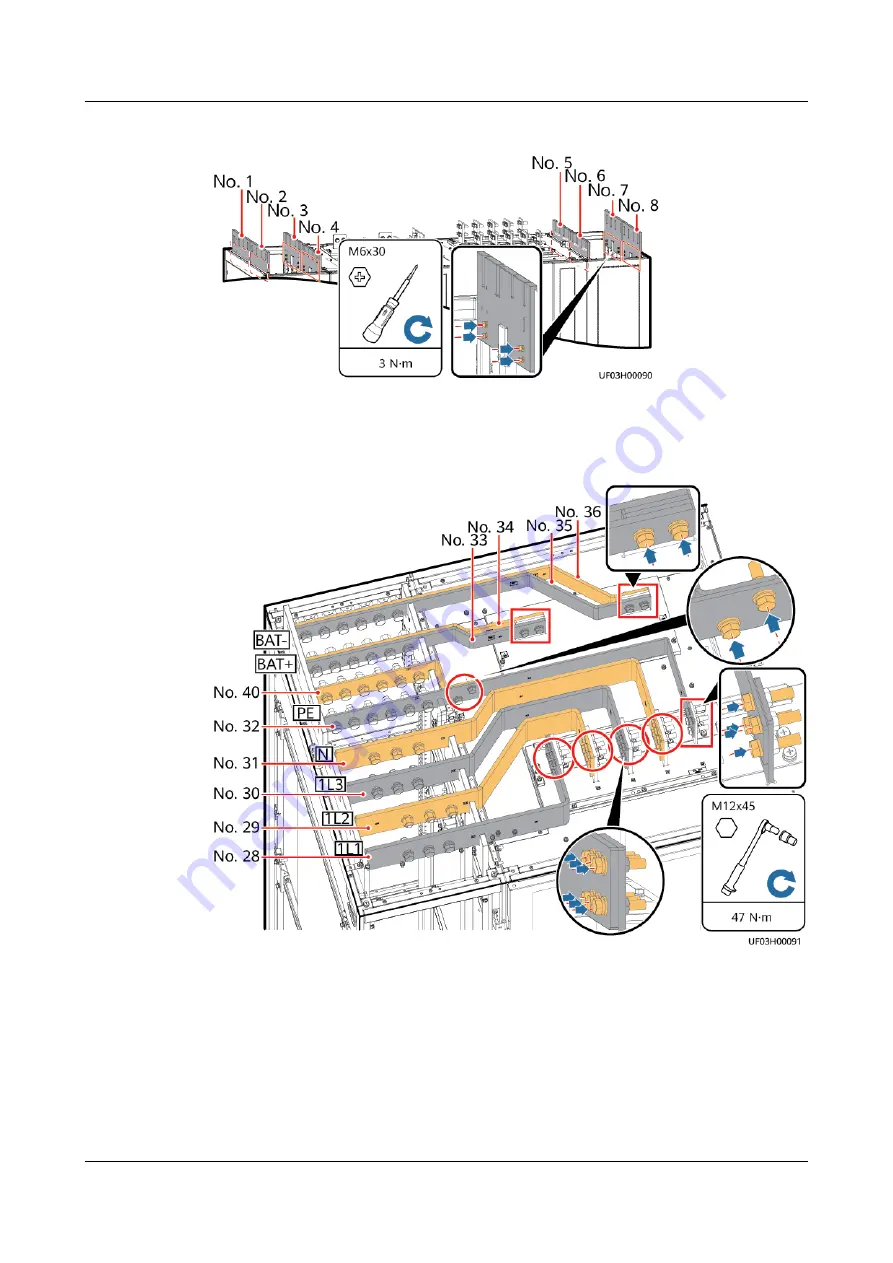

Figure 6-65 Installing epoxy boards

Step 3 Install batteries (No. 33 to 36) and mains input copper bars (No. 28 to 32 and 40)

from right to left.

Figure 6-66 Installing copper bars

Step 4 Install bypass input copper bars (No. 20 to 23) and output copper bars (No. 24 to

27) from right to left.

UPS5000-H-(1200 kVA-1600 kVA)

User Manual (100 kVA Power Modules)

6 Installation

Issue 05 (2021-10-13)

Copyright © Huawei Technologies Co., Ltd.

125