5 - 11

CHAS

FREIN AVANT ET FREIN ARRIERE

VORDER- UND HINTERRADBREMSE

FRENO ANTERIORE E POSTERIORE

VORDER- UND HINTERRADBREMSE

VORDERRADBREMSE

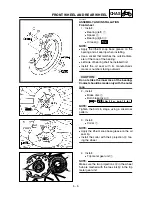

Demontage-Arbeiten:

1

Bremsschlauch demontieren

2

Bremssattel demontieren

3

Hauptbremszylinder demontieren

Demontage-Arbeiten

Reihen-

folge

Bauteil

Anz.

Bemerkungen

Vorbereitung für den Ausbau

VORDERRADBREMSE DEMONTIEREN

Das Motorrad am Motor aufbocken.

Bremsflüssigkeit ablassen.

WARNUNG

Das Motorrad gegen Umfallen sichern.

Siehe unter “AUSBAU”.

1

Bremsschlauchabdeckung

1

2

Halterung

1

3

Schraube (Halterung)

2

Nur lockern.

4

Hohlschraube

2

5

Bremsschlauch

1

6

Haltestift-Abdeckschraube

1

Beim Lockern des Haltestiftes ausbauen.

7

Haltestift

1

Beim Zerlegen des Bremssattels lokkern.

8

Bremssattel

1

9

Bremshebel

1

10

Hauptbremszylinder-Halterung

1

11

Hauptbremszylinder

1

2

1

2

3

3

FREIN AVANT ET FREIN ARRIERE

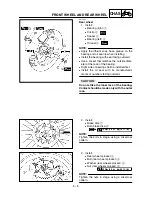

FREIN AVANT

Organisation de la dépose:

1

Dépose du tuyau de frein

2

Dépose de l’étrier de frein

3

Dépose du maître-cylindre de frein

Organisation de la dépose

Ordre

Nom de pièce

Qté

Remarques

DEPOSE DU FREIN AVANT

AVERTISSEMENT

Bien soutenir la machine afin qu’elle ne risque

pas de se renverser.

Préparation pour la dépose

Maintenir la machine en plaçant un support

approprié sous le moteur.

Vidanger le liquide de frein.

Se reporter à “POINTS DE DEPOSE”.

1

Logement de durit de frein

1

2

Support de durit de frein

1

3

Boulon (support de durit de frein)

2

Desserrer uniquement.

4

Boulon-raccord

2

5

Durit de frein

1

6

Bouchon de goupille de plaquette

1

Déposer lors du desserrage de la goupille de plaquette.

7

Goupille de plaquette

1

Desserrer lors du démontage de l’étrier.

8

Etrier de frein

1

9

Levier de frein

1

10

Demi-palier de maître-cylindre de frein

1

11

Maître-cylindre de frein

1

2

1

2

3

3

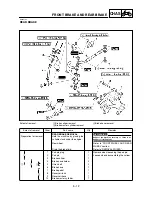

FRENO ANTERIORE E POSTERIORE

FRENO ANTERIORE

Portata dello smontaggio:

1

Rimozione del flessibile del freno

2

Rimozione della pinza del freno

3

Rimozione della pompa del freno

Portata dello smontaggio

Ordine

Denominazione

Quantità

Osservazioni

Preparazione per la rimozione

RIMOZIONE FRENO ANTERIORE

Mantenere il veicolo posizionando un supporto

idoneo sotto al motore.

Scaricare il liquido dei freni.

AVVERTENZA

Sostenere saldamente il veicolo in modo che non ci sia

il rischio che si rovesci.

Fare riferimento a “PUNTI DI RIMOZIONE”.

1

Coperchio tubo flessibile del freno

1

2

Supporto tubo flessibile del freno

1

3

Bullone (supporto tubo flessibile del freno)

2

Allentare soltanto.

4

Bullone di giunzione

2

5

Flessibile del freno

1

6

Spina pastiglie

1

Rimuovere nell’allentare la spina delle pastiglie.

7

Spina pastiglie

1

Allentare quando si smonta la pinza.

8

Pinza del freno

1

9

Leva del freno

1

10

Staffa pompa del freno

1

11

Pompa del freno

1

2

1

2

3

3

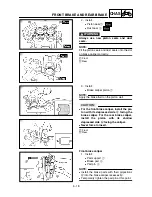

Summary of Contents for WR250F(P)

Page 604: ...5 67 CHAS REAR SHOCK ABSORBER 8 Install Band 1 Taillight connector 2...

Page 692: ......

Page 693: ......