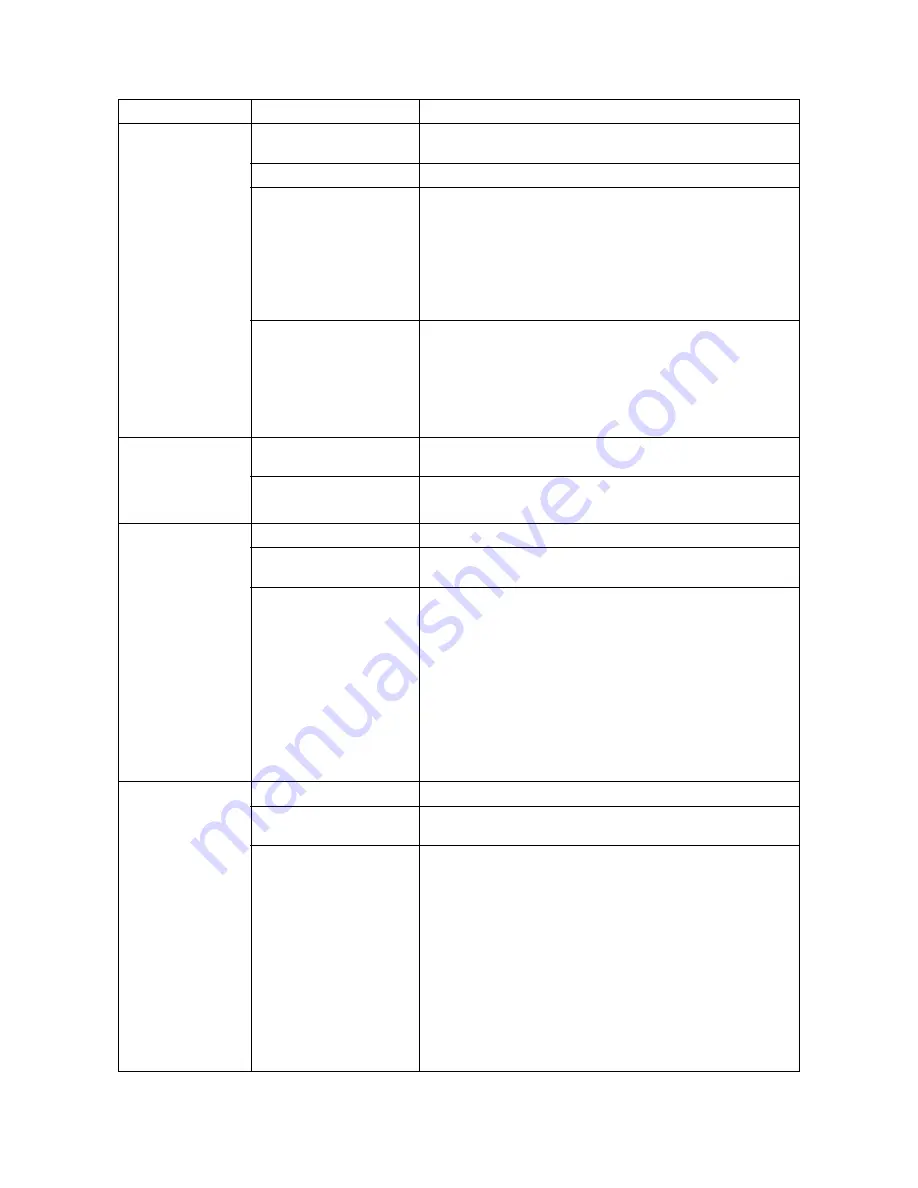

2K5

1-4-42

(5)

The developing fan

motor, fuser fan

motor, eject fan

motor or paper con-

veying fan motor 1/2

does not operate.

1. Poor contact in the con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

2. Broken motor coil.

Check for continuity across the coil. If none, replace the motor.

3. Defective motor.

Run maintenance item U037 and check if the motor operates

when the following terminals on the PWB goes low. If not, replace

the corresponding motor.

Developing fan motor: YC2-6 on the engine PWB

Fuser fan motor: YC13-2 on the engine PWB

Eject fan motor: YC37-2 on the engine PWB

Paper conveying fan motor 1: YC8-B16 on the engine PWB

Paper conveying fan motor 2: YC8-B18 on the engine PWB

4. Defective engine PWB.

Run maintenance item U037 and check if following terminals on

the PWB goes low. If not, replace the engine PWB.

Developing fan motor: YC2-6 on the engine PWB

Fuser fan motor: YC13-2 on the engine PWB

Eject fan motor: YC37-2 on the engine PWB

Paper conveying fan motor 1: YC8-B16 on the engine PWB

Paper conveying fan motor 2: YC8-B18 on the engine PWB

(6)

The controller fan

motor or operation

fan motor does not

operate.

1. Poor contact in the con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

2. Broken motor coil.

Check for continuity across the coil. If none, replace the motor.

(7)

The paper feed

clutch 1/2, feed

clutch 1/2/3, MP

paper feed clutch,

MP feed clutch, reg-

istration clutch,

duplex feed clutch or

toner feed clutch

does not operate.

1. Broken clutch coil.

Check for continuity across the coil. If none, replace the clutch.

2. Poor contact in the con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

3. Defective engine PWB.

Run maintenance item U032 and check if following terminals on

the engine PWB goes low. If not, replace the engine PWB.

Paper feed clutch 1: YC8-A13 on the engine PWB

Paper feed clutch 2: YC8-A15 on the engine PWB

Feed clutch 1: YC8-B8 on the engine PWB

Feed clutch 2: YC8-A12 on the engine PWB

Feed clutch 3: YC8-A5 on the engine PWB

MP paper feed clutch: YC7-9 on the engine PWB

MP feed clutch: YC7-11 on the engine PWB

Registration clutch: YC8-B15 on the engine PWB

Duplex feed clutch: YC8-B9 on the engine PWB

Toner feed clutch: YC8-A17 on the engine PWB

(8)

The feedshift sole-

noid does not oper-

ate.

1. Broken solenoid coil.

Check for continuity across the coil. If none, replace the solenoid.

2. Poor contact in the con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

3. Defective engine PWB.

Run maintenance item U033 and check if the solenoid operates. If

not, replace the engine PWB.

Problem

Causes

Check procedures/corrective measures

Summary of Contents for TASKALFA 300I

Page 1: ...SERVICE MANUAL Published in February 2010 842K5111 2K5SM061 Rev 1 TASKalfa 300i ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2K5 This page is intentionally left blank ...

Page 22: ...2K5 1 1 8 This page is intentionally left blank ...

Page 196: ...2K5 1 4 52 This page is intentionally left blank ...

Page 252: ...2K5 1 5 56 This page is intentionally left blank ...

Page 274: ...2K5 2 1 20 This page is intentionally left blank ...

Page 310: ...2K5 2 3 28 This page is intentionally left blank ...

Page 347: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 369: ...INSTALLATION GUIDE FOR BUILT IN FINISHER ...

Page 381: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Page 391: ...INSTALLATION GUIDE FOR FAX System ...

Page 407: ......

Page 408: ......