2000 MS Hardware Maintenance

148

Troubleshooting

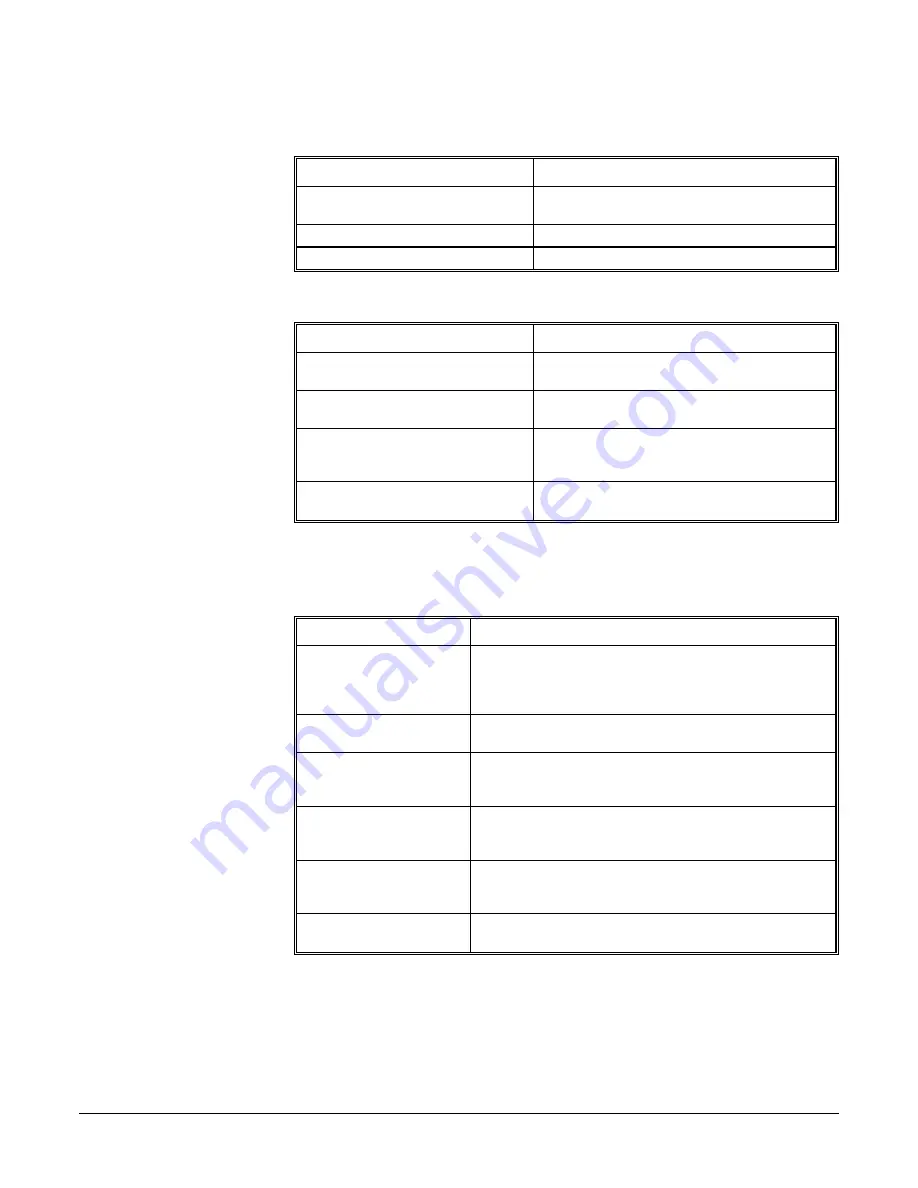

Correction of Leading Sample Peaks (Reverse

Tailing)

Symptom Solution

Column overhead due to injection of

excessive amounts of a component

Dilute the sample, or perform a split injection.

Degradation of the stationary phase

Change the column.

Carrier gas velocity is too low

Increase the carrier flow rate.

Correction of Poor Resolution

1

Symptom Solution

Column temperature or program is

not optimized

Modify the method (e.g., slow the column ramp

rate) to improve the separation

Carrier gas flow is not optimized

Decrease the carrier gas linear velocity to

improve the resolution.

Column cannot separate certain

species, (e.g., those with similar

boiling points)

Use a more polar column.

Column stationary phase is

degraded, resulting in poor efficiency

Replace the column.

1

Peaks are not well separated, e.g., 2,6-dimethylphenol and

2-ethylhexanoic acid in the COLTEST mixture.

Lack of Reproducibility of Peak Size

Symptom Solution

Leaking or partially

plugged syringe

Visually check that the syringe is pulling up the sample.

Check that the nut is tight. Flush the syringe with solvent.

Heating the solvent in a hot injector may help if the syringe

is plugged; otherwise, replace the syringe.

Leak at the septum

Replace the septum regularly and ensure that the septum

nut is tight.

Improper installation of

column in the injector, or a

leak at the column inlet

Check the installation of the column in the injector.

Tighten the capillary column nut.

Sample is being absorbed

by active surfaces in the

injector or column

Change the injector insert. Remove the front 15 cm of the

column, or replace the column.

Incomplete vaporization of

sample in the injector

Increase the injector temperature (1077,1078 or 1079).

Or increase the maximum temperature to which the

injector is programmed (SPI or 1079).

1077,1078 or 1079 splits

too soon

Confirm that the switch time is chromatographically

optimized.