Taking into account the tailstock

0DFKLQLQJIHHGUDWH

5DSLGWUDYHUVH

7RROFKDQJHSRLQW

5HWUDFWLRQSODQH

6DIHW\FOHDUDQFH

;55

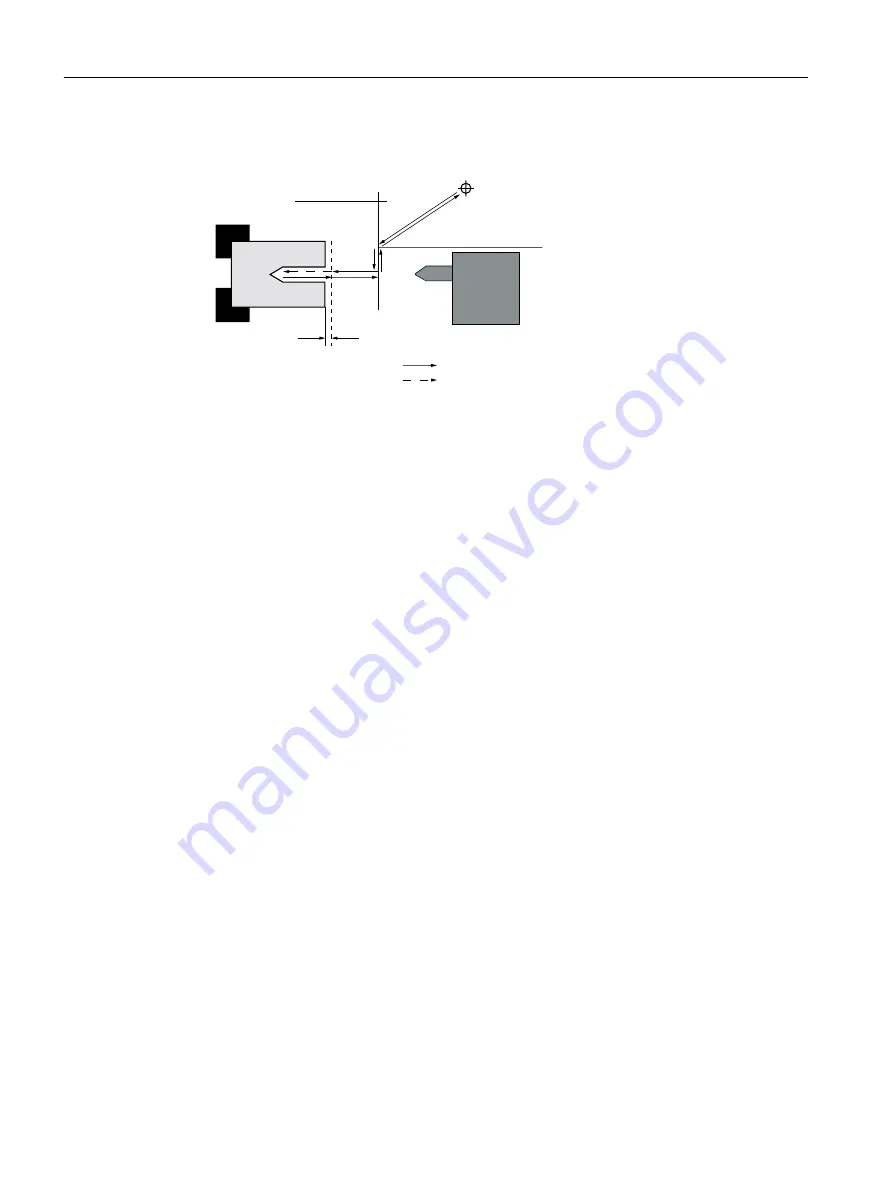

Figure 9-6

Approach/retraction taking into account the tailstock

● The tool traverses in rapid traverse from the tool change point along the shortest path to the

retraction plane XRR from the tailstock.

● After this, the tool traverses in rapid traverse on the retraction plane in the X direction.

● After this, the tool traverses in rapid traverse to the safety clearance.

● Following this, the workpiece is then machined with the programmed machining feedrate.

● After machining, the tool retracts with rapid traverse to the safety clearance.

● The tool then continues to traverse vertically in rapid traverse to the retraction plane.

● After this, the tool traverses in the X direction to the retraction plane XRR from the tailstock.

● From there, the tool traverses in rapid traverse along the shortest path to the tool change

point. If the tool does not need to be changed between two machining processes, the tool

traverses from the retraction plane to the next machining cycle.

You define the tool change point, the retraction plane, the safety clearance, and the retraction

plane for the tailstock in the program header.

See also

Programming the approach/retraction cycle (Page 322)

Program header (Page 300)

9.4.3

Absolute and incremental dimensions

When generating a machining step program, you can input positions in absolute or incremental

dimensions, depending on how the workpiece drawing is dimensioned.

You can also use a combination of absolute and incremental dimensions, i.e. one coordinate

as an absolute dimension and the other as an incremental dimension.

For the face axis (the X axis, in this case), in the machine data it is established whether the

diameter or radius is programmed in absolute or incremental dimensions.

Please refer to the machine manufacturer's specifications.

Creating a ShopTurn program

9.4 Fundamentals

Turning

294

Operating Manual, 06/2019, A5E44903486B AB