7

0

4-3-1 Check / Adjustment of needle bar change unit

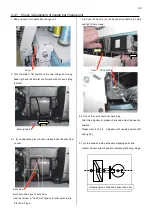

3-1. For adjustment the sensor and slit position, pleaseloose

a screw on the slit.

< Note >

Please do NOT loose LEFT side screw.

Set screw

3-2. Please adjust slit position to center of slit gap against

sensor when needle selection cam is middle position on

flat.Then tight screw of slit.

3-3. Turn the knob and confirm position of sensor and slit.

When needle selection cam is position on flat, angle of slit

against sensor should be even like below drawing.

4. Turn the knob and move moving head to 15

th

needle.

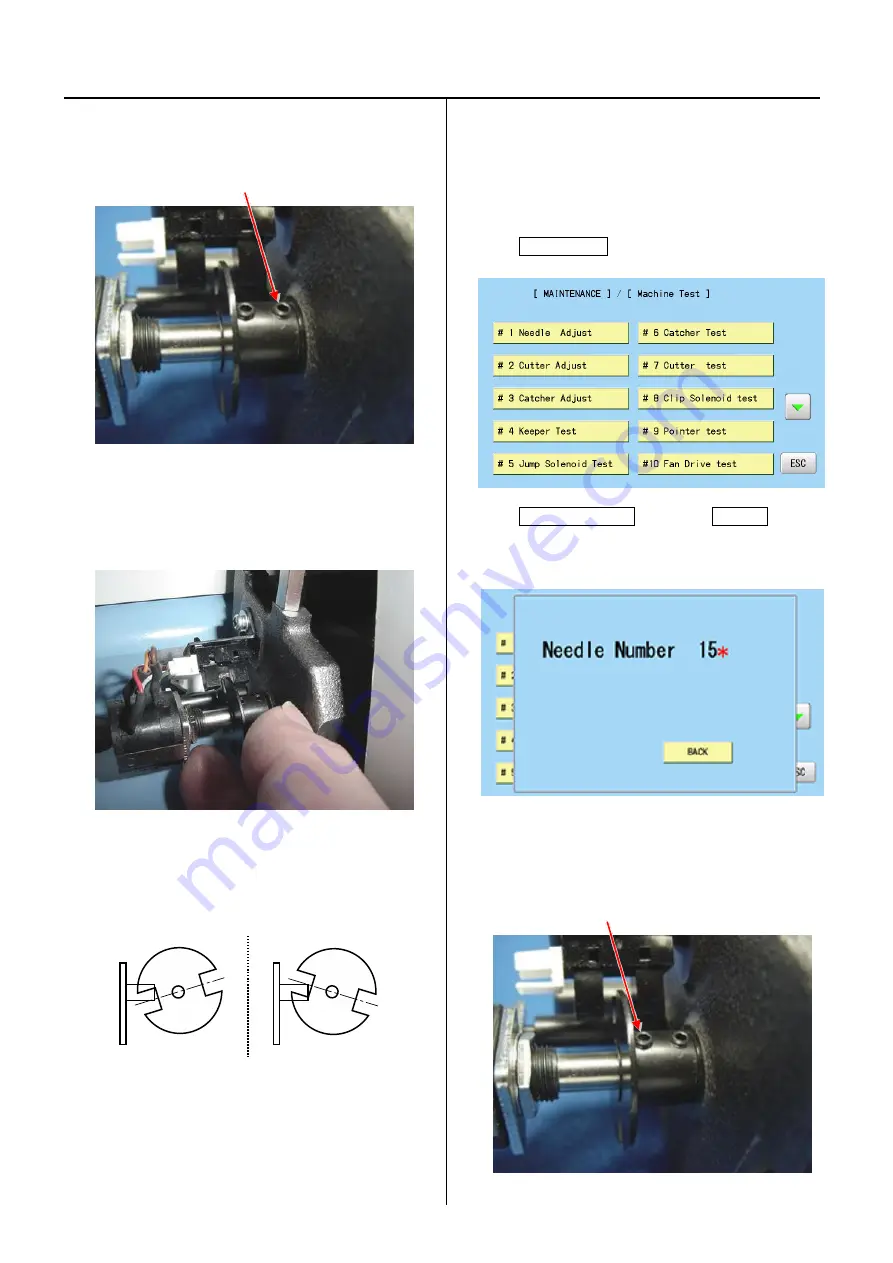

5. Enter maintenance mode, referring to [ E5-1 How to enter

maintenance mode ]

6. Press

Machine Test

.

7. Press

#1 Needle Adjust

and press

Position

.

Should showing [Needle Number 15* ] and has beep

sound.

7-1. If your machine showing different (wrong needle number

or non * mark) message, potentiometer position is not

correct. Please loose left side screw of slit.

< Note >

Please do NOT loose right side screw.

Set screw

Summary of Contents for HCR3-1502

Page 1: ... Maintenance Manual for Embroidery Machine HCR3E SERIES Version 1 2 HappyJapan Inc ...

Page 104: ...105 4 7 3 Adjustment of timing detecting unit 8 Finally put the cover back on ...

Page 107: ...107 ...

Page 172: ...172 E7 Electric system diagram E7 1 Pulse motor driver PMD wiring ...

Page 173: ...173 E7 2 Pulse motor driver PMD setup ...

Page 174: ...174 E7 3 Inverter wiring ...

Page 175: ...175 E7 4 Electrical connection diagram ...

Page 176: ...176 ...

Page 177: ...177 ...

Page 178: ...178 E7 5 List of electrical connection diagram ...

Page 179: ...179 ...

Page 180: ...180 E7 6 Explanation of function clrcuit board HCD8122 LCD CE MX Board Ass y ...

Page 181: ...181 HCD8116 TP SW Circuit Board Ass y CN No Function CN1 Switch output LED input ...