Preo

pe

ra

tio

na

l ch

eck

s/P

re-

driv

e ch

eck

s

26. Preoperational checks/Pre-drive checks

- 287 -

Inspection/servicing item

Daily

inspection

Inspection procedure

Notes

Inspection location

Inspection item

Before

start

After

start

Pr

im

e

mov

er

Main unit

Deceleration and

acceleration status

○

・

After starting the engine, depress the accelerator

pedal and check the following. If you notice anything

abnormal, stop the engine immediately and

investigate the cause.

・

Does the engine rise smoothly to high revolutions

when you depress the accelerator pedal ?

・

The accelerator doesn't rest before the engine reaches

high revolutions.

・

After the engine reaches high revolutions, take your

foot off the pedal to check whether the engine speed

declines smoothly.

Startability and abnormal

noises

○

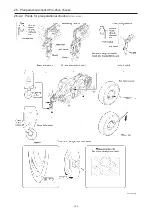

Lubrication system

Oil level

○

Check the engine oil when the machine is parked on the

level. Use the level gauge to check the level of the

engine oil and add more oil if the level is low. Change

the engine oil if it is extremely dirty.

Engine oil volume:

16L

Oil pan: 15L

Oil filter etc.: 1L

Fuel system

Inspect water separator

and remove water

○

Look at the level gauge on the water separator to check

how much moisture there is in the fuel.

Remove water

properly.

Cooling system

Loosening, tension status,

or damage of the fan belt

○

Excessive slack in the fan belt can cause overheating

and inadequate generation by the alternator. Excessive

tension can damage the engine bearings and snap the

fan belt. Check the tension of the fan belt and adjust it

if necessary.

Water level in radiator

and other parts of the

cooling system

○

Check the coolant level when the engine is sufficiently

cool. First, level the machine, then inspect the coolant

level through the inspection window on the side of the

reserve tank.

Make sure the coolant level is above the inspection

window for coolant level check. If the coolant level is

low, remove the cap from the top of the reserve tank

and add coolant.

Total coolant volume:

about 30L

Engine: 11.2L

Radiator: 7.2L

Sub-tank: 5.3L

Torque converter cooler:

2.5L

Piping: 4L

D

ev

ic

es

to

pr

ev

en

t d

iv

er

sio

n

of

sm

ok

e,

m

al

od

or

ous

g

as

,

an

d

ha

za

rd

ous

g

as

Device to prevent

diversion of carbon

monoxide and other

gases

Looseness of installation

and damages on exhaust

gas reduction devices

such as catalytic reactor

○

Check that the DEF electrothermal hose and cooling

water hose are connected securely and that there is no

crack, bending, or damage on them.

Check that the DEF

(AdBlue®) or cooling water is not

leaking from the DEF pump, DEF injector, DEF hose,

or cooling water hose.

Lamps and turn indicators

Lighting and flashing

status, dirt, or damage

○

・

Work the combination switch to check that the

headlamps, clearance lamps, tail lamps, license lamp,

meter lights etc. light normally.

・

Turn the headlamps on and use the lever on the right

side of the combination switch to switch between

high beam and low beam.

At the same time, check that the high beam indicator

lamp lights at the right time.

・

Use the lever on the left side of the combination

switch to check that all the turn signal lamps on the

machine light normally, and at the same time confirm

that all indicator lamps are flashing.

・

Keep the pressure reading on the pressure gauge

above 500kPa

(

5kgf/cm

2

) and depress the brake pedal

to check that the brake lamps light.

・

Engage the parking brake and then move the shift

lever to "R" to check that the reverse lamp lights and

the reverse buzzer sounds.

If the parking brake is not engaged, the machine

could start reversing which is hazardous.

Warning sound emitter,

windscreen wipers, windscreen

washer, defroster, and lock

system

Windscreen washer fluid

level and spraying status

○

Work the wiper switch to check that the wiper works

and that it switches normally between high and low

speed. Also check that the wiper blade is not damaged.

Press the button on the wiper switch to check that water

sprays well out of the spray nozzle, the nozzle is not

blocked and the reservoir is not empty.

Windscreen wiper wiping

status

○

Summary of Contents for PREMIUM CITYRANGE CR-200RF

Page 2: ...218711 背厚 14 5 mm 中 ...

Page 14: ... 12 4 Dimensions T217591 021 0E Specification of CR 200Rf ...

Page 16: ... 14 MEMO ...

Page 24: ... 22 MEMO ...

Page 30: ... 4 MEMO ...

Page 36: ... 10 MEMO ...

Page 38: ... 12 3 General operation devices 2 Outside the cab ...

Page 60: ... 34 MEMO ...

Page 74: ... 48 MEMO ...

Page 82: ... 56 7 Air conditioner 7 6 Display when errors are detected T217921 020 0E ...

Page 120: ... 94 MEMO ...

Page 129: ... 102 MEMO ...

Page 138: ... 111 17 Drive operation devices Drive operation devices ...

Page 139: ... 112 17 Drive operation devices ...

Page 153: ... 126 17 Drive operation devices ...

Page 154: ... 127 17 Drive operation devices Drive operation devices ...

Page 237: ... 208 21 Crane operation devices 21 Crane operation devices 061A 0005 0E 1 Inside the cab ...

Page 238: ... 209 21 Crane operation devices Crane operation devices ...

Page 239: ... 210 21 Crane operation devices 2 Outside the cab ...

Page 259: ... 230 22 Crane operation when the outriggers are used ON OFF ...

Page 299: ... 270 24 Crane operation NOTE Extension retraction sequence for each boom length ...

Page 320: ...26 Preoperational checks Pre drive checks 290 ...

Page 321: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 291 ...

Page 322: ...26 Preoperational checks Pre drive checks 292 ...

Page 329: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 299 ...

Page 330: ...26 Preoperational checks Pre drive checks 300 ...

Page 331: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 301 ...

Page 332: ... 302 MEMO ...

Page 340: ... 310 MEMO ...

Page 342: ...899 92187110 ...