SiUS342303E

Special Control

Part 4 Functions and Control

116

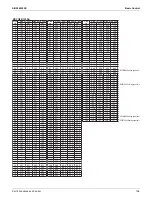

7.2 Oil

Return

Operation

In order to prevent the compressor from running out of oil, the oil return operation is conducted to

recover oil that has flowed out from the compressor to the system side.

Tc: High pressure equivalent saturation temperature

Te: Low pressure equivalent saturation temperature

TsA: Suction pipe temperature detected by thermistor R5T

Ts: Suction pipe before accumulator temperature

7.2.1 Oil Return Operation in Cooling Operation

Part name

Electric

symbol

Function of functional part

Compressor motor

M1C, M2C

Constant low pressure control

Fan motor

M1F, M2F

High pressure control

Electronic expansion valve (Heat exchanger main)

Y1E

Same as normal control

Electronic expansion valve (Heat exchanger left)

Y6E

Electronic expansion valve (Refrigerant cooling IPM)

Y2E

Same as normal control

Electronic expansion valve (Subcooling heat exchanger)

Y3E

0 pulse

Electronic expansion valve (Refrigerant auto charge)

Y4E

40 pulse

Electronic expansion valve (Refrigerant cooling air)

Y5E

Same as normal control

Solenoid valve (Oil separator oil return)

Y1S, Y2S

ON

Solenoid valve (Hot gas bypass)

Y3S

Same as normal control

Solenoid valve (Accumulator oil return)

Y4S

ON

Solenoid valve (Four way valve)

Y5S

Hold

Solenoid valve (Injection)

Y6S

ON

Ending condition

A lapse of 3 minutes

TsA – Te < 3

C (5.4°F)

A lapse of 6 minutes while the frequency is

more than that of oil return operation.

&

OR

Indoor unit actuator

Oil return operation

Fan

Thermostat ON unit

Remote controller setting

Non-operating unit

OFF

Thermostat OFF unit

Remote controller setting

Electronic expansion valve

Thermostat ON unit

Normal control

Non-operating unit

224 pulse

Thermostat OFF unit

Forced thermostat ON (PI control)

Low-temperature hydrobox unit actuator

Oil return operation

Pump

Thermostat ON unit

Normal control

Non-operating unit

Normal control

Thermostat OFF unit

Normal control

Electronic expansion valve

Thermostat ON unit

Normal control

Non-operating unit

224 pulse

Thermostat OFF unit

Forced thermostat ON (PI control)

Содержание VRV EMERION RXYQ-AATJA

Страница 1: ...Service Manual Heat Pump 60 Hz RXYQ AATJA 208 230 V RXYQ AAYDA 460 V SiUS342303E...

Страница 380: ...Check SiUS342303E 373 Part 6 Service Diagnosis Reference Reference CHECK 7 Refer to page 379 CHECK 8 Refer to page 380...

Страница 405: ...SiUS342303E Wiring Diagrams Part 7 Appendix 398 RXYQ72 96 120 144 168 192 216 240AAYDA C 2D140769B...

Страница 406: ...Wiring Diagrams SiUS342303E 399 Part 7 Appendix 1 2 Indoor Unit FXFQ07 09 12 15 18 24 30 36 48TVJU 3D086460B...

Страница 407: ...SiUS342303E Wiring Diagrams Part 7 Appendix 400 BYCQ125BGW1 Self Cleaning Decoration Panel for FXFQ TVJU 3D076375A...

Страница 410: ...Wiring Diagrams SiUS342303E 403 Part 7 Appendix FXEQ07 09 12 15 18 24PVJU 3D098557A...

Страница 411: ...SiUS342303E Wiring Diagrams Part 7 Appendix 404 FXDQ07 09 12 18 24MVJU C 3D050501C...

Страница 413: ...SiUS342303E Wiring Diagrams Part 7 Appendix 406 FXMQ07 09 12 15 18 24 30 36 48 54PBVJU 3D093209B...

Страница 416: ...Wiring Diagrams SiUS342303E 409 Part 7 Appendix FXHQ12 24 36MVJU 3D048116C...

Страница 417: ...SiUS342303E Wiring Diagrams Part 7 Appendix 410 FXAQ07 09 12 18 24PVJU 3D075354F...

Страница 423: ...SiUS342303E Wiring Diagrams Part 7 Appendix 416 1 3 2 Energy Recovery Ventilator VAM Series VAM300 470 600GVJU 3D073269D...

Страница 424: ...Wiring Diagrams SiUS342303E 417 Part 7 Appendix VAM1200GVJU 3D073270D...