- 277 -

Cr

ane

op

er

ation

24. Crane operation

3)

Watch the safety level bar graph to confirm safety as the independent controls are used to carefully slew the

crane to the desire position. However, if there is a risk of becoming overloaded or entering the slew-restricted

region, stop slewing there to avoid the danger.

Only use the ACS emergency switch in emergency situations, such as when the "slewing stop

system" malfunctions and does not allow slewing within the rated load range or slewing within

the permitted slewing region. Furthermore, even in such situations, slew very cautiously, making

sure to continuously monitor the safety level bar graph and ACS display for restricted slewing

regions to confirm safety.

(511A-1131-0E)

Always obtain permission from the site safety manager before turning the ACS emergency

switch to "release" for slewing in an emergency. Furthermore, contact your authorised KATO

dealer to request repair.

(511A-1132-0E)

NOTE

Even if the ACS emergency switch is turned to "release", the ACS will continue to emit the voice warnings "Caution

when slewing", "Danger maximum lifting capacity", "Slewing limit reached", and "Danger overload", chime

warnings, and emergency two-tone beep warnings

(

assuming the ACS is functioning normally

).

NOTE

If the ACS emergency switch is used to release the "slewing stop system," inertial slewing drift is controlled

based on the "slewing free/lock switch" position, located on the side panel.

(2) If slewing does not stop when overloaded

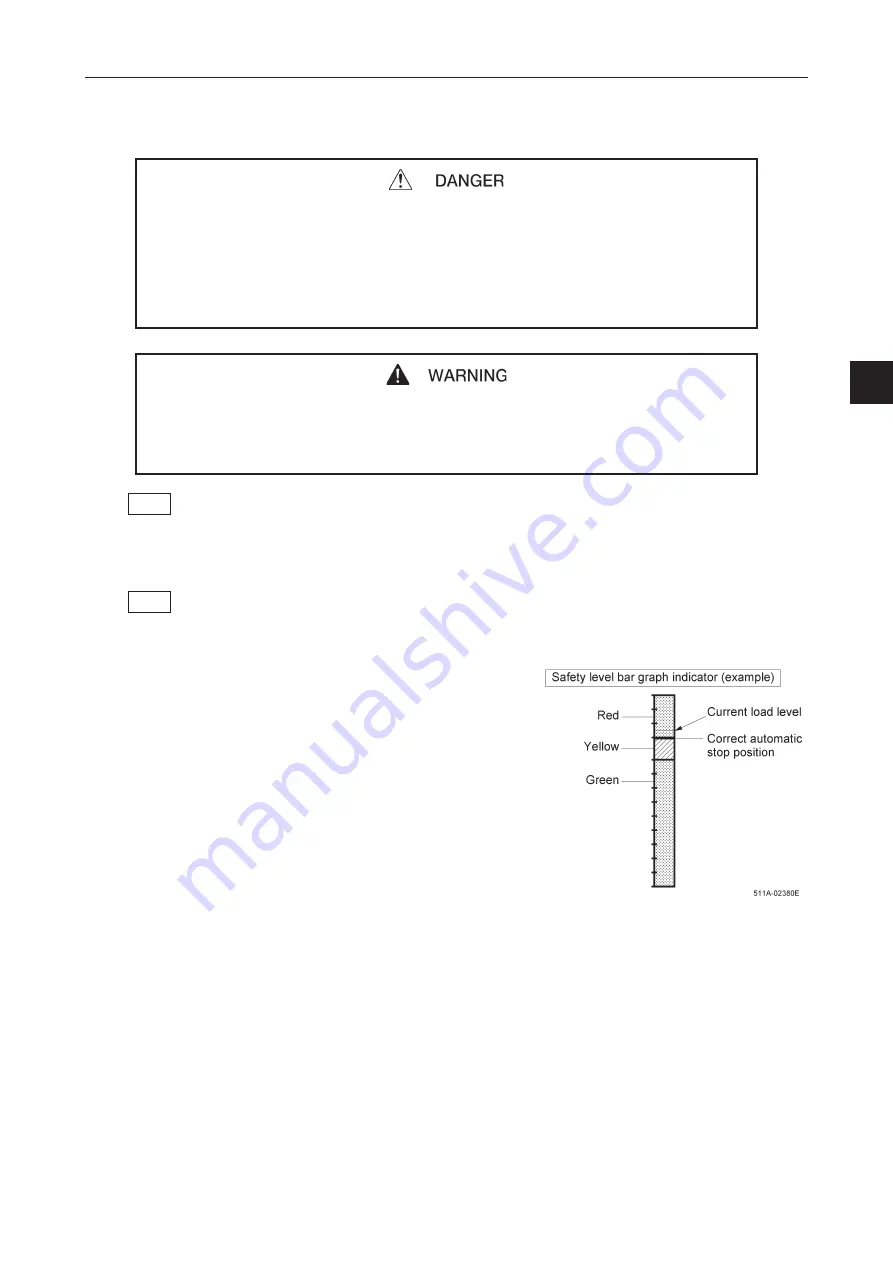

If the crane is level and yet slewing does not automatically

decelerate when the safety level bar graph approaches the yellow

zone and does not stop even after reaching the red zone, use the

following procedure to operate the crane and avoid danger.

1)

If slewing does not automatically decelerate when the safety

level bar graph approaches the yellow zone, move the slewing

control lever to the neutral position, while keeping a close watch

on the load movement, and let the engine idle.

2)

If slewing doe not decelerate adequately and appears as though the safety level bar graph indicator will not stop

within the yellow zone, forcibly stop the slewing motion by operating the lever in the opposite direction, being

careful not to let the load swing.

3)

If it is necessary to keep slewing in the same direction, keep slewing stopped and raise or retract the boom until

the safety level bar graph enters the green zone, then use the independent slewing controls to slowly and

cautiously slew the crane to the desired position, while carefully monitoring the safety level bar graph indicator.

Summary of Contents for PREMIUM CITYRANGE CR-200RF

Page 2: ...218711 背厚 14 5 mm 中 ...

Page 14: ... 12 4 Dimensions T217591 021 0E Specification of CR 200Rf ...

Page 16: ... 14 MEMO ...

Page 24: ... 22 MEMO ...

Page 30: ... 4 MEMO ...

Page 36: ... 10 MEMO ...

Page 38: ... 12 3 General operation devices 2 Outside the cab ...

Page 60: ... 34 MEMO ...

Page 74: ... 48 MEMO ...

Page 82: ... 56 7 Air conditioner 7 6 Display when errors are detected T217921 020 0E ...

Page 120: ... 94 MEMO ...

Page 129: ... 102 MEMO ...

Page 138: ... 111 17 Drive operation devices Drive operation devices ...

Page 139: ... 112 17 Drive operation devices ...

Page 153: ... 126 17 Drive operation devices ...

Page 154: ... 127 17 Drive operation devices Drive operation devices ...

Page 237: ... 208 21 Crane operation devices 21 Crane operation devices 061A 0005 0E 1 Inside the cab ...

Page 238: ... 209 21 Crane operation devices Crane operation devices ...

Page 239: ... 210 21 Crane operation devices 2 Outside the cab ...

Page 259: ... 230 22 Crane operation when the outriggers are used ON OFF ...

Page 299: ... 270 24 Crane operation NOTE Extension retraction sequence for each boom length ...

Page 320: ...26 Preoperational checks Pre drive checks 290 ...

Page 321: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 291 ...

Page 322: ...26 Preoperational checks Pre drive checks 292 ...

Page 329: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 299 ...

Page 330: ...26 Preoperational checks Pre drive checks 300 ...

Page 331: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 301 ...

Page 332: ... 302 MEMO ...

Page 340: ... 310 MEMO ...

Page 342: ...899 92187110 ...