1-20

1010BXFM-3

Section 1

All IBM compatible computers provide at least one serial port using either a 9-pin or 25-pin

D-type connector. The port designation can be either COM 1 or COM 2. Usually, when a com-

puter has two serial ports, COM 1 will be the 9-pin connector and COM 2 will be the 25-pin

connector. However, port designations can vary from manufacturer to manufacturer, so you

will have to positively identify the COM port you wish to use for the flow computer interface.

Connect cable between the flow computer and your PC using either the 25-pin or the 9-pin

connector, depending upon the architecture of the port.

NOTE: Be aware that on some laptop computers, the available COM ports may be

assigned to peripheral devices, such as a modem, mouse or an infrared port,

etc. Therefore, you may not have a COM port available for this interface. In

such a case, refer to your PC manual for instructions on how to reassign your

COM ports for standard operation.

The following example explains how to set up HyperTerminal™:

From the Windows 95/98™ desktop, Left-Click on the [START] button.

Holding down the left mouse button, move the highlight up to [Programs], then across to

[Accessories]. Slide the highlight down to [HyperTerminal], then release the left mouse

button.

Within the HyperTerminal™ window, move the mouse pointer down to [Hyperterm.exe]

and then double-click the left mouse button.

This selects the [Connection Description] dialog box. Enter a name for your connection

(e.g., 1010BX). You can optionally select an icon for this connection by clicking on one of

the icons displayed in the scrolling frame at the bottom of the window. Click [OK].

This selects the [Phone Number] dialog box. Move cursor to the arrow at right of [Connect

Using] field. Left click on arrow to expand field and move the highlight down to [Direct to

Com 1 (or 2)] depending on the port connected to the interface cable. Click [OK] to select

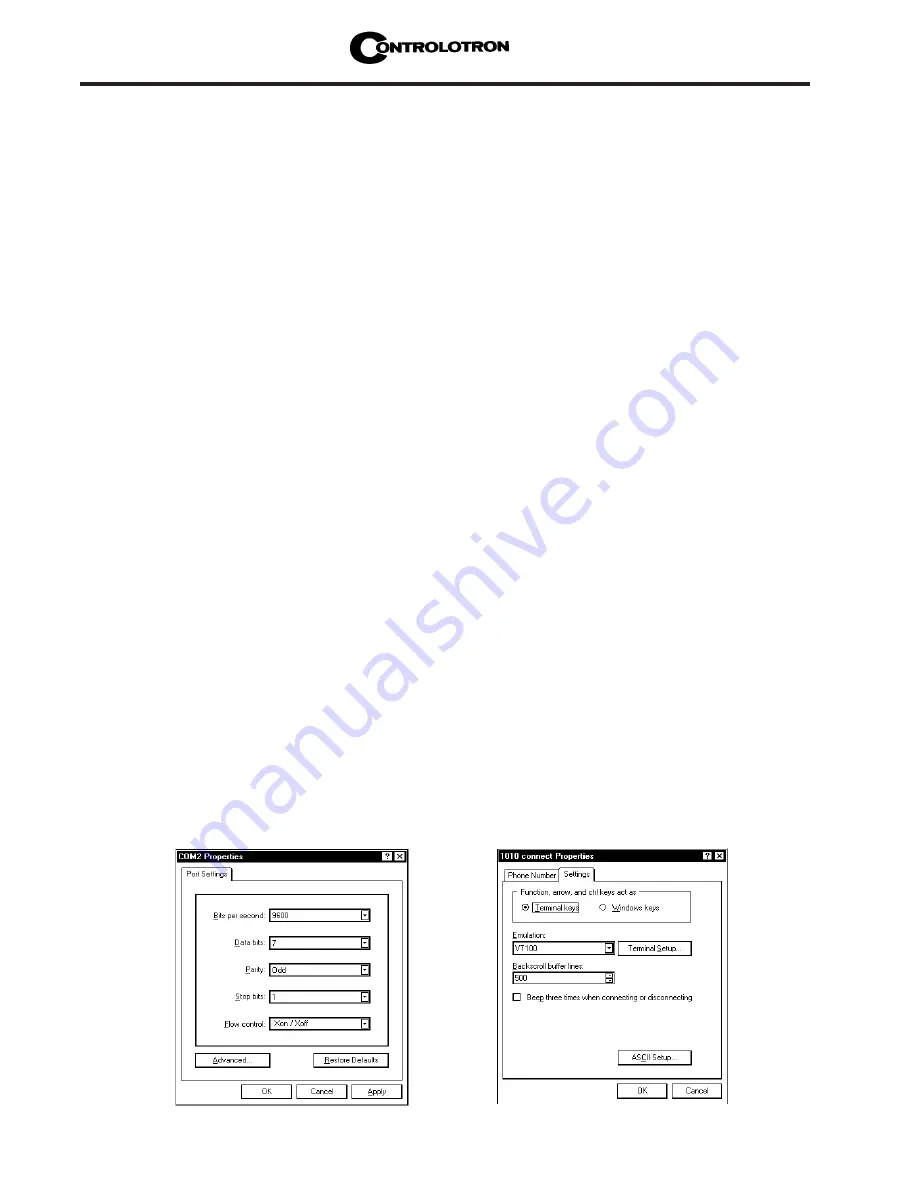

[Com 1 (or 2) Properties] Dialog box. Set up your RS-232 parameters as shown (below left).

Left-click on the [OK] button.

You will now see a blank terminal screen. Next click [File] on the top menu bar. Drag the

highlight down to [Properties] and then left-click.

Left-click [Settings] tab. Expand the [Emulation] box by clicking the <Down Arrow> on the

right-hand side. Drag the highlight down to [VT-100] and then left-click to select it as

shown (below right).

Summary of Contents for SITRANS FUH1010PVX

Page 2: ......

Page 6: ......

Page 14: ......

Page 28: ......

Page 130: ......

Page 186: ......

Page 187: ...Siemens Hardware ...

Page 188: ......

Page 189: ...Siemens Hardware ...

Page 190: ......

Page 191: ...Siemens Hardware ...

Page 192: ......

Page 193: ...Siemens Hardware ...

Page 194: ......

Page 195: ...Siemens Hardware ...

Page 196: ...1010N 5 7 INSTALLATION DRAWING ANALOG INPUT MODULE 21614 C ...

Page 201: ...1011HNS 8 TRANSDUCER PART NUMBER L H W SIZE C D SIZE A B 21614 C Siemens Hardware ...

Page 202: ......

Page 203: ...Siemens Hardware ...

Page 204: ......

Page 206: ......

Page 214: ......

Page 225: ...Siemens Hardware ...