W1: Tool offset

18.9 Basic tool orientation

Basic Functions

Function Manual, 09/2011, 6FC5397-0BP40-2BA0

1543

Tool length components

The components of the tool orientation are treated the same as the components of the tool length, with respect to

setting data:

SD42910 $SC_MIRROR_TOOL_LENGTH (Sign change tool wear when mirroring).

SD42950 $SC_TOOL_LENGTH_TYPE (allocation of the tool length components independent of tool type)

Therefore the components are changed respectively and assigned to the geometry axis.

System variable $TC_DPV[t, d]

The purpose of system variable $TC_DPV[t, d] is to allow the simple specification of certain basic orientations

(parallel to coordinate axes) that are required frequently. The permissible values are shown in the table below.

The values in the first and second/third columns are equivalent.

Example:

For milling tools:

$TC_DPV[t, d] = 2 is equal to:

$TC_DPV3[t, d] = 0, $TC_DPV4[t, d] = 0, $TC_DPV5[t, d] = V.

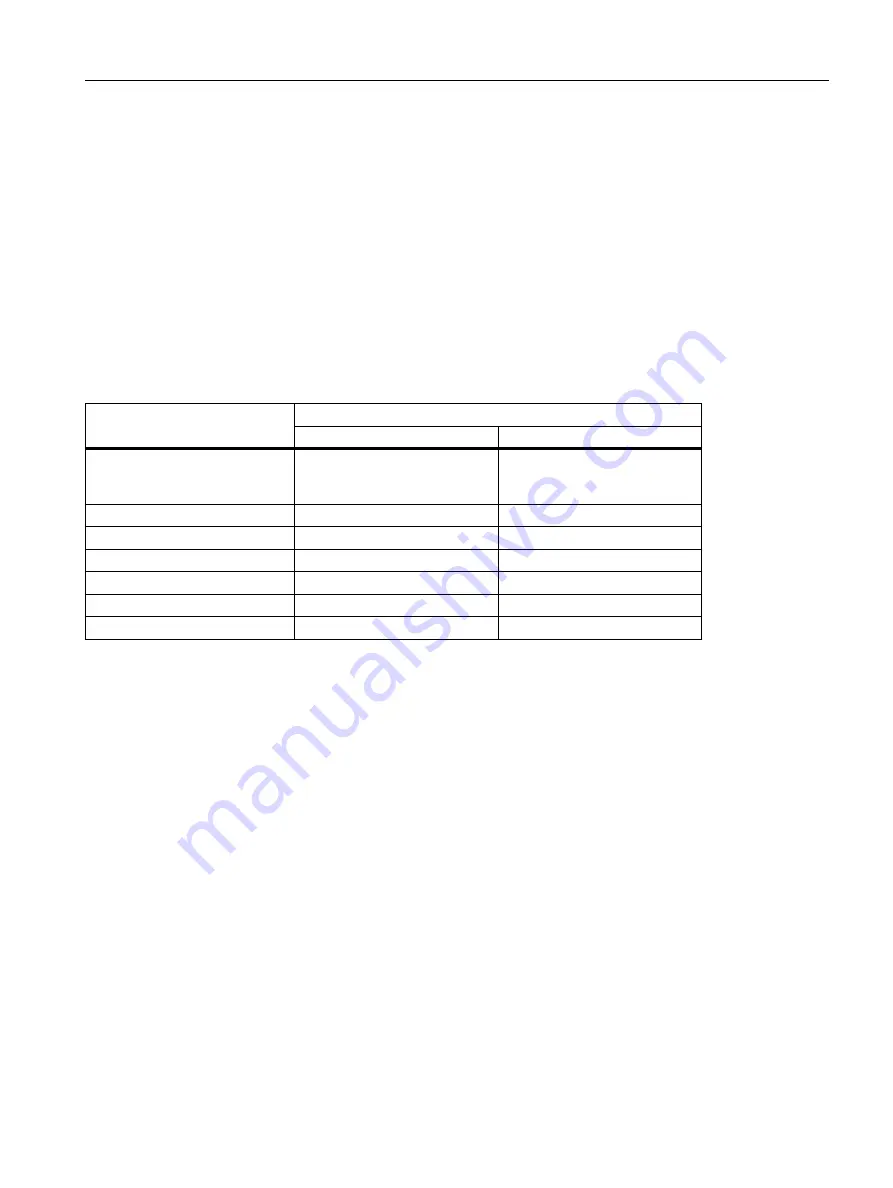

$TC_DPV[t, d]

Basic orientation

Milling tools *

Turning tools *

≤ 0 or > 6

($TC_DPV5[t, d],

$TC_DPV4[t, d],

$TC_DPV3[t, d],) **

($TC_DPV3[t, d],

$TC_DPV5[t, d],

$TC_DPV4[t, d],) **

1

(0, 0, V)

(0, V, 0)

2

(0, V, 0)

(0, 0, V)

3

(V, 0, 0)

(V, 0, 0)

4

(0, 0, -V)

(0, -V, 0)

5

(0, -V, 0)

(0, 0, -V)

6

(-V, 0, 0)

(-V, 0, 0)

*

Turning tools in this context are any tools whose tool type ($TC_DP1[t, d]) is between 400 and

599. All other tool types refer to milling tools.

**

If all three values $TC_DPV3[t, d], $TC_DPV4[t, d], $TC_DPV5[t, d] are equal to zero in this

case, the tool orientation is determined by the active machining plane (default).

V

Stands for a positive value in the corresponding system variables.