Hidden parameters

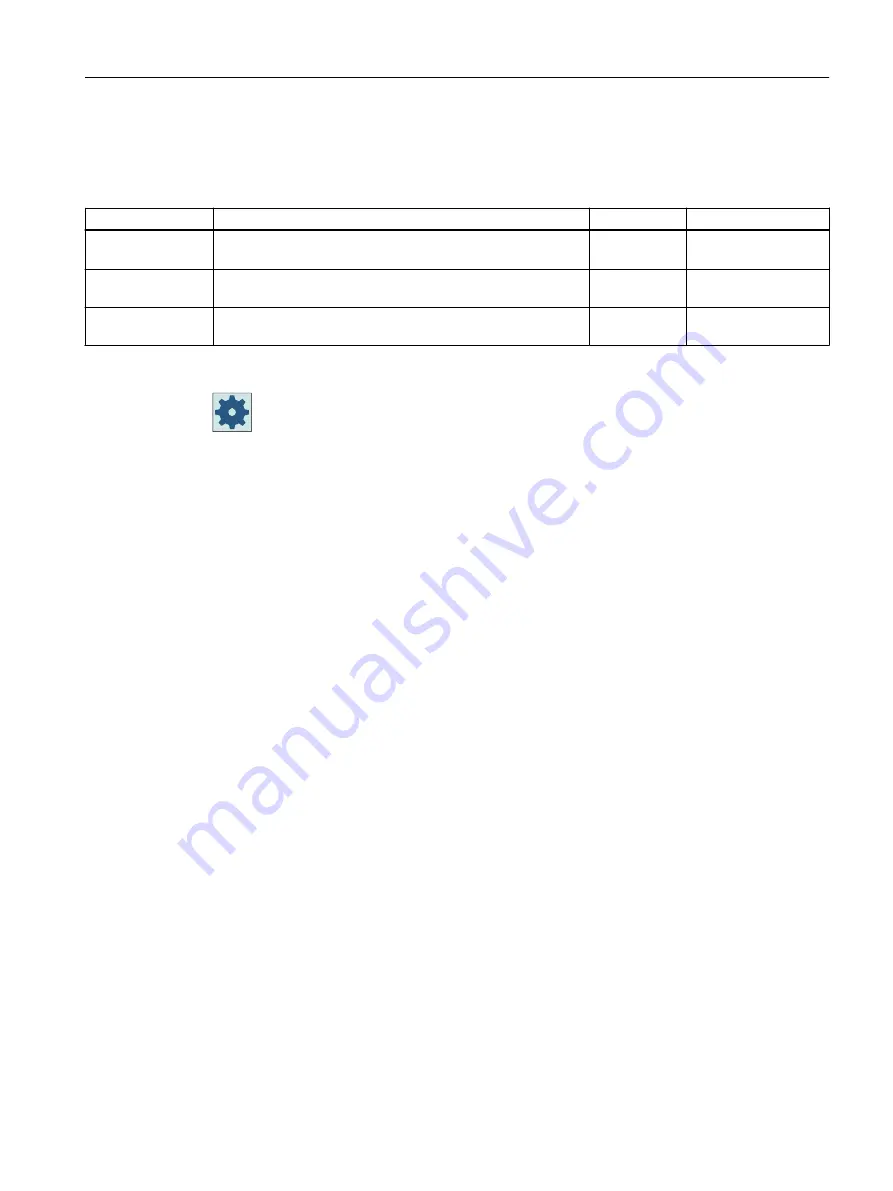

The following parameters are hidden. They are pre-assigned fixed values or values that can be

adjusted using setting data.

Parameter

Description

Value

Can be set in SD

PL (only for G code) Machining plane

Defined in MD

52005

SC (only for G

code)

Safety clearance

1 mm

x

Lift mode

Lift mode before new infeed - (only for ∇, ∇∇∇ base or ∇∇∇

edge)

to RP

Machine manufacturer

Please refer to the machine manufacturer's specifications.

10.5.13

Contour spigot residual material (CYCLE63, option)

Function

When you have milled a contour spigot and residual material remains, then this is automatically

detected. You can use a suitable tool to remove this residual material without having to machine

the whole spigot again, i.e. avoiding unnecessary non-productive motion. The finishing

allowance should be set identically for all machining steps because it does not count as residual

material.

The residual material is calculated on the basis of the milling cutter used for clearing.

It is also possible to run multiple residual material steps one after the other. In this case, the

milling tool should be selected to be smaller by a factor of no more than 3 for each new step.

If you mill several spigots and want to avoid unnecessary tool changeover, clear all the spigots

first and then remove the residual material. In this case, when removing the residual material,

you must also enter a value for the reference tool TR parameter, which, in the ShopTurn

program, additionally appears when you press the "All parameters" softkey. When

programming, proceed as follows:

1. Contour blank 1

2. Contour spigot 1

3. Clear spigot 1

4. Contour blank 2

5. Contour spigot 2

6. Clear spigot 2

7. Contour blank 1

8. Contour spigot 1

Programming technology functions (cycles)

10.5 Contour milling

Turning

Operating Manual, 06/2019, A5E44903486B AB

601