MDS-E/EH Series Instruction Manual

8 Maintenance

426

IB-1501229-F

8.1 Periodic Inspections

8.1.1 Inspections

Periodic inspection of the following items is recommended.

[1] Are any of the screws on the terminal block loose? If loose, tighten them.

[2] Is any abnormal noise heard from the servo motor bearings or brake section?

[3] Are any of the cables damaged or cracked? If the cables move with the machine, periodically inspect the cables

according to the working conditions.

[4] Is the core of the load coupling shaft deviated?

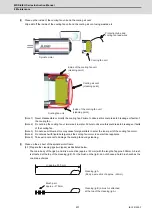

8.1.2 Cleaning of Spindle Motor

If you continue to use the spindle motor with dirt such as oil mist and dust adhered, its cooling performance degrades

and the motor is unable to fully exercise its performance, which may cause the spindle motor overheat alarm. In some

cases this may result in damage to the bearing or cooling fan. To ensure the cooling capability of the spindle motor's fan,

carry out periodical cleaning of the spindle motor and its cooling fan according to the following cleaning procedure.

Note that the spindle motor SJ-D Series and the spindle motor SJ-VL Series is used as an example in this procedure.

When cleaning the other spindle motors, carry it out based on this procedure.

WARNING

1. Before starting maintenance or inspections, turn the main circuit power and control power both OFF.

Wait at least fifteen minutes for the CHARGE lamp to turn OFF, and then using a tester, confirm that the input and output

voltage are zero. Failure to observe this could lead to electric shocks.

2. Inspections must be carried out by a qualified technician. Failure to observe this could lead to electric shocks. Contact

your nearest Mitsubishi branch or dealer for repairs and part replacement.

CAUTION

1. Never perform a megger test (measure the insulation resistance) of the drive unit.

Failure to observe this could lead to faults.

2. The user must never disassemble or modify this product.

CAUTION

Do not touch the motor for some time after turning OFF the power, as the motor remains at a high temperature.

This may lead to burns.

Содержание MDS-E

Страница 1: ......

Страница 3: ......

Страница 15: ......

Страница 17: ......

Страница 19: ......

Страница 21: ......

Страница 31: ......

Страница 32: ...1 IB 1501229 F 1 Installation ...

Страница 76: ...45 IB 1501229 F 2 Wiring and Connection ...

Страница 132: ...101 IB 1501229 F 3 Safety Function ...

Страница 142: ...111 IB 1501229 F 4 Setup ...

Страница 277: ...MDS E EH Series Instruction Manual 4 Setup 246 IB 1501229 F ...

Страница 278: ...247 IB 1501229 F 5 Servo Adjustment ...

Страница 351: ...MDS E EH Series Instruction Manual 5 Servo Adjustment 320 IB 1501229 F ...

Страница 352: ...321 IB 1501229 F 6 Spindle Adjustment ...

Страница 404: ...373 IB 1501229 F 7 Troubleshooting ...

Страница 455: ...MDS E EH Series Instruction Manual 7 Troubleshooting 424 IB 1501229 F ...

Страница 456: ...425 IB 1501229 F 8 Maintenance ...

Страница 475: ...MDS E EH Series Instruction Manual 8 Maintenance 444 IB 1501229 F ...

Страница 476: ...445 IB 1501229 F 9 Power Backup System ...

Страница 494: ...463 IB 1501229 F 10 Appx 1 Cable and Connector Assembly ...

Страница 504: ...473 IB 1501229 F 11 Appx 2 D A Output Specifications for Drive Unit ...

Страница 513: ...MDS E EH Series Instruction Manual 11 Appx 2 D A Output Specifications for Drive Unit 482 IB 1501229 F ...

Страница 514: ...483 IB 1501229 F 12 Appx 3 Protection Function ...

Страница 523: ...MDS E EH Series Instruction Manual 12 Appx 3 Protection Function 492 IB 1501229 F ...

Страница 524: ...493 IB 1501229 F 13 Appx 4 Compliance to EC Directives ...

Страница 528: ...497 IB 1501229 F 14 Appx 5 EMC Installation Guidelines ...

Страница 540: ...509 IB 1501229 F 15 Appx 6 Higher Harmonic Suppression Measure Guidelines ...

Страница 545: ...MDS E EH Series Instruction Manual 15 Appx 6 Higher Harmonic Suppression Measure Guidelines 514 IB 1501229 F ...

Страница 550: ......

Страница 554: ......