2–5

Principles of Operation

The Hammer Bank

In order to use matrix printing, you must have a method to print the required

dots. The P9012 uses the hammer bank.

The hammer bank contains a number of print hammers mounted on a shuttle

that can move back and forth horizontally. The shuttle prints a full line of

dots during each cycle of back and forth motion.

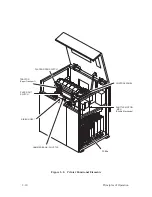

Each hammer consists of a stiff leaf spring attached at one end to the hammer

bank with a screw (Figure 2–4). The end opposite the screw has a pointed tip

attached. A permanent magnet keeps all the hammers retracted and under

tension. Each hammer has a magnetic coil which when energized counteracts

the permanent magnet, causing the hammer to release and strike the ribbon

and paper, leaving a dot (Figure 2–5). After printing, the rebounding hammer

is recaptured by the permanent magnet.

MAGNET

PAPER IRONER

PLATEN

PAPER

RIBBON MASK

HAMMER BANK COVER

HAMMER TIP

HAMMER SPRING

RIBBON

COIL

COIL

SHUTTLE SHAFT

Figure 2–4. Hammer and Shuttle Arrangement (Typical)

Summary of Contents for P9012

Page 1: ...P N 132305 001 Rev E P9012 Multifunction Line Printer...

Page 49: ...2 31 Principles of Operation Power Supply PCBAs 1 3 SHORT OPEN Figure 2 21 Power Supply PCBA...

Page 58: ...2 40 Principles of Operation...

Page 84: ...4 18 Troubleshooting...

Page 118: ...5 34 Alignments and Adjustments...

Page 203: ...6 85 Replacement Procedures This page intentionally left blank...

Page 214: ...6 96 Replacement Procedures...

Page 236: ...A 22 Power Paper Stacker Maintenance...

Page 246: ...D 2 Torque Table...

Page 254: ...Index 6...

Page 255: ......

Page 256: ...132305 001 Rev E...