66

Bosch Rexroth AG

| Tightening Technology

3 608 878 300

System 350

| 3 608 878 300/2019-03

4.2.1.2

Output drives

If output drives not approved by Bosch Rexroth are used, Bosch Rexroth assumes no responsibility of

correct function of the system.

The following boundary conditions are to be observed for connection of non-approved output drives:

•

The measurement transducer is to be kept free from transverse and axial forces.

•

For high-mass output drives, abrupt changes in speed are to be avoided.

•

Friction losses of third-party output drives influence the torque range of tightening spindle.

•

Transmission ratios over / below 1 of third-party output drives influence the speed range of tightening

spindle.

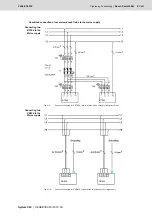

Straight output drive

A straight output drive is generally used with straight, easy to access tightening applications. The straight

output drive consists of a spring-loaded spline shaft. The range of spring of the spline shaft is used to

guide the tool over the entire length of engagement, without having to guide the entire tightening spindle.

Offset output drive

Offset output drives are recommended for tightening applications with e. g. tight bolt-hole circles or

tightening positions that are difficult to access. The side-by-side arrangement is described further below.

Offset output drive

with integrated

measurement

transducer

The torque is measured directly on the output drive shaft in offset output drives with 3VMC and 4VMC

integrated measurement transducers. This further increases the reliability of the tightening system and,

thus, the process reliability. Especially tightenings in small spaces, such as for cylinder head cover or

bearing caps in engines, often require offset output drives. Here, the compact design of the integrated

measurement transducer permits a space-saving arrangement of several spindles in a small circle.

With any adapter, an additional measurement transducer can be integrated between VMC and planetary

gearbox for extra system security. This measurement transducer can also be used as a part of an

emergency strategy if one of the two transducers fails. This increases the availability of the tightening

system even more. The redundant measurement transducer is connected via the 3AR or 4AVR redundant

adapter. The efficiency of the VMC offset output drive has to be taken into account when comparing the

measured values from both measurement transducers.

If a redundant measurement transducer is not used, the 3VMC is installed directly at the planetary

gearbox; the 4VMC requires a 4AVG adapter.

As of version 2.600 of the

Rexroth Tightening System 350

, the offset output drives which are docking-

enabled are supported with integrated VMC...-SD/-SP (external square) / VMC...-QC (quick-change

chuck) measurement transducer.

Angle head

If a tightening spindle cannot be positioned perpendicular to the tightening position in a tightening

application, the use of angle heads as an output drive for the tightening spindle is recommended.

To ensure trouble-free operation, the angle head must always be operated with an output drive axial

compensator (e. g. straight output drive). If this is not possible, e. g. due to space reasons, the user must

take appropriate measures to ensure that the axial forces determined according to the following

calculation are not exceeded.

NOTICE

Damage or destruction

Damage to or destruction of the output drive due to radial forces

When constructing the tightening station, ensure that no radial forces are exerted on the output

drive during operation.

Use steel output drive components, if necessary. In this case, please contact Bosch Rexroth.

The applied third-party output drives have to be applied according to external conditions and the used

tightening spindles. Particularly the mass ratios are to be observed. At high accelerations of high masses,

overload errors and, in worst case, damage at the tightening spindle may occur.

Содержание Rexroth Tightening System 350

Страница 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Страница 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Страница 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Страница 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...