PROGRAMMING

INSTRUCTIONS

SINUS PENTA

189/452

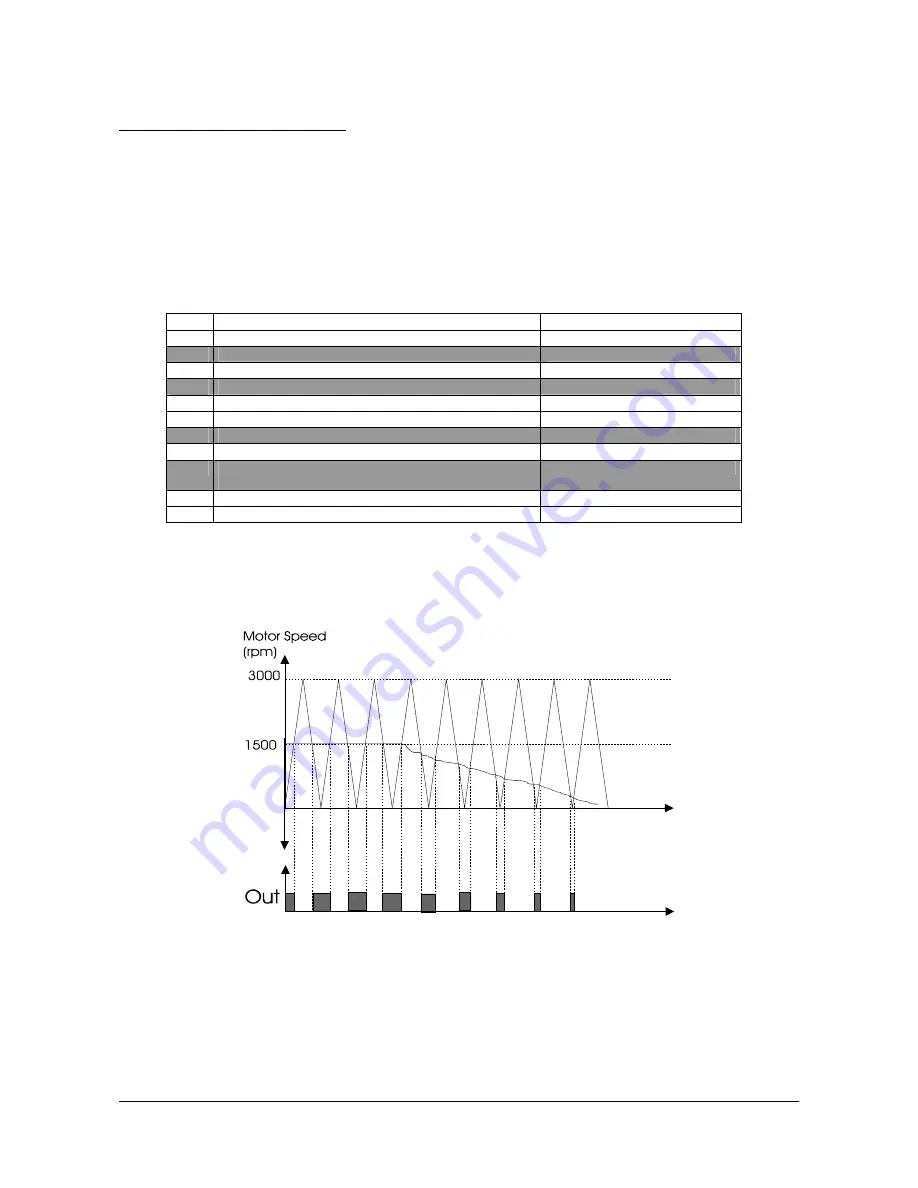

Example 5: Using the PWM Function.

Suppose that the motor of a machine tool is controlled by a drive. The tool must be lubricated based on the cutting

speed. At max. cutting speed, the electrovalve controlling lubrication must work for 0.5 sec with a frequency of 1Hz

(time period of 1 sec.): at max. speed, a duty cycle of 50% (Ton/T) is required, with a time period of 1 second; the time

when the electrovalve opens is directly proportional to the cutting speed.

Spd1 is the max. cutting speed and dtc1 is the duty cycle required; the saw carrier frequency required for PWM must

be 1 Hz (

P213

), the min. value must be 0rpm (when speed = 0rpm, the electrovalve is disabled) and max. value =

Spd1*100/ dtc1 = 2*Spd1.

Supposing that the tool can rotate in both directions, that Spd1 = 1500rpm and that the first digital output is used,

parameters are set as follows:

Table 47: MDO parameterization for the PWM function.

P270

MDO1: Digital output mode

PWM MODE

P271

MDO1: Variable A selection

A72: Speed Ref.

P272

MDO1: Variable B selection

P273

MDO1: Testing variable A

>

P274

MDO1: Testing variable B

P275

MDO1: Comparing value for Test A

3000.00 rpm

P276

MDO1: Comparing value for Test B

0.0 rpm

P277

MDO1: Function applied to the result of the two tests

P277a

MDO1: Variable C selection

D0: Disabled

P277b

MDO1: Function applied to the result of f(A,B) and C

test

P278

MDO1: Output logic level

TRUE

P215

Saw signal frequency

1Hz

Parameter

P215

in the ANALOG AND FREQUENCY OUTPUTS MENU sets the frequency of the saw wave, i.e. the

PWM frequency of the digital output.

In PWM mode, parameter

P275

sets the max. value (peak value) of the saw wave, while parameter

P276

sets the min.

value of the saw wave.

The test selected with

P273

is performed between the analog variable selected in

P271

and the saw wave.