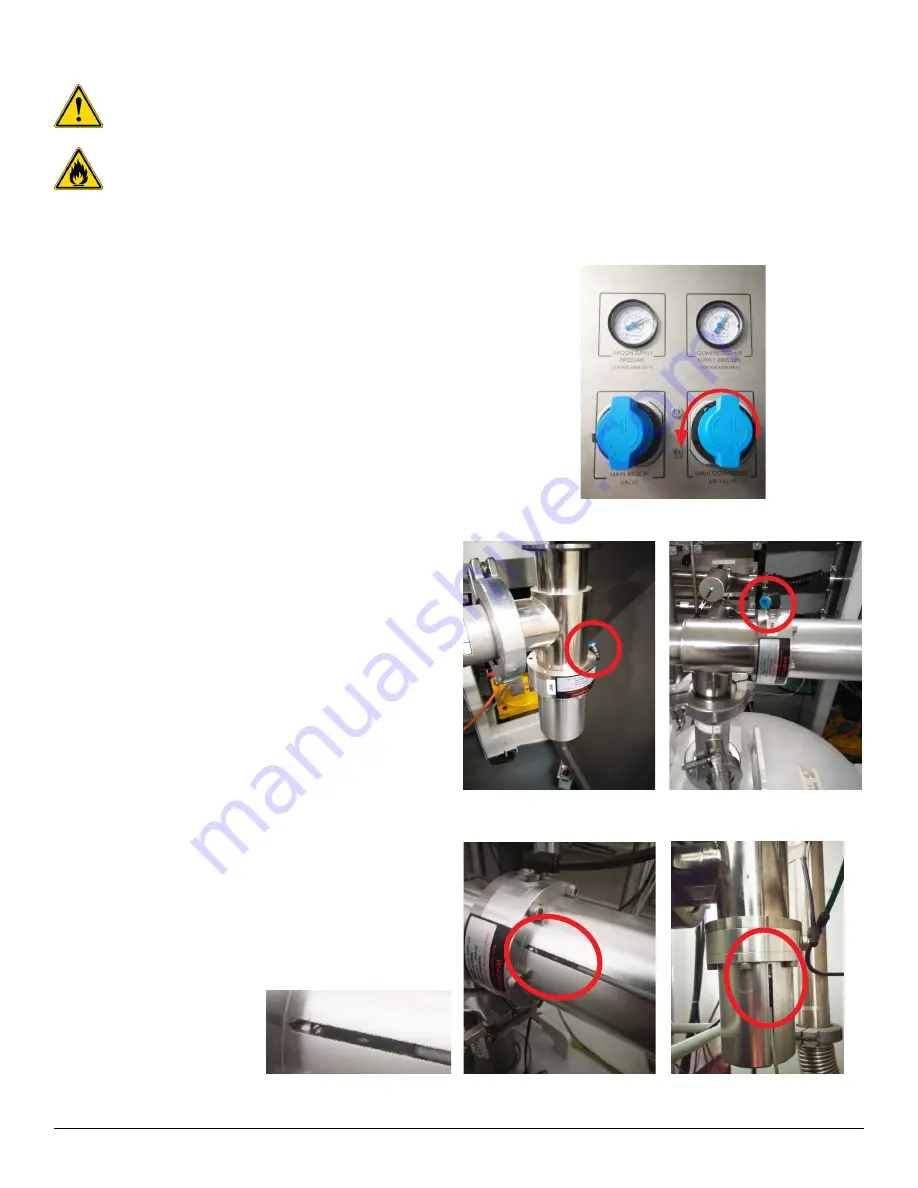

2. On the rear control panel of the printer, turn the main

compressed air valve counterclockwise. This will close the

facility supply of compressed air and bleed any remaining

compressed air pressure in the system.

3. Disconnect the compressed air tubes from the push-

fit connections

PNV2

&

PNV3

. The process filter valves

are only opened by compressed air. Disconnecting the

compressed air supply will guarantee the valves remain

closed and no oxygen can enter the process filter.

4. Use a small flathead screwdriver to loosen and slide out 2

inductive valve sensors, 1 on each valve.

Содержание DMP Flex 350

Страница 1: ...DMP Flex 350 Production printer User guide Original instructions ...

Страница 11: ...3D Systems Inc 6 p n 15 D100 rev D 1 x on the printer door 1 x on the scanner 2 1 4 Laser Safety Label ...

Страница 119: ...3D Systems Inc 114 p n 15 D100 rev D 8 BASIC REGULATIONS 8 1 EC Declaration of Conformity DoC ...