03-914978-00:1

119

GC Maintenance

If Filters are Mounted on a Separate Stand:

Filters have been supplied in either a single combined

moisture/hydrocarbon/oxygen filter arrangement or as two filters (a

moisture/hydrocarbon filter and oxygen filter). Two valves automatically take care

of stopping and starting the gas flow. Each filter is replaced using the following

procedure:

1. Remove the saturated filter by unscrewing the knurled nut. The system

remains under pressure.

2. Check the O-rings for hairline cracks. Cracked rings may cause leakage. If

cracks are found replace all rings.

3. Remove the filter from the packaging and remove the self-adhesive foil from

the bottom of the filter. Place the filter onto the connecting unit.

4. Place the knurled ring nut over the filter and screw it on, while pressing the

filter down. Some force may be necessary if the system is under high

pressure.

5. Carefully check the connection for leakage. This is important as oxygen and

moisture from the air enter the system through the tiniest leaks.

6. Mark the date of installation on the calendar in the filter label with a felt tip

pen.

NOTE: Review the instructions supplied with the replacement filters.

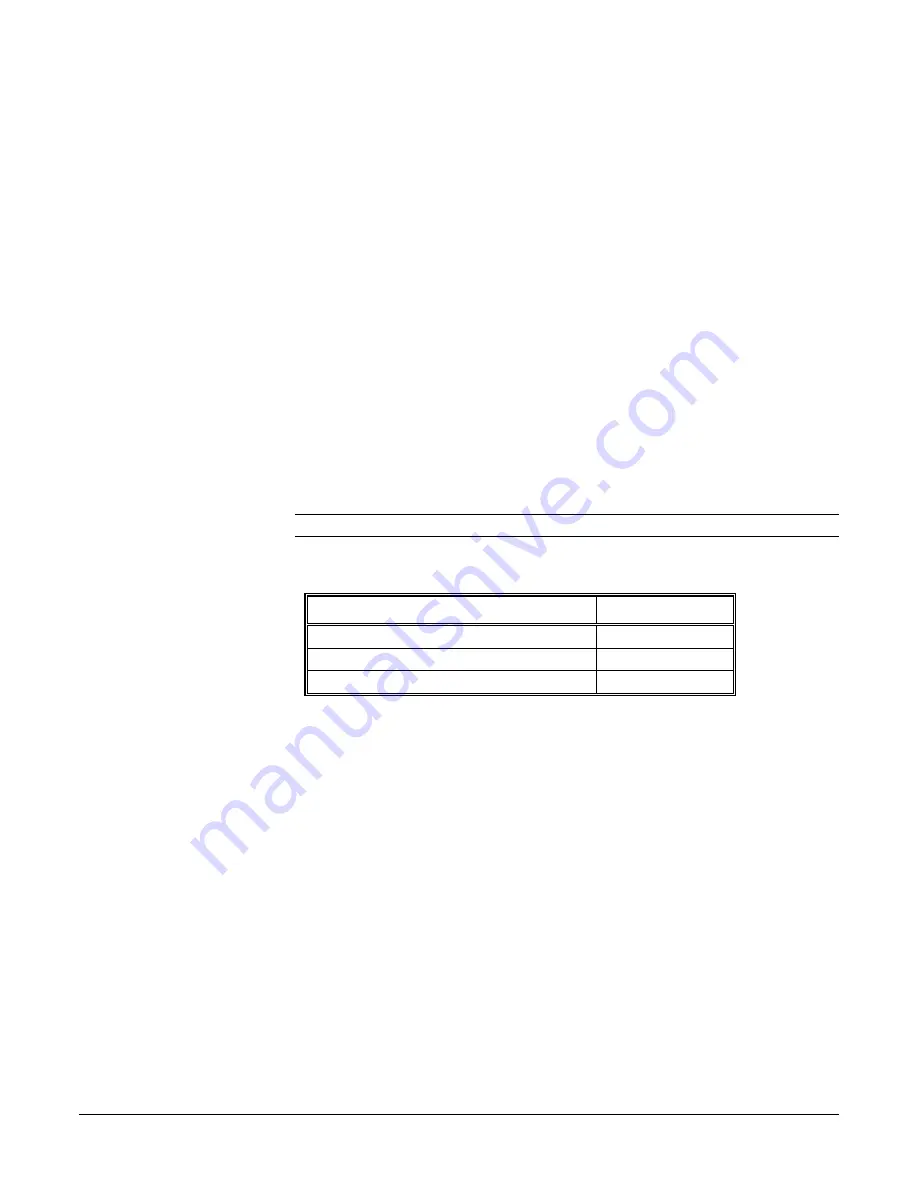

The following are the stand-alone gas purifiers available from Varian.

Purifier Part

Number

Indicating oxygen trap

CP17970

Indicating moisture trap

CP17971

Combined hydrocarbon/moisture/oxygen trap

CP17973

Injector Maintenance

The injector is the component of the Gas Chromatograph that requires the most

frequent maintenance. This is due to the fact that the sample is deposited in the

injector, thus leading to potential contamination and build up of non-volatile

deposits. The most frequent injector maintenance is septum replacement. In

addition insert replacement and injector cleaning are very common. As septum

replacement is common to all liquid injectors on the 3800 this procedure is

presented first, followed by specific maintenance procedures for the individual

injectors.

Septum Replacement

The injector septum is an expendable part and must be replaced on a routine

basis. The frequency of replacement depends on the number of injections and

whether the injections are by hand or with an autosampler. In general the septum

should be replaced every 50 - 100 injections or when symptoms of a septum leak

are seen. These symptoms include changing retention times, reduced detector

response or a drop in column head pressure. The latter symptom is not always

valid as some injectors, such as the 1079, are pressure controlled. With a