2K5

1-3-49

U136

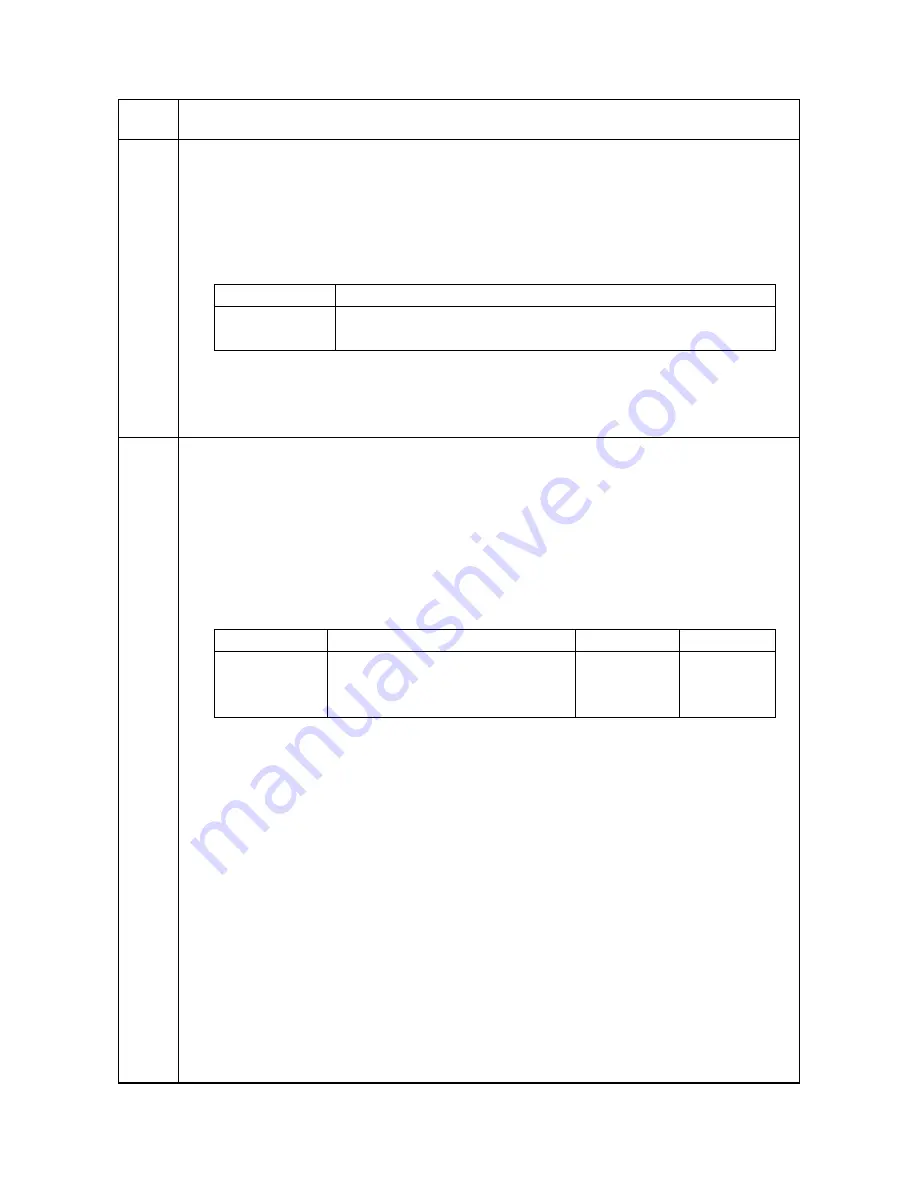

Setting toner near end mode

Description

Sets whether to restrict printing operation when the toner is empty.

Purpose

To set to ON to remove restrictions on printing operation when toner empty is detected.

Setting

1. Press the start key.

2. Select [ON] or [OFF].

Initial setting: OFF

3. Press the start key. The setting is set.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

U144

Setting toner loading operation

Description

Sets toner loading operation after completion of copying. Toner is forcibly evacuated in case the average print-

ing ratio for the number of printed pages assigned by [PAGE] is lower than the ratio defined by [RATIO].

Purpose

To set whether or not toner is loaded on the drum after low density copying. Normally no change is necessary

from the initial setting.

Setting

1. Press the start key.

2. Select the item to be set.

3. Change the setting using the +/- keys.

4. Press the start key. The value is set.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display

Description

ON

Do not display an error or restrict printing operation when the toner is empty

OFF

Display an error and restrict printing operation when the toner is empty

Display

Description

Setting range

Initial setting

MODE

Toner loading operation

1 (ON) / 0 (OFF) 0

PAGE

Number of pages set

1 to 50

5

RATIO

Printing ratio

10 to 40

30

Summary of Contents for TASKALFA 300I

Page 1: ...SERVICE MANUAL Published in February 2010 842K5111 2K5SM061 Rev 1 TASKalfa 300i ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2K5 This page is intentionally left blank ...

Page 22: ...2K5 1 1 8 This page is intentionally left blank ...

Page 196: ...2K5 1 4 52 This page is intentionally left blank ...

Page 252: ...2K5 1 5 56 This page is intentionally left blank ...

Page 274: ...2K5 2 1 20 This page is intentionally left blank ...

Page 310: ...2K5 2 3 28 This page is intentionally left blank ...

Page 347: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 369: ...INSTALLATION GUIDE FOR BUILT IN FINISHER ...

Page 381: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Page 391: ...INSTALLATION GUIDE FOR FAX System ...

Page 407: ......

Page 408: ......