Operation

3-30 Operation

Thermo Fisher Scientific

REC 4132 Rev

E

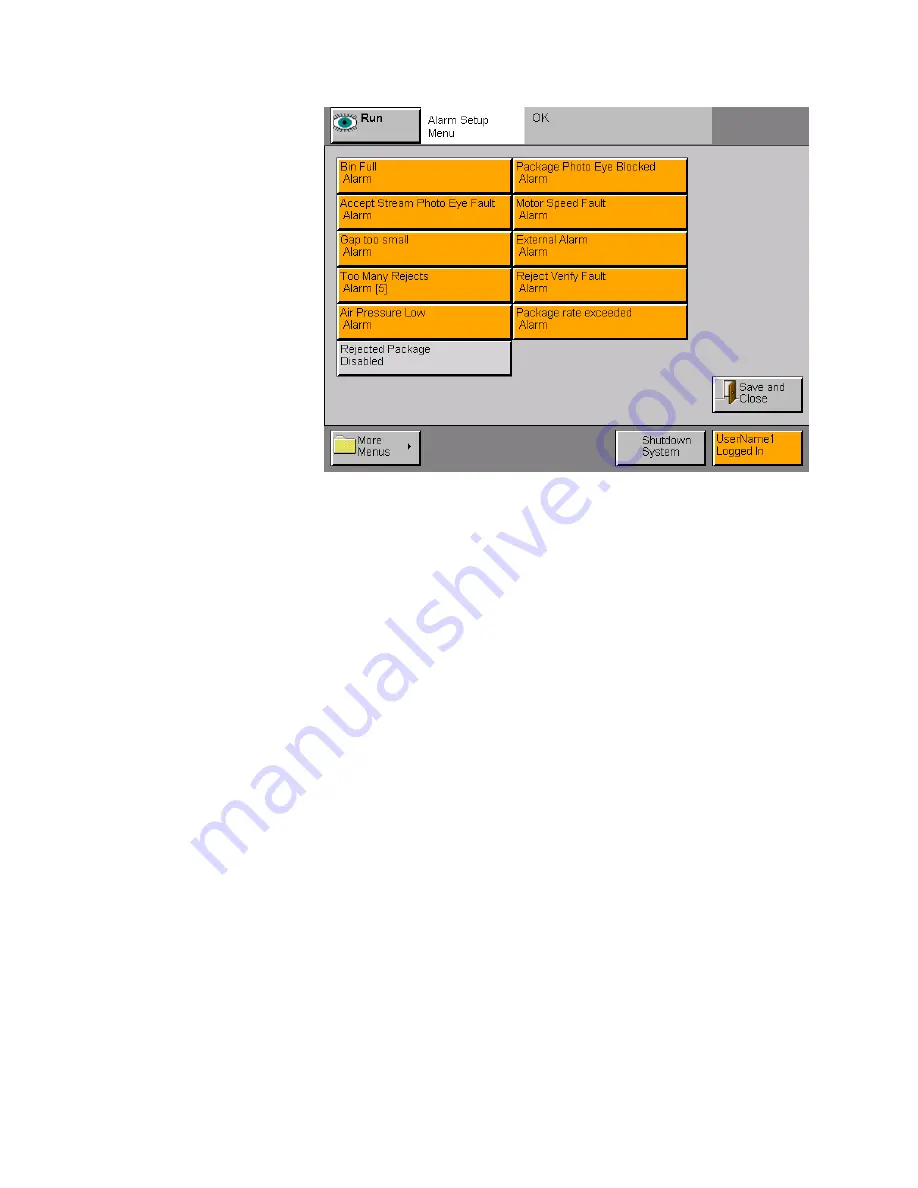

Alarm Setup Default

Figure 3–28.

User Configurable Alarms

•

Bin Full

– activated when the reject bin is full (requires photo eye)

•

Accept Stream Photo Eye Fault

– indicates a fault in the accept

stream (requires photo eye)

•

Gap too Small

– indicates the gap between packages is not large

enough (uses the internal photo eye). When Gap too Small is set to

warn it is self-clearing. The warning is cleared on the next good

package.

•

To Many Rejects

– indicates there have been to many consecutive

rejects. Determined in the

A

LARM

S

ETUP

menu. The default setting

is 5 and the rejects have to be consecutive.

•

Air Pressure Low

– indicates the air pressure to the reject device is

low (requires the installation of a pressure sensor)

•

Package Photo Eye Blocked

– indicates the photo eye on the

conveyor is blocked (uses the internal photo eye)

•

External Alarm

– response to an external alarm such as a flap

detector, product jam upstream etc.

•

Reject Verify Fault

– indicates the reject verify function is not

performing properly

•

Motor Speed Fault -

No speed pulses, the

EZx

conveyor is off, or an

incorrect count that indicates the speed is incorrect.

•

Rejected Package

– a contaminated package was rejected during

product inspection.

Summary of Contents for EZx

Page 1: ...EZx Contaminant Detector User Guide REC 4132 Rev E Part Number 062477...

Page 7: ......

Page 8: ......

Page 13: ...Contents Thermo Fisher Scientific Contents v REC 4132 Rev E This Page Left Blank Intentionally...

Page 14: ......

Page 112: ......

Page 214: ......

Page 228: ......

Page 231: ...This Page Left Blank Intentionally...

Page 232: ......

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......