2000 MS Hardware Maintenance

12

Functional Description

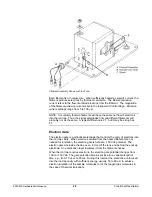

The electronics section fan draws air from the back, and blows it across the

SAP/WAVE and power boards in the electronics compartment. Hot air from the

GC oven does not affect the MS as long as the system is at least six inches from

a wall. The power board supplies power to the electronics compartment fan.

Diffusion Pump System

The GC/MS Diffusion pump system has three cooling zones, each with its own

fan mounted in the rear of the instrument.

Cooling Zones

Zone 1

is the upper part of the analyzer compartment. Its purpose is to provide

forced air-cooling for the Peltier baffle’s heat sink. It also provides cooling for the

manifold electronics. The upper fan on the rear panel pulls air in through the

front of the instrument. The air is drawn over the manifold electronics, ducted

over the Peltier baffle’s heat sink, and expelled through the rear of the

instrument. The diffusion pump controller monitors operation of this fan. Fan

failure will trigger a system shutdown.

CAUTION

The Peltier Baffle ducting must be left in position at all times, or the Peltier

baffle will overheat allowing back streaming pump vapor to contaminate the

analyzer.

Zone 2

is the electronics compartment, diffusion pump controller, and RF

generator board. Its purpose is to cool the majority of the instrument’s printed

circuit boards. The mid level fan on the rear panel pulls air in from two directions.

The primary cooling air supply is pulled in through the front of the instrument,

over the power board and SAP/Wave board, and expelled through the rear of the

instrument. A secondary air supply is pulled in through the left side panel, ducted

over the RF generator board, the diffusion pump controller, and then merges with

the primary airflow.