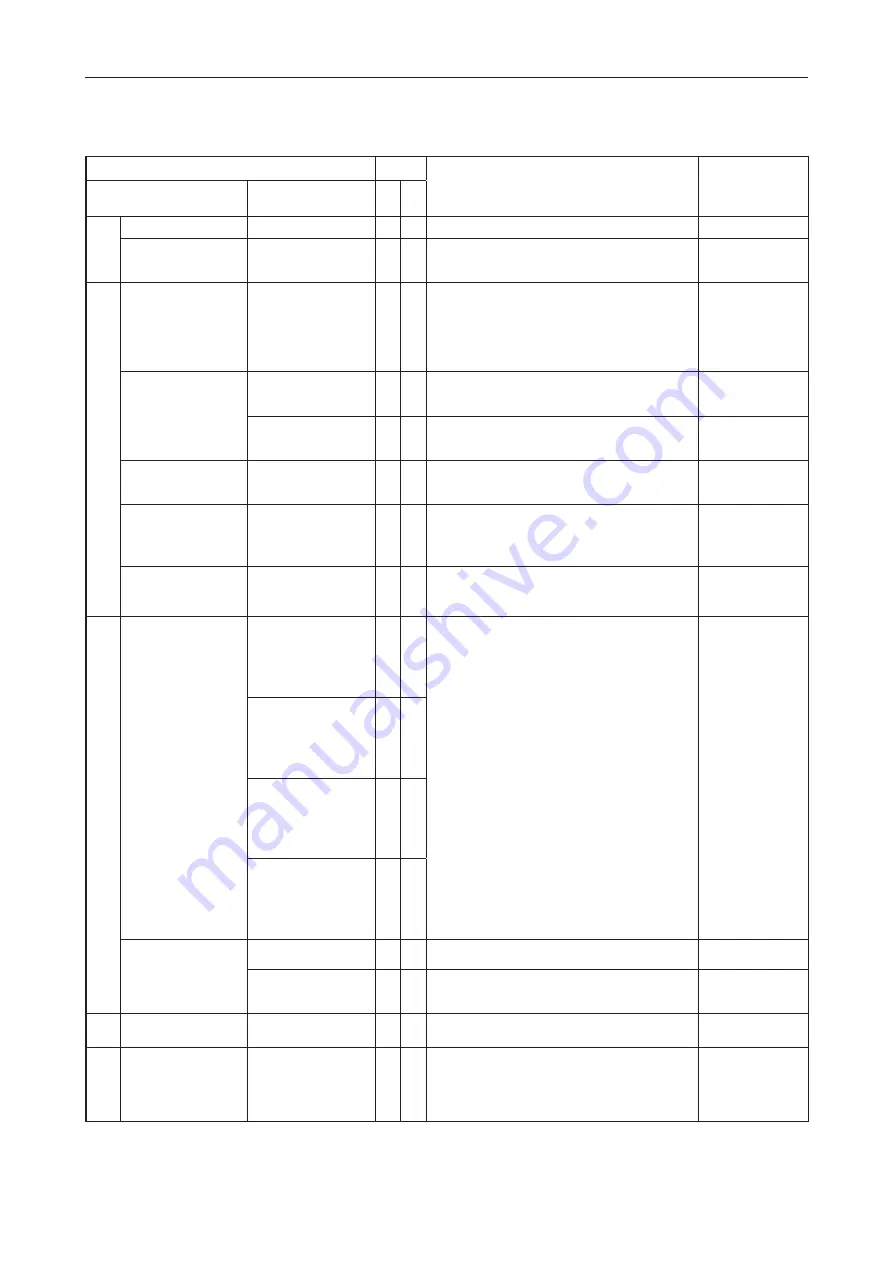

26. Preoperational checks/Pre-drive checks

- 286 -

26-1 Pre-drive checks

(511A-0073-0E)

26-1-1 Pre-drive check sheet

(511A-0074-0E)

Inspection/servicing item

Daily

inspection

Inspection procedure

Notes

Inspection location

Inspection item

Before

start

After

start

Ste

er

ing

sy

stem

Steering wheel

Steerability

○

Others

Lubrication using

autogreaster and grease

quantity

○

Machine equipped

with autogreaster

Br

ak

in

g

sy

stem

Air pressure gauge

Air pressure increase

○

The needle should normally be pointing between 5 and

9.

If the air pressure is 5 or below, check that it climbs

back to the 5

―

9 range when the engine is running.

If the air pressure climbs above 9, stop the engine

immediately and contact your authorised KATO dealer.

Brake pedal

Pedal stroke length

○

Excluding machines

equipped with air

brakes

Braking effect

○

Test the foot brake while the machine is moving very

slowly to check that the braking force is adequate and

applied evenly.

Parking brake

Lever stroke length

○

Check the function of

the parking brake

switch.

Reserve tank

Brake fluid level

○

Check that the fluid level is between the level marks

(LEVEL and MIN)

. If the fluid level is lowered in spite

of no external leakage, inspect wear of the disk brake

pads. If there is no abnormality, refill the brake fluid.

Brake valve, quick

release valve, and relay

valve

Sound of brake valve

exhaust

○

Dr

ive

sy

ste

m

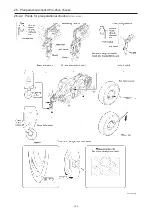

Tires

Air pressure

○

・

Check the tire pressure with a tire gauge while the

tires are still cool before driving anywhere. Adjust the

pressure as necessary to the rated pressure. Do not

stand in front of the tire during adjustment because

the tire may burst.

・

Check that there is no damage to the sidewalls and

no cracks or abnormal wear to the treads. Replace

any tires which have exposed canvas, regardless of

their age.

・

Check whether the treads are worn to the limit of

use. Also check for metal fragments, nails, stones

and other foreign bodies stuck into the treads or

caught in the tread grooves.

・

Check the depth of the tread grooves and look for

abnormal wear. Worn tires are dangerous as they

could burst or allow skidding.

・

Replace any tires where the limit of wear indicator is

visible.

・

There are six points at a depth of 1.6mm spaced

around the circumference of the tire which serve to

indicate when the limit of wear has been reached.

Air pressure: 900kPa

(

9.00kgf/cm

2

)

Tire size:

325/95R24

162/160K

Crack and damage

○

Abnormal wear

○

Tread groove depth

○

Wheels

Attachment status of disk

wheels

○

Loosening of wheel nuts

or bolts

○

Check that none of the wheel nuts is loose.

If any are loose, tighten them immediately to the

regulation torque.

Tightening torque:

600

―

650N

・

m

(61

―

66kgf

・

m)

Su

spe

n-

sio

n

Hydraulic suspension

Leveling and other

functionality

○

El

ec

tri

ca

l

sy

stem Battery

Battery fluid level

○

The battery electrolyte level should be between the

"UPPER" and "LOWER" levels.

If the level is at "LOWER" or below, top it up to the

"UPPER" level with battery electrolyte or distilled

water.

Summary of Contents for PREMIUM CITYRANGE CR-200RF

Page 2: ...218711 背厚 14 5 mm 中 ...

Page 14: ... 12 4 Dimensions T217591 021 0E Specification of CR 200Rf ...

Page 16: ... 14 MEMO ...

Page 24: ... 22 MEMO ...

Page 30: ... 4 MEMO ...

Page 36: ... 10 MEMO ...

Page 38: ... 12 3 General operation devices 2 Outside the cab ...

Page 60: ... 34 MEMO ...

Page 74: ... 48 MEMO ...

Page 82: ... 56 7 Air conditioner 7 6 Display when errors are detected T217921 020 0E ...

Page 120: ... 94 MEMO ...

Page 129: ... 102 MEMO ...

Page 138: ... 111 17 Drive operation devices Drive operation devices ...

Page 139: ... 112 17 Drive operation devices ...

Page 153: ... 126 17 Drive operation devices ...

Page 154: ... 127 17 Drive operation devices Drive operation devices ...

Page 237: ... 208 21 Crane operation devices 21 Crane operation devices 061A 0005 0E 1 Inside the cab ...

Page 238: ... 209 21 Crane operation devices Crane operation devices ...

Page 239: ... 210 21 Crane operation devices 2 Outside the cab ...

Page 259: ... 230 22 Crane operation when the outriggers are used ON OFF ...

Page 299: ... 270 24 Crane operation NOTE Extension retraction sequence for each boom length ...

Page 320: ...26 Preoperational checks Pre drive checks 290 ...

Page 321: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 291 ...

Page 322: ...26 Preoperational checks Pre drive checks 292 ...

Page 329: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 299 ...

Page 330: ...26 Preoperational checks Pre drive checks 300 ...

Page 331: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 301 ...

Page 332: ... 302 MEMO ...

Page 340: ... 310 MEMO ...

Page 342: ...899 92187110 ...