69

4-3-1 Check / Adjustment of

needle bar change unit

1. Remove cover for needle bar change unit.

Cover

2. Turn the knob to flat position of the cam and push moving

head right and left side for confirm should not have a play

the Cam.

Moving head

2-1. If you had feel a play the cam, please loose the set screw

on cam.

Set screw

Both hole has 2 pcs of set screw.

Inner set screw is "Cup Point" type and outer set screw is

"Flat Point" type.

2-2. Push the Cam to

right

and push drive shaft to

left

side

and tight Cam screws.

Cam Drive shaft

2-3. Check the cam should not have play.

After this adjustment, please check and adjust the needle

position.

Please refer to [ 4-2-4 Adjustment of needle position (left

and right) ].

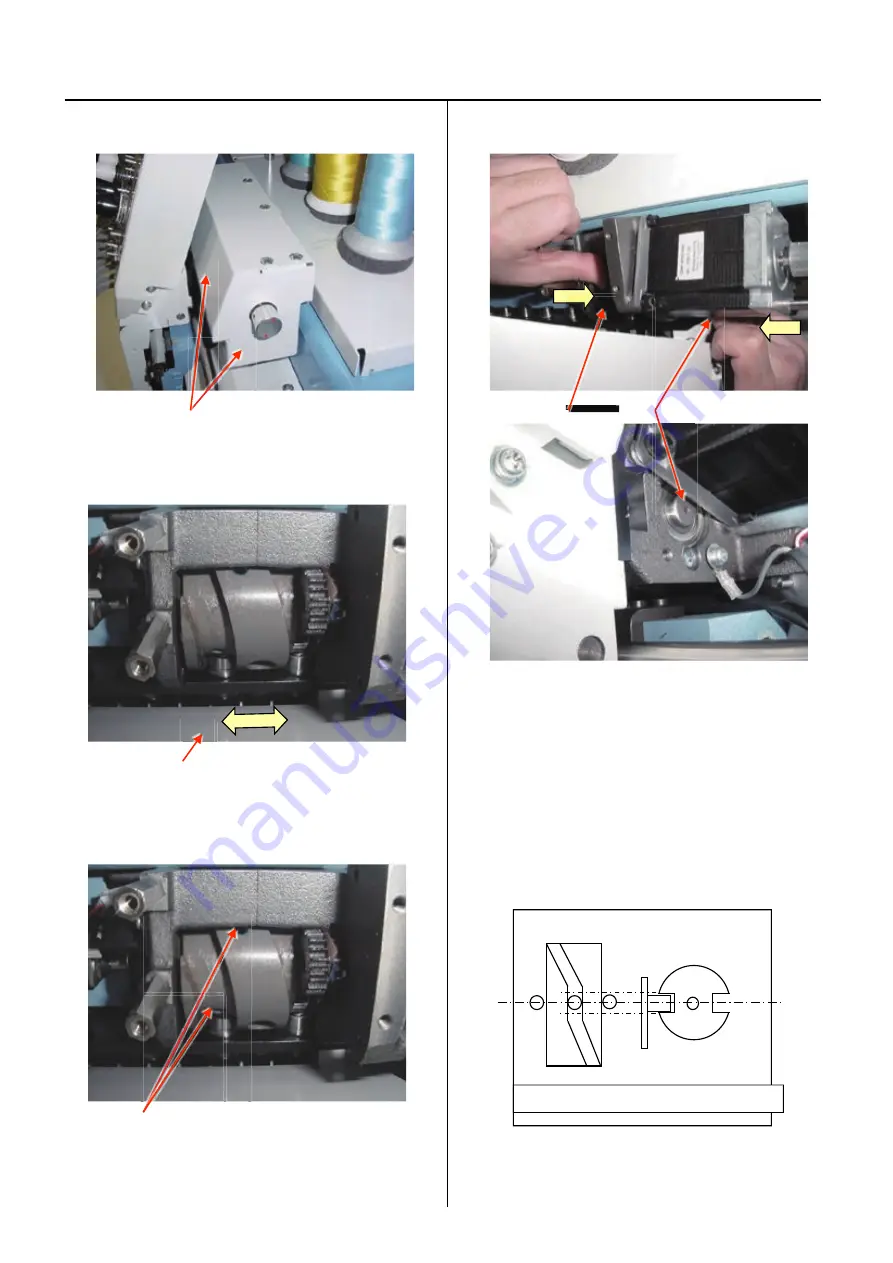

3. Turn the knob and stop at needle stopping point and

confirm Senser and slit position reference following image.

Imagine figure of position sensor and cam

Summary of Contents for HCR3-1502

Page 1: ... Maintenance Manual for Embroidery Machine HCR3E SERIES Version 1 2 HappyJapan Inc ...

Page 104: ...105 4 7 3 Adjustment of timing detecting unit 8 Finally put the cover back on ...

Page 107: ...107 ...

Page 172: ...172 E7 Electric system diagram E7 1 Pulse motor driver PMD wiring ...

Page 173: ...173 E7 2 Pulse motor driver PMD setup ...

Page 174: ...174 E7 3 Inverter wiring ...

Page 175: ...175 E7 4 Electrical connection diagram ...

Page 176: ...176 ...

Page 177: ...177 ...

Page 178: ...178 E7 5 List of electrical connection diagram ...

Page 179: ...179 ...

Page 180: ...180 E7 6 Explanation of function clrcuit board HCD8122 LCD CE MX Board Ass y ...

Page 181: ...181 HCD8116 TP SW Circuit Board Ass y CN No Function CN1 Switch output LED input ...