03-914978-00:1

135

Troubleshooting

Check the Axial Modulation Setting

Check whether the axial modulation is set too high or too low, proceeding as

follows:

1. Click on Set Points from Manual Control. Make sure the axial modulation is

set between 2.5 and 5 volts. If you adjust the axial modulation, check several

cal gas ions for resolution (e.g., m/z = 131 and 414).

2. Check whether axial modulation is working properly, proceeding as follows:

3. Enter System Control, turn trap and cal gas ON. Click near m/z 131, to

expand the mass range + 5 about m/z 131. Click on Set Points. Change the

Axial Modulation by several volts and click on Apply. Confirm the shift of

mass 131. Return axial modulation to initial value.

4. Enter Diagnostics and run tests to completion. Confirm the axial modulation

is working properly.

5. Make sure that the axial modulation readback is within 20% of the set point.

If the axial modulation readback is out of this range, it will usually result from

improper installation of the trap oven causing a shorted endcap.

6. If oven is properly assembled and axial modulation is out of range, contact

your Varian Customer Support Representative.

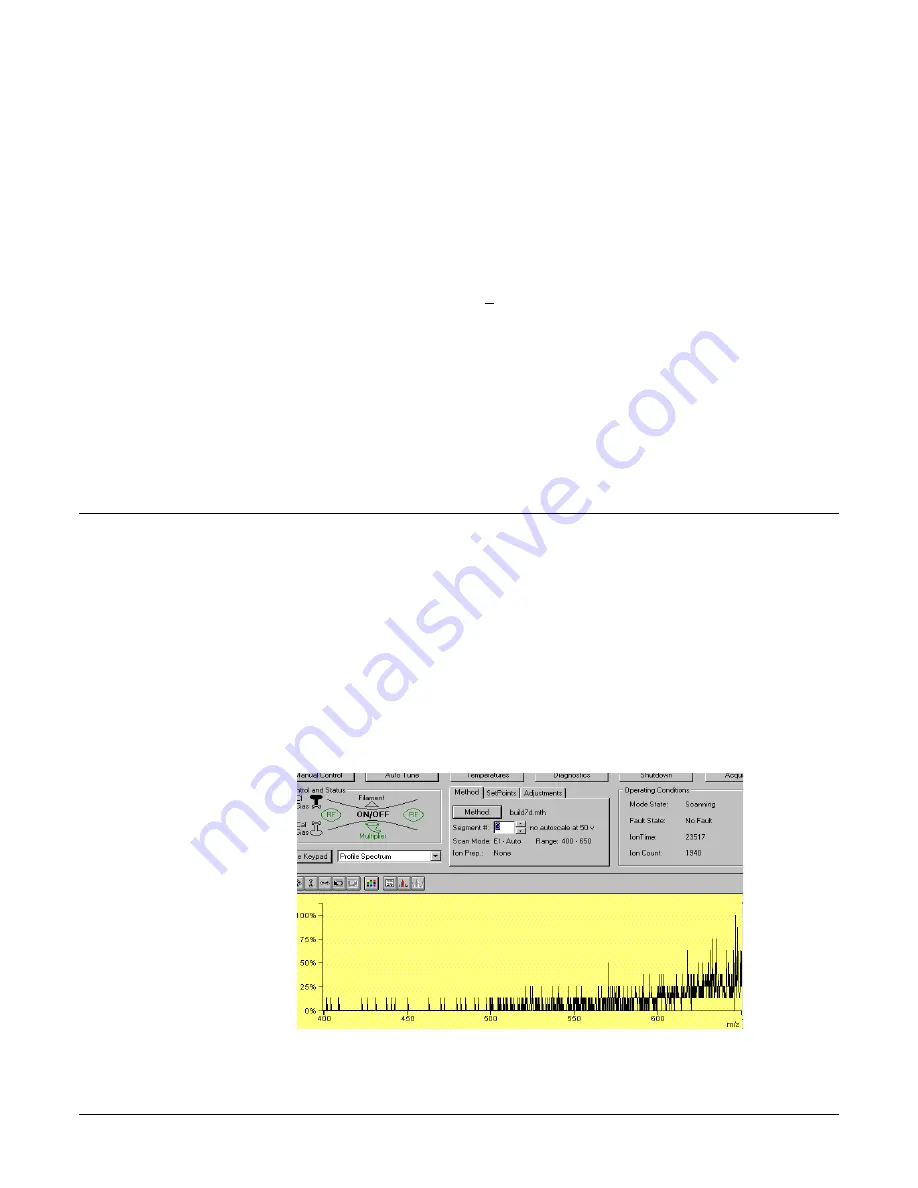

What To Do If There is a High Baseline at High Masses

If the baseline on the instrument page increases sharply between masses 400

and 650, you should investigate whether there are particles on the electrode

surface.

Check whether there are particles on the trap electrode surfaces, proceeding as

follows:

1. Develop method for EI/AGC ON for mass range 400 to 650. Enter System

Control and activate this method.

2. Turn on RF and the electron multiplier (Filament is OFF).

3. Examine the spectrum, and notice whether the baseline increases

exponentially at high masses.

•

If the baseline ramps up, shut down Saturn, then carefully clean the

electrode surfaces with a lint-free cloth.