Preo

pe

ra

tio

na

l ch

eck

s/P

re-

driv

e ch

eck

s

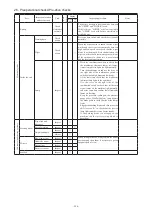

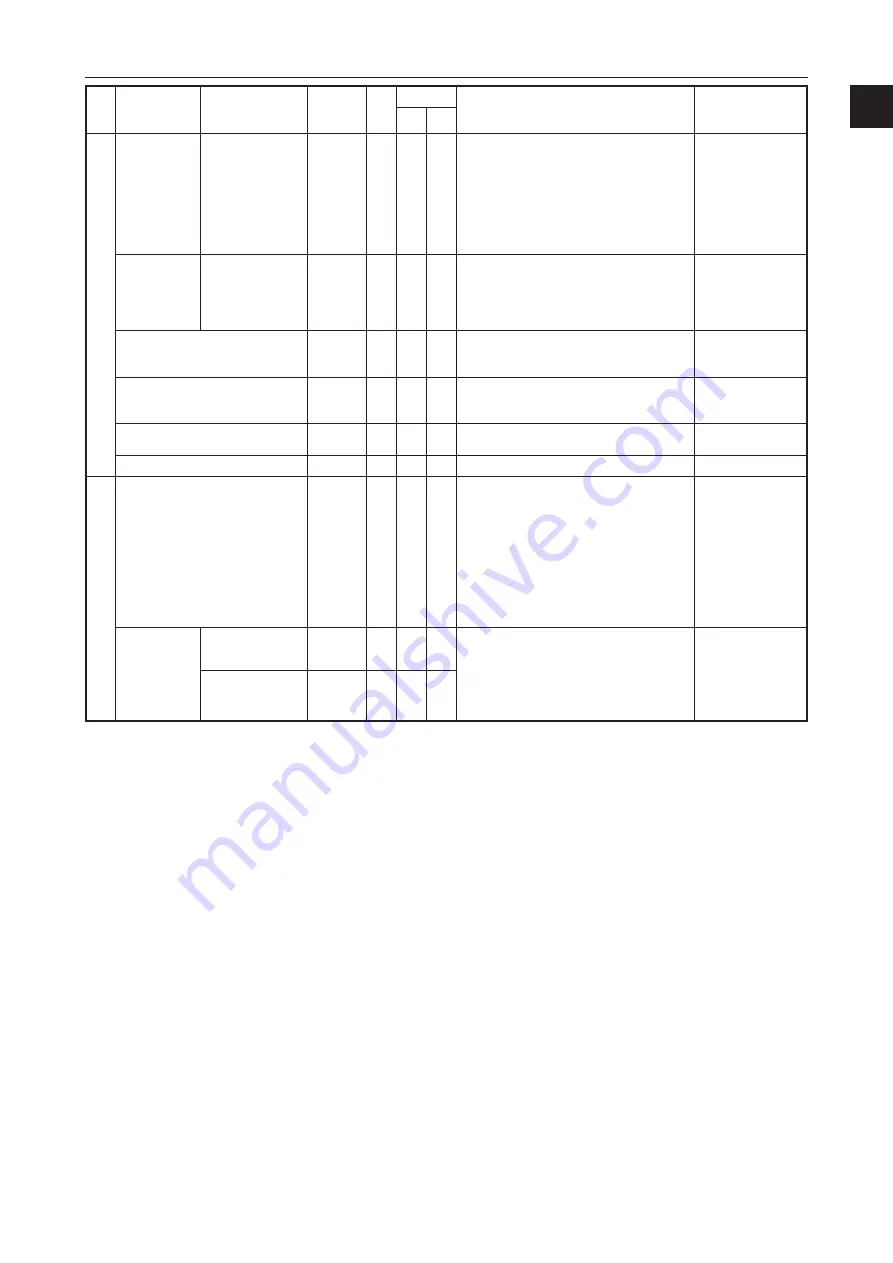

26. Preoperational checks/Pre-drive checks

- 297 -

Part

Inspection location

and service task

Task

W

he

n

de

fec

tiv

e

Engine

Inspection procedure

Notes

Before

start

After

start

Ca

b-

co

nt

ro

l a

nd

ste

er

ing

sy

ste

m

s

Shift lever

Gear change

Inspect

○

Check the gear status at each shift lever position.

D: Shifts automatically between 4 gears - 1st,

2nd, 3rd, and 4th

1: Only 1st gear

2: Two gears - 1st or 2nd

3: Three gears - 1st, 2nd, or 3rd

R: Moves the machine backwards (1 high gear -

2nd, and 1 low gear - 1st)

Control lever

and pedal

Actions, play, force

for operation

Inspect

○

Check that all the levers and pedals are in their

neutral positions when the engine is off.

If any lever or pedal is not in the neutral position

but rather hangs at an angle, adjust it before you

start work.

Information display

Check

action

○

Check whether the initial screen appears after

the initial start screen is displayed on the

information display.

Cluster meter panel

Inspect

○

Check that the indicator lamps do not indicate

any problem. If there is any problem, you must

stop the engine and investigate the cause.

Entry key system

Check

action

○

Touch the IC tag to check whether the engine

can be started.

Action of the door and cover locks

Inspect

○

Cr

ane

saf

et

y

devi

ce

s

ACS

Inspect

○

The ACS automatically switches to the "working

status setting screen" when the engine has started

and the PTO switch is switched on.

If any problem is indicated while the "working

status setting mode screen" is displayed,

investigate the cause of the problem before you

start work.

You must also make a "preoperational check" as

described in the separate instruction manual for

the ACS.

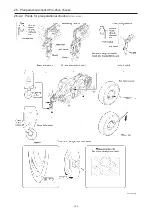

Overhoisting

detector

Buzzer

Inspect

○

Lift the weight of the overhoisting detector and

check that the warning buzzer in the cab sounds

and the crane stops automatically.

At the same time, check the condition of the

chain of the overhoisting detector weight and the

cord reel.

Automatic stop

Inspect

○

(T218151-072-0E)

Summary of Contents for PREMIUM CITYRANGE CR-200RF

Page 2: ...218711 背厚 14 5 mm 中 ...

Page 14: ... 12 4 Dimensions T217591 021 0E Specification of CR 200Rf ...

Page 16: ... 14 MEMO ...

Page 24: ... 22 MEMO ...

Page 30: ... 4 MEMO ...

Page 36: ... 10 MEMO ...

Page 38: ... 12 3 General operation devices 2 Outside the cab ...

Page 60: ... 34 MEMO ...

Page 74: ... 48 MEMO ...

Page 82: ... 56 7 Air conditioner 7 6 Display when errors are detected T217921 020 0E ...

Page 120: ... 94 MEMO ...

Page 129: ... 102 MEMO ...

Page 138: ... 111 17 Drive operation devices Drive operation devices ...

Page 139: ... 112 17 Drive operation devices ...

Page 153: ... 126 17 Drive operation devices ...

Page 154: ... 127 17 Drive operation devices Drive operation devices ...

Page 237: ... 208 21 Crane operation devices 21 Crane operation devices 061A 0005 0E 1 Inside the cab ...

Page 238: ... 209 21 Crane operation devices Crane operation devices ...

Page 239: ... 210 21 Crane operation devices 2 Outside the cab ...

Page 259: ... 230 22 Crane operation when the outriggers are used ON OFF ...

Page 299: ... 270 24 Crane operation NOTE Extension retraction sequence for each boom length ...

Page 320: ...26 Preoperational checks Pre drive checks 290 ...

Page 321: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 291 ...

Page 322: ...26 Preoperational checks Pre drive checks 292 ...

Page 329: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 299 ...

Page 330: ...26 Preoperational checks Pre drive checks 300 ...

Page 331: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 301 ...

Page 332: ... 302 MEMO ...

Page 340: ... 310 MEMO ...

Page 342: ...899 92187110 ...