7

MMC-329 Rev.E 5/08

ZF Marine Electronics, LLC

Mukilteo Plant

This Service Sheet reflects all current variations of the standard 3-detent ZF Marine Electronics MC2000 Series Control

Heads

REQUIREMENTS

:

MicroCommander/ClearCommand: one (1) 8-Conductor Cable per Control Head lever.

Pluggable MicroCommander/ClearCommand: one (1) Control Head Harness per Control Head lever.

CruiseCommand: one (1) Control Head Harness per Control Head lever.

Included with the Control Head:

• Mounting screws

• Terminals (For 8-Conductor or 1-Connector Harnesses)

• Watertight cable grip for the cable entrance on the Processor (For 8-Conductor)

When the Control Head is properly mounted on a console, it is spray proof from the top only. An adhesive gasket is

mounted on the bottom of the Control Head to seal it to the mounting surface. However, below the mounting

surface it needs protection from water or spray. Consider using a Weather Mount Enclosure, which is available from

ZF Marine Electronics.

MOUNTING AND INSTALLATION:

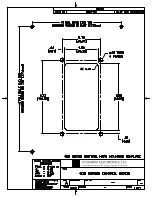

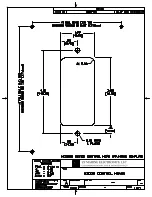

A) Select the desired mounting locations and make cutouts per template. Refer to the Dimensions Diagram.

B) Check that the two mounting screws will start into the Control Head. Remove Control Head from cutout.

C) Run cable/harnesses between Processor and Control Head. Label both ends with the Station ID. (EXAMPLE:

Port, Center, or Starboard; Port Thrust, Port Throttle; etc.)

There are two types of Control Head connections available: Plug or Terminal Connected. Both types may be used with

MicroCommander, ClearCommand, or CruiseCommand using the appropriate cable or harness. Follow the appropriate

steps for the Control Head that has been supplied for your system.

Pluggable

A) Plug Control Head cable into the pigtail at the Control Head. (Ensure the correct Processor Cable is being plugged into

the corresponding Control Head lever pigtail).

B) When connecting the plugs, ensure that the release button or buttons are depressed and held until plug is fully

connected or disconnected.

C) Connecting or disconnecting plugs without depressing and holding the release button or buttons will damage the plug.

MC2000 Series Standard Control Head Variations

Part Numbering Configurations

Detents Available

Dimensions

Summary of Contents for ClearCommand 9000 Series

Page 132: ......

Page 133: ...APPENDIX A...

Page 134: ......

Page 139: ......

Page 140: ...Page A 4...

Page 143: ......

Page 144: ...10...

Page 148: ...Page A 18...

Page 149: ...Page A 19 TEMPLATE...

Page 150: ...Page A 20...

Page 152: ...Page A 22...

Page 154: ...Page A 24...

Page 156: ...Page A 26...

Page 157: ...Page A 27 Drawing 11488D 1 Twin Screw Single APS Connection Alternate Remote Switch...

Page 158: ...Page A 28...

Page 159: ...Page A 29 Drawing 11488D 2 Twin Screw Dual APS Connections...

Page 160: ...Page A 30...

Page 161: ...Page A 31 Drawing 11488D 3 APS Notes Page...

Page 162: ...Page A 32...

Page 164: ...Page A 34...

Page 166: ...Page A 36...

Page 170: ...Page A 40...

Page 172: ...Page A 42...

Page 176: ...Page A 46...

Page 178: ...Page C 48 ZF Mathers LLC 12125 Harbour Reach Drive Suite B Mukilteo WA 98275...

Page 179: ...APPENDIX B...

Page 180: ......

Page 234: ...Appendix B 6...

Page 238: ...Appendix B 10...

Page 242: ...Appendix B 14...

Page 247: ...Service Field Test Unit Reference Manual MM13927 Rev E 4 07...

Page 248: ......

Page 250: ...Page ii Table of Contents...

Page 264: ...SERVICE FIELD TEST UNIT MM13927 RvD 10 03 Page 3 2...

Page 265: ...APPENDIX C...

Page 266: ......

Page 267: ...Appendix C 1 Drawing 12284A 1 ClearCommand Diagram all options...

Page 268: ...Appendix C 2...

Page 269: ...Appendix C 3 Drawing 12284A 2 ClearCommand Circuit Board Connections...

Page 270: ...Appendix C 4...

Page 271: ...Appendix C 5 Drawing 12284A 3 ClearCommand Drawing Notes Page...

Page 272: ...Appendix C 6...