Protective Elements

Commissioning: Overcurrent Protection, directional [67]

Object to be tested

For each directional overcurrent element is to be measured: the total tripping time (recommendation) or alternatively

tripping delays and the fallback ratios; each time 3 x single-phase and 1 x three-phase.

Especially in Holmgreen connections, wiring errors can happen easily and

these are then detected safely. By measuring the total tripping time, it can be

ensured that the secondary wiring is o.k. (from the terminal on, up to the trip

coil of the CB ).

It is recommended to measure the total tripping time instead of the tripping

time. The tripping delay should be specified by the customer. The total tripping

time is measured at the position signaling contacts of the CBs (not at the relay

output!).

Total tripping time: = tripping delay (please refer to the tolerances of the

protection stages) + CB operating time (about 50 ms)

Please take the CB switching times from the technical data, specified in the

relevant documentation, provided by the CB manufacturer.

Necessary means

Synchronizable current and voltage sources

May be: ampere meters

Timer

Procedure

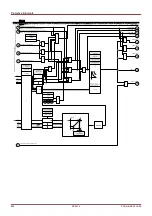

Synchronize the 3-phase current and voltage sources with each other. Then simulate the tripping directions to be

tested by the angle between current and voltage.

Testing the threshold values

(3 x single-phase and 1 x three-phase)

Each time feed a current which is about 3-5% above the threshold value for activation/tripping. Check then the

threshold values.

Testing the total tripping delay

(recommendation)

Measure the total tripping times at the auxiliary contacts of the CB (CB tripping).

Testing the trip delay

(measured at the relay output)

Measure the tripping times at the relay output.

Testing the fallback ratio

Reduce the current to

97%

below the trip value and check the fallback ratio.

Successful test result

The measured total tripping delays or individual tripping delays, threshold values and fallback ratios correspond with

those values, specified in the adjustment list. Permissible deviations/tolerances can be found under Technical Data.

703

MCDLV4

DOK-HB-MCDLV4-2E

Содержание HighPROtec MCDLV4

Страница 1: ...Manual Line Differential Protection MCDLV4 Software Version 3 4 a DOK HB MCDLV4 2E Revision A English...

Страница 3: ...Order Code Order Code 3 MCDLV4 DOK HB MCDLV4 2E...

Страница 47: ...Installation and Connection 47 MCDLV4 DOK HB MCDLV4 2E...

Страница 164: ...Input Output and LED Settings 164 MCDLV4 DOK HB MCDLV4 2E...

Страница 433: ...Parameters 433 MCDLV4 DOK HB MCDLV4 2E...

Страница 457: ...Device Parameters 457 MCDLV4 DOK HB MCDLV4 2E...

Страница 473: ...Blockings 473 MCDLV4 DOK HB MCDLV4 2E...

Страница 822: ...Protective Elements Name Description Profibus Scada Cmd 16 Scada Command 822 MCDLV4 DOK HB MCDLV4 2E...

Страница 988: ...Protective Elements 988 MCDLV4 DOK HB MCDLV4 2E P P Q P Q P Q Q Q P S S...

Страница 989: ...Protective Elements 989 MCDLV4 DOK HB MCDLV4 2E Pr Q P Q P Qr...

Страница 1023: ...Protective Elements 1023 MCDLV4 DOK HB MCDLV4 2E...

Страница 1070: ...Supervision 1070 MCDLV4 DOK HB MCDLV4 2E...