3.2.4 Diagnosis

DANGER!

The diagnosis data is not safety-relevant and, thus, shall not be used in safety application program for

execution of safety functions.

during the start-up of Safety I/O modules.

AI581-S

UP 24VDC 2W

4SAI

Safety Analog Input

3.8 UP

3.9 ZP

3.4

3.7

3.0 I2-

3.1 FE

3.2 I3-

3.3 FE

3.5

3.6

ERR1

2.9ZP

2.8UP

2.3

2.4

2.5

2.1

2.7

2.6

2.2I1+

2.0I0+

ERR2

4.9ZP

4.8UP

4.7

4.2I3+

4.0I2+

4.6

4.5

4.4

4.3

4.1

PWR

1.9ZP

1.8UP

1.7

1.4

1.0I0-

1.2I1-

1.3FE

1.1FE

1.5

1.6

ADDR

x10H

ADDR

x01H

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

AI581-S

UP 24VDC 2W

4SAI

Safety Analog Input

3.8 UP

3.9 ZP

3.4

3.7

3.0 I2-

3.1 FE

3.2 I3-

3.3 FE

3.5

3.6

ERR1

2.9ZP

2.8UP

2.3

2.4

2.5

2.1

2.7

2.6

2.2I1+

2.0I0+

ERR2

4.9ZP

4.8UP

4.7

4.2I3+

4.0I2+

4.6

4.5

4.4

4.3

4.1

PWR

1.9ZP

1.8UP

1.7

1.4

1.0I0-

1.2I1-

1.3FE

1.1FE

1.5

1.6

ADDR

x10H

ADDR

x01H

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

AI581-S

UP 24VDC 2W

4SAI

Safety Analog Input

3.8 UP

3.9 ZP

3.4

3.7

3.0 I2-

3.1 FE

3.2 I3-

3.3 FE

3.5

3.6

ERR1

2.9ZP

2.8UP

2.3

2.4

2.5

2.1

2.7

2.6

2.2I1+

2.0I0+

ERR2

4.9ZP

4.8UP

4.7

4.2I3+

4.0I2+

4.6

4.5

4.4

4.3

4.1

PWR

1.9ZP

1.8UP

1.7

1.4

1.0I0-

1.2I1-

1.3FE

1.1FE

1.5

1.6

ADDR

x10H

ADDR

x01H

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

AI581-S

UP 24VDC 2W

4SAI

Safety Analog Input

3.8 UP

3.9 ZP

3.4

3.7

3.0 I2-

3.1 FE

3.2 I3-

3.3 FE

3.5

3.6

ERR1

2.9ZP

2.8UP

2.3

2.4

2.5

2.1

2.7

2.6

2.2I1+

2.0I0+

ERR2

4.9ZP

4.8UP

4.7

4.2I3+

4.0I2+

4.6

4.5

4.4

4.3

4.1

PWR

1.9ZP

1.8UP

1.7

1.4

1.0I0-

1.2I1-

1.3FE

1.1FE

1.5

1.6

ADDR

x10H

ADDR

x01H

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

C

4

3

B

2

A

1

9

0

8

F

7

E

6

D

5

1

2

4

3

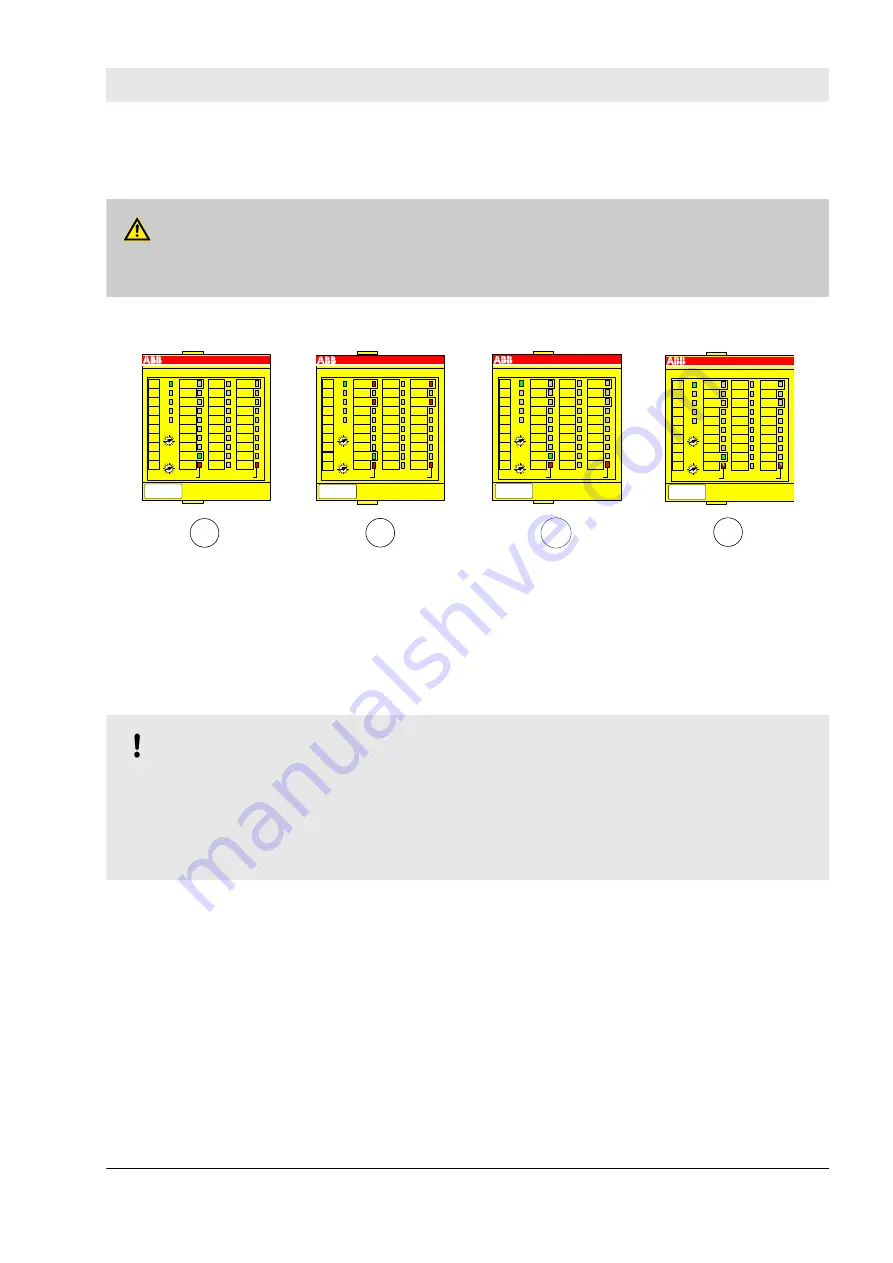

Fig. 15: LED states of Safety I/O modules during start-up (example with AI581-S module)

1

State 1 – Hardware reset and initialisation

2

State 2 – LED test

3

State 3 – End state of initialization

4

State 4 – Parameterisation is complete, but no

PROFIsafe communication yet

NOTICE!

External errors (wiring or sensor errors) in Safety I/O modules lead to the channel passivation (“0”

values are delivered). As soon as an external error is fixed and this is recognized by internal Safety

I/O module tests, Safety I/O module channels request an acknowledgement for their reintegration to

the normal safety process control mode. The user can acknowledge such channels using dedicated

channel bits (

Chapter 4.3.5 “Instantiation and configuration of safety modules/Definition of variable

Safety I/O module error messages are aggregated together with other module error messages in PM5xx

CPU. The following two tables include a list of error messages related to Safety I/O modules.

AC500-S Safety Modules

Generic Safety I/O module behaviour > Diagnosis

30.03.2017

AC500-S

71