Pump characteristics and data

l

V_g: Geometric displacement volume (

P 2851[0]

(ccm/rev))

l

eta_Vol,N: Volumetric efficiency at the pump’s rating point (

P 2851[4]

(%))

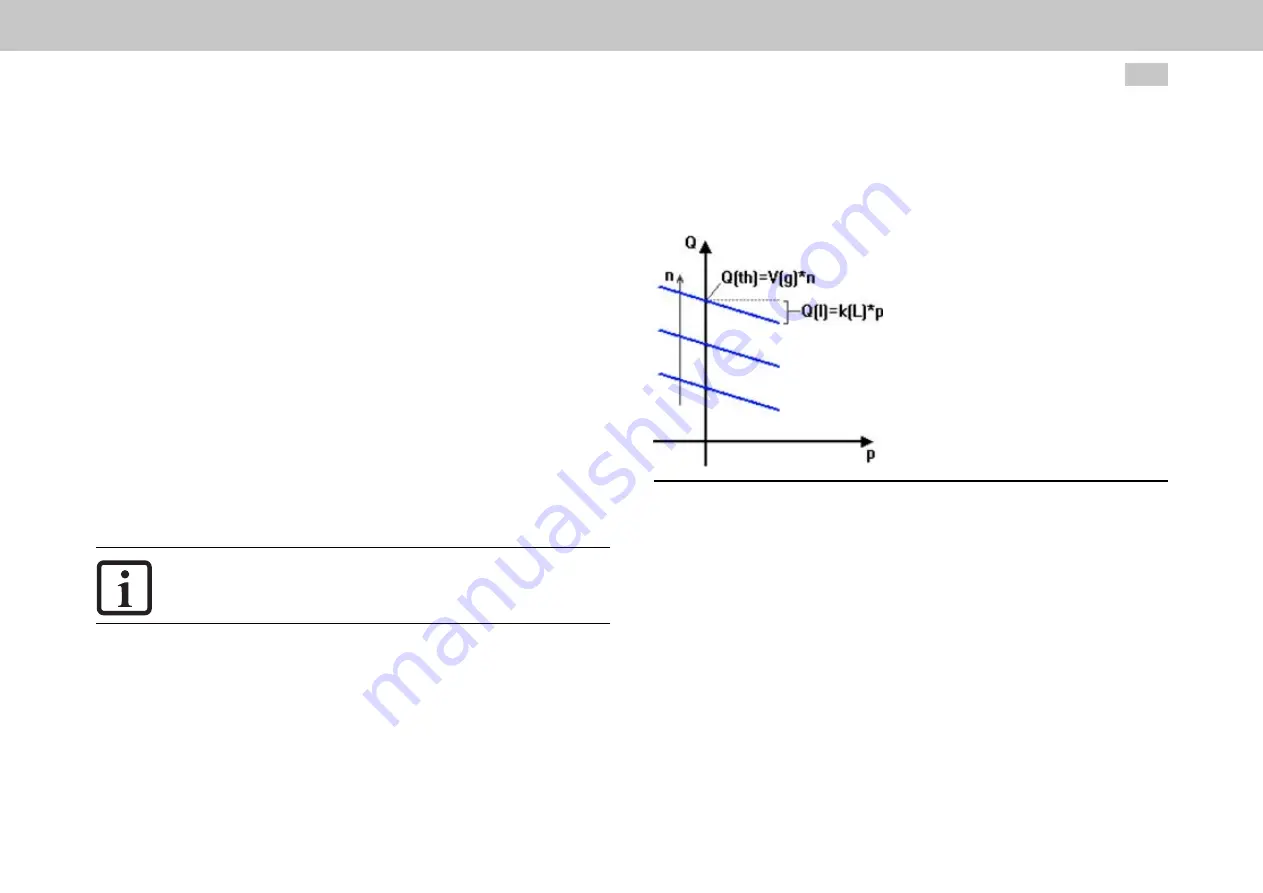

Theoretical volumetric flow rate Q_th is proportional to the speed:

l

Q_th = V_g ∙ n

Internal pump leakage volumetric flow rate Q_L must be subtracted from the actual

volumetric flow rate:

l

Q = Q_th - Q_L = V_g ∙ n - Q_L

It will typically be proportional to the pressure:

l

Q_L = p ∙ k_L(ϑ)

However, pump data sheets often do not specify the leakage volume rate constant,

but instead specify a “volumetric efficiency” ηvol,N for the pump’s rated point, in

which case:

l

Q_N = V_g ∙ n_N ∙ η_(vol,N)

l

Q_N [l/min] = V_g [cm³/rev] ∙ n_N [rev/min] ∙ eta_(Vol,N) [100 %]

NOTE

l

Make sure to convert to SI units!

Example

l

eta_(Vol,N) = 95 %, n_N = 1500 rev/min, v_G = 10 cm³/rev -> Q_N =

14,2 l/min

MOOG

ID No.: CB40859-001 Date: 11/2020

MSD Servo Drive - Device Help

175

7 Control

If you specify eta_(Vol,N), the servo drive will internally calculate k_L automatically

as follows:

l

k_L = V_g ∙ n_N ∙ (1 - eta_(Vol,N) ) ∙ p_N

Image 7.52: Pump characteristic curves

For the torque at the pump (= motor torque):

l

M = V_g / 2π ∙ p + (M_friction); (make sure to use SI units)

The friction torque is normally unknown and negligible (M_friction ~ 0). This means

that a “torque constant” c_M in [Nm/bar] can be calculated using the following

formula:

l

c_M [Nm/bar] = 1/(20pi) * V_g [cm^3/rev] = M [Nm] / p [bar]

Displacement volume V_g is usually specified in data sheets. In contrast, if there is a

pressure measurement available, the torque constant is easier to determine

experimentally if necessary. In this case, a constant pressure can be built up on the

drive in a steady state and the delivered motor torque can be used to calculate the

displacement volume.