03-914978-00:1

35

Chemical Ionization Options

CI reagent gases may be hazardous. Use proper protection when installing the

reagent gas.

1. Enter the System Control and select the Manual Control tab dialog.

2. Make sure that the electron multiplier, filament, and RF voltage are all off. The

Multiplier, Filament, and RF text should be red or black - not green.

NOTE: Two solenoid-operated valves control the flow of CI reagent gas into the

manifold. The valves are opened and closed by clicking on the CI button on the

Instrument Control display. A needle valve controls the amount of reagent gas

flowing into the manifold. The needle valve is mounted directly behind the door

of the mass spectrometer. The needle valve is adjusted manually by using the

knob labeled CI GAS. Turning the knob clockwise increases the flow of reagent

gas into the manifold. See Functional Block Diagrams in the

Turbomolecular

Vacuum Pump

or

Diffusion Pump Vacuum System

.

3. Verify that the CI gas solenoid valves are closed. When these valves are closed,

the CI Gas icon to the left of the ion trap symbol is not green. (If the CI icon is

green, click on the icon so that it turns to red or black.)

4. Install a two-stage pressure regulator on the reagent gas cylinder or lecture

bottle. Tighten the connection securely.

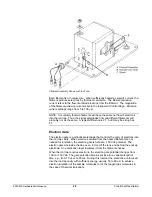

NOTE: A two-stage pressure regulator typically consists of the following

components: Secondary valve, Pressure adjustment valve, Supply pressure

gauge, and Delivery pressure gauge

5. Reagent gas is turned on and off with the Main valve on the cylinder or lecture

bottle. The secondary valve on the pressure regulator is next in line. This valve is

used for coarse control of the flow of gas from the gas cylinder up to the pressure

adjustment valve. The supply pressure gauge is used to monitor the gas

pressure in the bottle. The pressure adjustment valve is used to set the head

pressure of the gas delivered to the mass spectrometer.

6. Connect one end of the 1/8" OD gas supply line to the pressure regulator.