26. Preoperational checks/Pre-drive checks

- 294 -

Part

Inspection location

and service task

Task

W

he

n

de

fec

tiv

e

Engine

Inspection procedure

Notes

Before

start

After

start

En

gin

e-

re

la

te

d

A

cc

el

er

ato

r

Pedal slack and play

Inspect

○

・

After starting the engine, depress the

accelerator pedal and check the following. If

you notice anything abnormal, stop the engine

immediately and investigate the cause.

・

Does the engine rise smoothly to high

revolutions when you depress the accelerator

pedal ?

・

The accelerator doesn't rest before the engine

reaches high revolutions.

・

After the engine reaches high revolutions,

take your foot off the pedal to check whether

the engine speed declines smoothly.

Acceleration and deceleration

in response to pedal movement

Inspect

○

H

yd

ra

ul

ic

sy

ste

m

-re

la

te

d

Oil reservoir

Hydraulic oil

Check oil

level

○

Park the machine on the level ground in the

driving position and check the oil level from the

level gauge on the side of the oil reservoir.

The oil level changes with oil temperature, so

always check the oil level before you start the

engine.

With reference to the ambient air temperature,

check that the oil level is within the scale and

add more oil if the level is too low.

Reservoir capacity:

280L

Oil to use:

ISO viscosity grade 46

or equivalent

Cylinder

Oil leakage

Inspect

○

Responsivity

Inspect

○

Hydraulic pump

Oil leakage

Inspect

○

Abnormal noise

Inspect

○

Oil cooler

Oil leakage

Inspect

○

Rotary seal

Oil leakage

Inspect

○

Hydraulic valve

Oil leakage

Inspect

○

Sle

w

in

g-

rel

at

ed

Slew

ing

gea

r

Bearing

Abnormal noise on

slewing

Inspect

○

Slewing brake action

Inspect

○

Move the slewing brake switch to the "brake"

side then check that the slewing upper structure

does not slew even when you work the slewing

control.

W

in

ch

-rel

at

ed

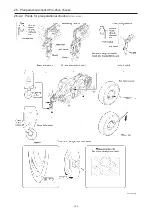

Hook

Attachment bolt

Inspect

○

Check the hook for play, abnormal wear, screw

deformation, damage to the wire rope retainer,

opening of the key etc.

Bearing play

Inspect

○

Sheave wear

Inspect

○

Wire rope retainer

Inspect

○

Hook

Inspect

○

Wire rope

Inspect

○

Before starting the day's work, check the state of

the locations through which the wire rope passes

to operate the crane.

Hook stowage confirmation switch

Inspect

○

・

If the boom is lowered, extended or the winch

is hoisted in the hook stowage mode, excessive

tension may be applied to the wire rope and

the rope may be broken. To prevent it, check

the operation of the hook stowage confirmation

switch according to the following procedure.

・

Fully retract the boom and make it horizontal.

・

Set ACS to the hook stowage mode.

・

Hoist the main hook to make the hook

stowage status.

・

Tilt the boom derricking/lowering lever in the

direction of lowering the boom and make sure

that the boom is not in motion.

Bo

om

-

rel

at

ed

Boom extension/retraction wire rope

Inspect

○

Boom slide plates (upper, lower)

Inspect

○

Summary of Contents for PREMIUM CITYRANGE CR-200RF

Page 2: ...218711 背厚 14 5 mm 中 ...

Page 14: ... 12 4 Dimensions T217591 021 0E Specification of CR 200Rf ...

Page 16: ... 14 MEMO ...

Page 24: ... 22 MEMO ...

Page 30: ... 4 MEMO ...

Page 36: ... 10 MEMO ...

Page 38: ... 12 3 General operation devices 2 Outside the cab ...

Page 60: ... 34 MEMO ...

Page 74: ... 48 MEMO ...

Page 82: ... 56 7 Air conditioner 7 6 Display when errors are detected T217921 020 0E ...

Page 120: ... 94 MEMO ...

Page 129: ... 102 MEMO ...

Page 138: ... 111 17 Drive operation devices Drive operation devices ...

Page 139: ... 112 17 Drive operation devices ...

Page 153: ... 126 17 Drive operation devices ...

Page 154: ... 127 17 Drive operation devices Drive operation devices ...

Page 237: ... 208 21 Crane operation devices 21 Crane operation devices 061A 0005 0E 1 Inside the cab ...

Page 238: ... 209 21 Crane operation devices Crane operation devices ...

Page 239: ... 210 21 Crane operation devices 2 Outside the cab ...

Page 259: ... 230 22 Crane operation when the outriggers are used ON OFF ...

Page 299: ... 270 24 Crane operation NOTE Extension retraction sequence for each boom length ...

Page 320: ...26 Preoperational checks Pre drive checks 290 ...

Page 321: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 291 ...

Page 322: ...26 Preoperational checks Pre drive checks 292 ...

Page 329: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 299 ...

Page 330: ...26 Preoperational checks Pre drive checks 300 ...

Page 331: ...Preoperational checks Pre drive checks 26 Preoperational checks Pre drive checks 301 ...

Page 332: ... 302 MEMO ...

Page 340: ... 310 MEMO ...

Page 342: ...899 92187110 ...