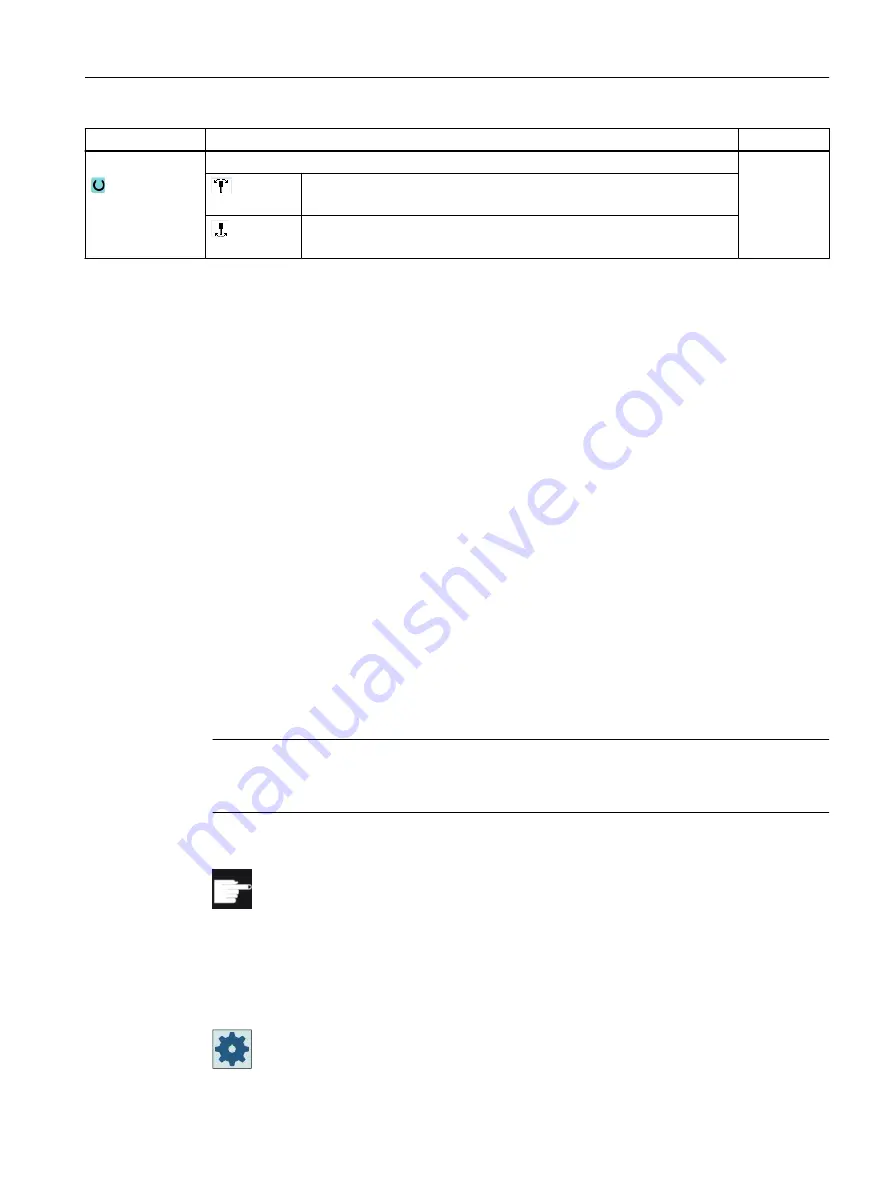

Parameter

Description

Unit

Tool

Tool tip position when swiveling

Tracking

The position of the tool tip is maintained during swiveling.

No tracking

The position of the tool tip changes during swiveling.

10.6.3

High-speed settings (CYCLE832)

Function

The "High Speed Settings" function (CYCLE832) is used to preset data for the machining of

free-form surfaces so that optimum machining is possible.

The call of CYCLE832 contains three parameters:

● Machining type (technology)

● Axis tolerance

● Input of the orientation tolerance (for 5-axis machines)

Machining of free-form surfaces involves high requirements for both velocity and precision and

surface quality.

With the "High Speed Settings" function, you can achieve optimum velocity control depending

on the type of machining (roughing, semi-finishing, finishing/speed or fine finishing/precision).

It is also possible to machine and process very fine structures. For this purpose, the cycle

activates the compressor COMPCAD (for Advanced Surface option) or COMPSURF (for TOP

Surface option).

Note

Programming a cycle

Program the cycle in the technology program before the geometry program is called.

Software option

To use the "High Speed Settings" (CYCLE832) function, you require the "Advanced

Surface" software option.

Default values

You can use the "Default values" softkey to assign default values to the tolerance parameters.

Machine manufacturer

Please observe the information provided by the machine manufacturer.

Programming technology functions (cycles)

10.6 Further cycles and functions

Turning

Operating Manual, 06/2019, A5E44903486B AB

617