6–74

Replacement Procedures

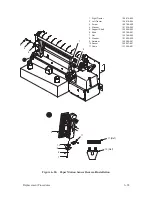

Hammer Driver and Power Supply PCBAs

(Figure 6–25)

Removal

WARNING

High electrical potentials are present on the hammer driver and power

supply PCBA capacitors when the printer is powered down. To avoid

shock hazard and damage to the equipment, wait at least 5 minutes after

powering down before removing the hammer driver or power supply

PCBAs.

NOTE: The hammer driver and power supply PCBA locations are labelled

at the top of the card cage. Removal/installation is the same for all

cards. The Power Supply 3 PCBA is illustrated.

1. Remove the right side panel as described on page 6–4.

2. Loosen two screws (1) and remove the cover (2).

3. Lift the ejection levers (3) and slide the PCBA (4) out of the card cage

(5).

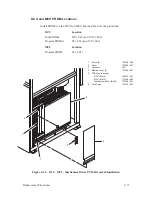

Installation

CAUTION

Installing a PCBA in the wrong slot will damage the PCBA and

connector.

1. Slide the PCBA into the correct slot in the card cage.

2. Engage the ejection levers and close to seat the PCBA.

3. Install the cover and tighten two screws.

4. Install the right side panel as described on page 6–4.

Summary of Contents for P9012

Page 1: ...P N 132305 001 Rev E P9012 Multifunction Line Printer...

Page 49: ...2 31 Principles of Operation Power Supply PCBAs 1 3 SHORT OPEN Figure 2 21 Power Supply PCBA...

Page 58: ...2 40 Principles of Operation...

Page 84: ...4 18 Troubleshooting...

Page 118: ...5 34 Alignments and Adjustments...

Page 203: ...6 85 Replacement Procedures This page intentionally left blank...

Page 214: ...6 96 Replacement Procedures...

Page 236: ...A 22 Power Paper Stacker Maintenance...

Page 246: ...D 2 Torque Table...

Page 254: ...Index 6...

Page 255: ......

Page 256: ...132305 001 Rev E...