2000 MS Hardware Maintenance

118

GC Maintenance

their lowest possible level. For the MS detector an oxygen filter should be

employed as well

Varian supplies several types of carrier gas purifiers. These include a combined

moisture / hydrocarbon trap, indicating moisture trap, indicating or non-indicating

oxygen traps and a combined moisture / hydrocarbon / oxygen trap. While the

choice of purifier depends on the individual configuration and performance

expectations, the following configuration is recommended for maximum carrier

gas purity and protection.

The carrier gas should first pass through a hydrocarbon trap, then an indicating

moisture filter, then a high capacity oxygen trap and finally through an indicating

oxygen trap. As moisture reduces the effectiveness of an oxygen trap, a moisture

trap should always be placed in front of an oxygen trap. When the indicating

oxygen trap begins to change color, the high capacity oxygen trap should be

changed immediately. The moisture trap should also be changed immediately

when it changes color to prevent breakthrough of moisture to the oxygen trap.

The filters supplies by Varian are mounted either on the rear panel of the

instrument or on a filter stand, depending on when the instrument was

purchased. Follow one of the two procedures below to replace the filter.

If Filters are Mounted on the Rear of the GC:

Gas purifiers supplied by Varian and most other chromatography suppliers are

equipped with 1/8

″

Swagelok fittings. This facilitates easy removal and

replacement of purifiers. In addition gas purifiers are sealed at both ends for

protection. Purifiers should only be uncapped when you are about to install them.

1. Turn off the carrier gas supply at the input regulator. Note the operating

pressure to allow resetting to this value after the purifier is installed.

2. Carefully open the carrier gas fitting at the inlet bulkhead to the GC or the

existing carrier gas purifier. Wait for the release of carrier gas pressure

before removing the fitting.

3. Identify the recommended direction of carrier gas flow on the purifier. This is

normally indicated by an arrow on the side of the purifier. Remove the inlet

cap from the purifier and immediately connect the carrier gas inlet line to the

purifier inlet.

4. Remove the outlet cap from the purifier, turn the carrier supply back on and

allow the carrier gas to purge through the purifier for 0.5 - 1 minutes.

5. Connect the outlet of the gas purifier to the inlet of the GC or the inlet of the

next purifier, if used. If a new connection is being made, use chromatography

grade copper tubing and new Swagelok fittings.

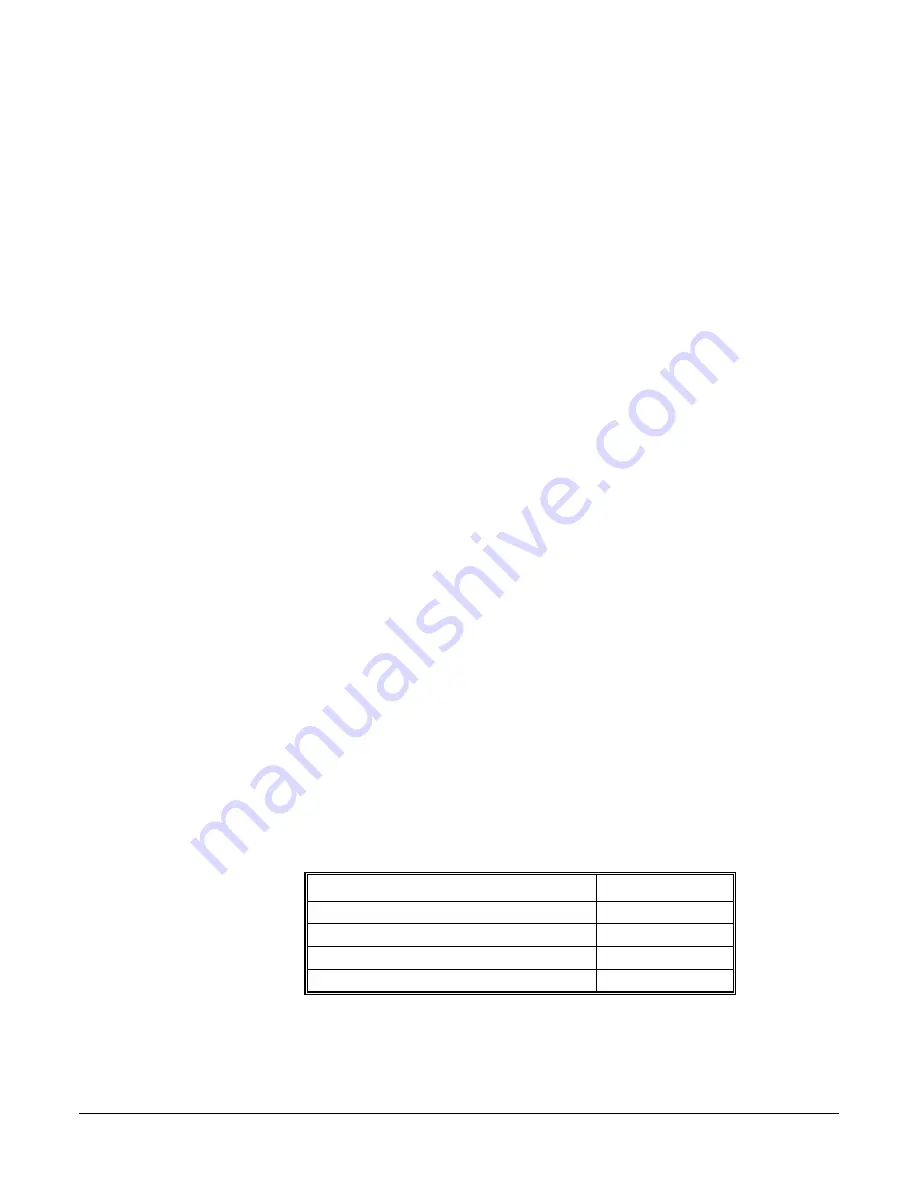

The following are the rear mounted gas purifiers available from Varian.

Purifier Part

Number

High capacity oxygen trap

03-949770-02

Indicating oxygen trap

88-501019-00

Combined hydrocarbon and moisture trap

03-949862-00

Indicating moisture trap

01-900007-00