4-18

BE1-BPR Functional Description

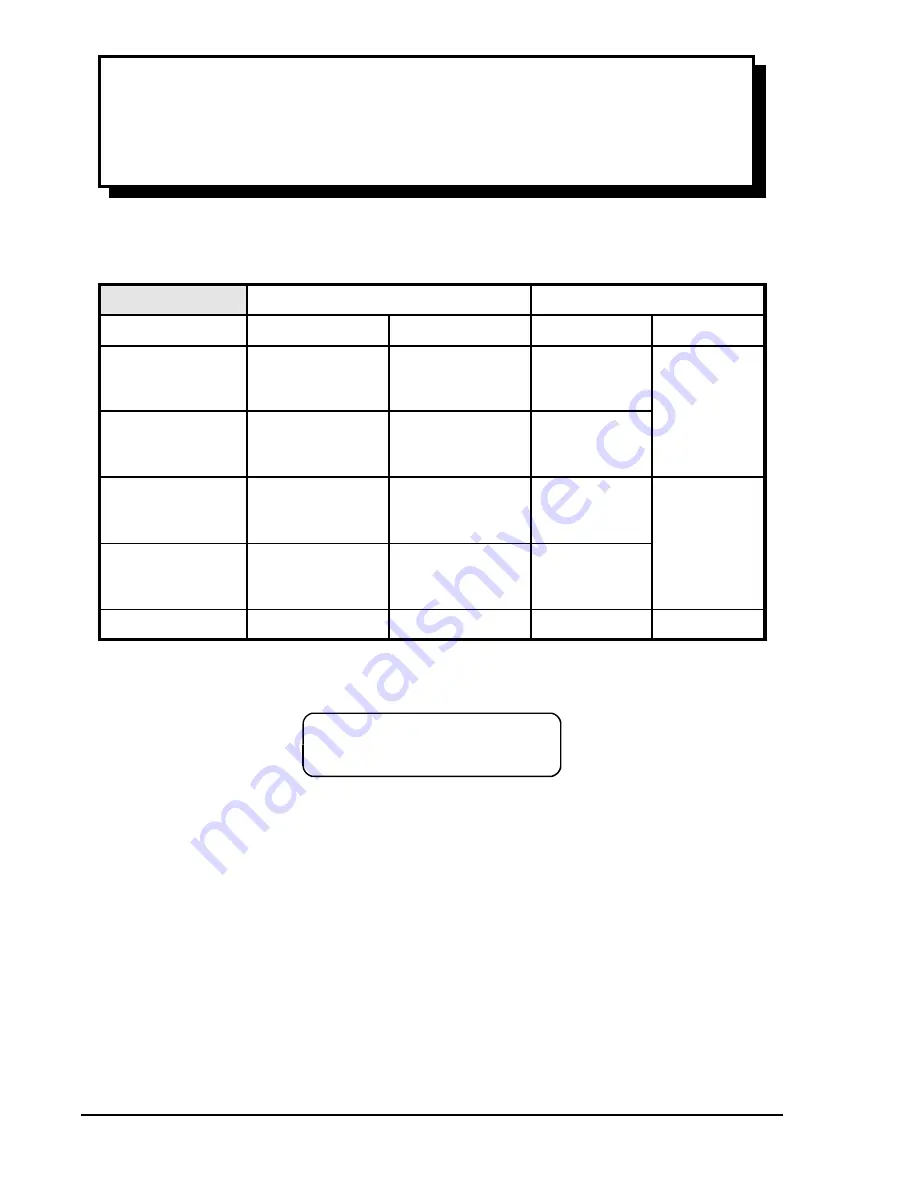

CAUTION

A pickup setting range check is made each time logic settings are changed that affect the fault

detector pickup settings. For example, if PU1=5.00 and LF1 setting is changed from PI,1 to PI,2,

the PU1 setting will automatically change from 5.00 to 1.00 (the maximum allowable setting for

a Type 2 fault detector on a 5 A unit). This kind of pickup setting adjustment can also occur if the

active relay logic is replaced with logic that has different LF settings.

38

38

38

The PU command sets the trip value of each fault detector and the moving average filter cycles for Type 2

fault detectors.

PU

Fault detector pickup levels

HMI Menu Branch: 1

Parameter

Unit of Measure

Range

Increment

Default

level

5 A CT

LFx=type,1 or 3

amperes

0.25 - 9.99

0.01

PU1=8.00

PU2=2.00

PU3=0.50,10

level

5 A CT

LFx=type,2

amperes

0.05 - 1.00

0.01

level

1 A CT

LFx=type,1 or 3

amperes

0.05 - 2.00

0.01

PU1=2.00

PU2=2.00

PU3=0.20,10

level

1 A CT

LFx=type,2

amperes

0.01 - 0.10

0.01

cycles

cycles

1 - 100

1

N/A

NOTE: Types 1 and 3 PU settings can be set below the stated minimum settings. However,

specified accuracies will not be maintained when PU settings are set outside the setting range.

PU HMI Screen Example

PU Command

Purpose:

Read or change fault detector pickup levels

Syntax:

PU[x] [=<level>[,<cycles>]]

Comments:

x = 1 (fault detector 1), 2 (fault detector 2), or 3 (fault detector 3)

level = pickup level in amperes for fault detector x

cycles = number of moving average filter cycles

Cycles parameter is used only if an analog channel is programmed to have a moving average

filter (Lfx=type,2). See LF command information in

BESTlogic Functions section. An access

area one or two password is required to change settings.

PU Command Examples

1.

Set the analog channel pickup level at 6.2 amperes.

PU1=6.2

2.

Read the pickup setting for all channels.

PU

PU1=6.2; PU2=0.5; PU3=0.1,10

Содержание BE1-BPR

Страница 1: ...Publication 9 2720 00 990 Revision E 12 98 INSTRUCTION MANUAL for BE1 BPR BREAKER PROTECTION RELAY...

Страница 31: ...BE1 BPR Application 2 17...

Страница 41: ...BE1 BPR Human Machine Interface 3 3 Figure 3 3 BE1 BPR Relay Horizontal Mount Front And Rear Views...

Страница 42: ...3 4 BE1 BPR Human Machine Interface Figure 3 4 BE1 BPR Relay Vertical Mount Front View...

Страница 43: ...BE1 BPR Human Machine Interface 3 5 Figure 3 5 BE1 BPR Relay Vertical Mount Rear View...

Страница 49: ...4 6 BE1 BPR Functional Description Figure 4 2 Enhanced BE1 BPR Menu Display Screens...

Страница 50: ...BE1 BPR Functional Description 4 7 Figure 4 3 Standard BE1 BPR Menu Display Screens...

Страница 94: ...5 4 BE1 BPR BESTlogic Figure 5 1 BESTlogic Function Blocks...

Страница 120: ...7 2 BE1 BPR Installation Figure 7 1 Overall Dimensions Figure 7 2 Cutout Dimensions Panel Mount...

Страница 121: ...BE1 BPR Installation 7 3 Figure 7 3 Overall Dimensions Vertical Mount...

Страница 122: ...7 4 BE1 BPR Installation Figure 7 4 Overall Dimensions Side View Vertical Mount...

Страница 123: ...BE1 BPR Installation 7 5 Figure 7 5 Panel Drilling Diagram Vertical Mount...