MDS-E/EH Series Instruction Manual

7 Troubleshooting

403

IB-1501229-F

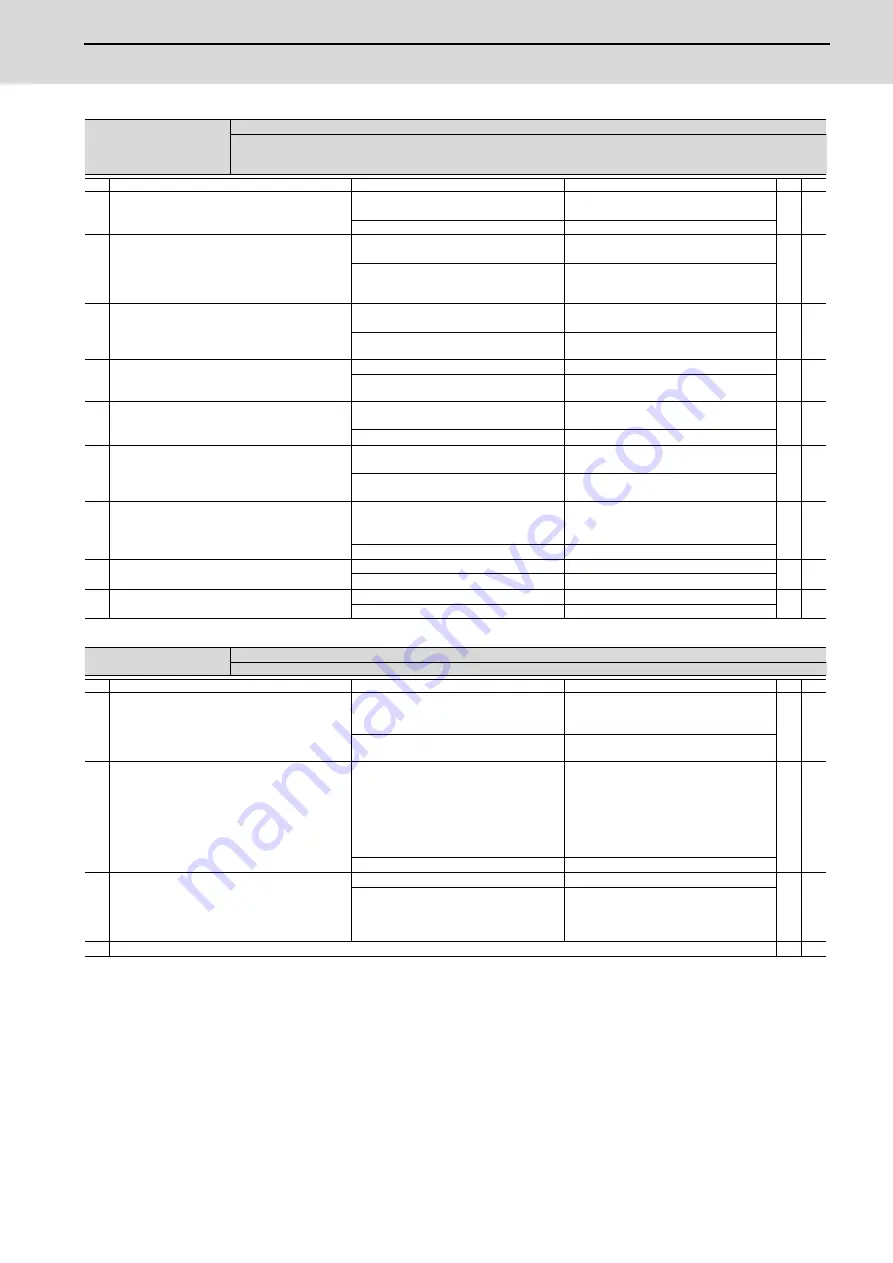

Alarm No.

51

Overload 2

Current command of more than 95% of the unit's max. current was being continuously given for longer than 1 second in a servo

system. In a spindle system, current command of more than 95% of the motor's max. current was being continuously given for

longer than 1 second.

Investigation details

Investigation results

Remedies

SV SP

1

Did the alarm occur immediately after READY ON?

The alarm occurred after ready ON before

operation starts.

Investigate item 2.

◯

The alarm occurred after normal operation.

Investigate item 5.

2

Check that the PN voltage is supplied to the drive

unit.

MDS-EJ/EJH Series is not connected to the power

supply unit, so investigate item 3 for MDS-EJ/EJH.

[1] Is the CHARGE lamp ON?

The CHARGE lamp becomes dark.

L+ or L- screw was loosened.

Increase the capacity of power supply.

Tighten the L+ and L- screws.

◯

Approx. 300V is correctly supplied.

Investigate item 3.

3

Check the motor power cable (U, V, W phases).

[1] The power cable is not connected.

[2] Is the cable connected to the motor for another

axis?

The connections are incorrect.

Connected to the incorrect axis.

Connect correctly.

◯

The connections are correct.

Investigate item 4.

4

Check the encoder cable connection.

[1] Is the cable connected to the motor for another

axis?

The connections are incorrect.

Connect correctly.

◯

The connections are correct.

Investigate item 5.

5

Check whether the machine has collided.

The machine has collided.

Check the machining program and soft limit

settings.

◯

The machine has not collided.

Investigate item 6.

6

Check whether the current value on the NC Servo

Monitor screen is saturated during acceleration/

deceleration.

The current is saturated during acceleration/

deceleration.

Increase the acceleration/ deceleration time

constant.

◯

The current value during acceleration/

deceleration is appropriate.

Investigate item 7.

7

Check the encoder Feedback.

The Feedback signal is abnormal.

- The droop does not stabilize.

Replace the encoder.

(With the absolute position system, the zero

point must be established.)

◯

The Feedback signal is normal.

Replace the drive unit.

8

Check the load meter value.

The value is large.

Lower the load.

◯

The value is normal.

Investigate item 9.

9

Check the PLG output waveform.

For TS5690, waveform cannot be checked.

There is a problem.

Adjust the PLG output waveform.

◯

Normal

Replace the drive unit.

Alarm No.

52

Excessive error 1

A difference between the actual and theoretical motor positions during servo ON exceeded the setting value.

Investigation details

Investigation results

Remedies

SV SP

1

The load inertia is large.

The unbalance torque in the Z (gravity) direction is

high.

An excessive workpiece or tool is mounted on the

spindle.

The load inertia is excessive.

[1] Lower the machine weight applied to the

servo motors (by the unbalance torque).

[2] Lower the weight of the workpiece.

◯

◯

The load inertia is normal.

Investigate item 2.

2

Check the excessive error detection width.

Servo

SV053

Spindle

SP023 (Interpolation, spindle

synchronization)SP053 (Non-interpolation)

The excessive error detection width is too

small.

Servo standard value:

SV053 ={RAPID/(60*PGN1)}/2

Spindle standard value:

No alarm is set at SP023 =120:0

SP053 =motor max. speed×6/PGV/2

Set appropriate values.

◯

◯

Appropriate values are set.

Investigate item 3.

3

Check the position encoder polarity.

SV017/bit4 (Servo)

SP017/bit4 (Spindle: position FB)

SP017/bit0 (Spindle: speed FB)

#3106/bit7 (Synchronous tap control)

The polarity is reversed.

Correctly set the parameters.

◯

◯

Normal.

Investigate item 4.

4

Check the alarm No. "51" items.

◯

◯

Содержание MDS-E

Страница 1: ......

Страница 3: ......

Страница 15: ......

Страница 17: ......

Страница 19: ......

Страница 21: ......

Страница 31: ......

Страница 32: ...1 IB 1501229 F 1 Installation ...

Страница 76: ...45 IB 1501229 F 2 Wiring and Connection ...

Страница 132: ...101 IB 1501229 F 3 Safety Function ...

Страница 142: ...111 IB 1501229 F 4 Setup ...

Страница 277: ...MDS E EH Series Instruction Manual 4 Setup 246 IB 1501229 F ...

Страница 278: ...247 IB 1501229 F 5 Servo Adjustment ...

Страница 351: ...MDS E EH Series Instruction Manual 5 Servo Adjustment 320 IB 1501229 F ...

Страница 352: ...321 IB 1501229 F 6 Spindle Adjustment ...

Страница 404: ...373 IB 1501229 F 7 Troubleshooting ...

Страница 455: ...MDS E EH Series Instruction Manual 7 Troubleshooting 424 IB 1501229 F ...

Страница 456: ...425 IB 1501229 F 8 Maintenance ...

Страница 475: ...MDS E EH Series Instruction Manual 8 Maintenance 444 IB 1501229 F ...

Страница 476: ...445 IB 1501229 F 9 Power Backup System ...

Страница 494: ...463 IB 1501229 F 10 Appx 1 Cable and Connector Assembly ...

Страница 504: ...473 IB 1501229 F 11 Appx 2 D A Output Specifications for Drive Unit ...

Страница 513: ...MDS E EH Series Instruction Manual 11 Appx 2 D A Output Specifications for Drive Unit 482 IB 1501229 F ...

Страница 514: ...483 IB 1501229 F 12 Appx 3 Protection Function ...

Страница 523: ...MDS E EH Series Instruction Manual 12 Appx 3 Protection Function 492 IB 1501229 F ...

Страница 524: ...493 IB 1501229 F 13 Appx 4 Compliance to EC Directives ...

Страница 528: ...497 IB 1501229 F 14 Appx 5 EMC Installation Guidelines ...

Страница 540: ...509 IB 1501229 F 15 Appx 6 Higher Harmonic Suppression Measure Guidelines ...

Страница 545: ...MDS E EH Series Instruction Manual 15 Appx 6 Higher Harmonic Suppression Measure Guidelines 514 IB 1501229 F ...

Страница 550: ......

Страница 554: ......