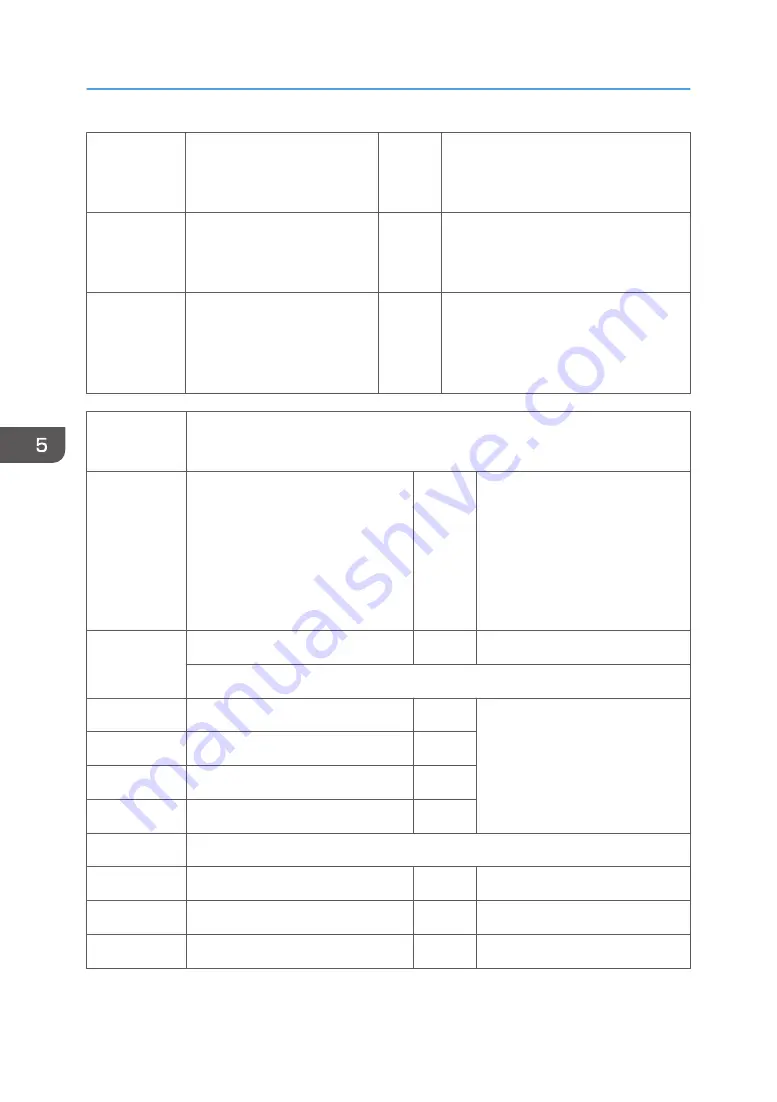

1-103-017 Ex.Idling Time(H)

*ENG

[ 0 to 60 / 0 / 1 sec/step]

Specifies the idling time in the high

temperature condition.

1-103-018 Ex.Idling Time(M)

*ENG

[ 0 to 60 / 0 / 1 sec/step]

Specifies the idling time in the middle

temperature condition.

1-103-019 ExIdl Temp:PRoll

*ENG

[ 0 to 160 / 110 / 1 deg/step]

Specifies the threshold temperature of

the pressure roller for idling extention

mode.

1104

[Fusing Idling BF]

MT: Middle Thick, PR: Pressure Roller

1-104-001 Envir. Thresh

*ENG

[0 to 2 / 2 / 1 /step]

Selects the environmental

condition.

0: LL condition

1: LL and MM condition

2: All condition

1-104-002 Idl Temp:P-Roll

*ENG

[0 to 160 / 160 / 1 deg /step]

Specifies the threshold temperature for the pressure roller idling before a job.

1-104-003 Idling Time:BW

*ENG

Specifies the fusing idling time for

each printe mode before a job.

[0 to 10 / 2 / 1 sec/step]

1-104-004 Idling Time:FC

*ENG

1-104-005 Idl Time:MTh:BW

*ENG

1-104-006 Idl Time:MTh:FC

*ENG

007-009 Specifies the thereshold temperature of the paper feed before a job.

1-104-007 P.FeedTemp:P-Roll

*ENG

[0 to 160 / 90 / 1 deg/step]

1-104-008 P.F Temp:MT:PR:BW

*ENG

[0 to 160 / 100 / 1 deg/step]

1-104-009 P.F Temp:MT:PR:FC

*ENG

[0 to 160 / 100 / 1 deg/step]

5. System Maintenance Reference

274

Summary of Contents for Z-P2

Page 1: ...Model Z P2 Machine Codes M257 Field Service Manual April 2015 ...

Page 2: ......

Page 30: ...1 Product Information 28 ...

Page 73: ...9 Install the securing holder E 10 Reassemble the machine Tray Heater 71 ...

Page 86: ...3 Preventive Maintenance 84 ...

Page 92: ...5 Left cover B Right Cover 1 Open the duplex unit A 4 Replacement and Adjustment 90 ...

Page 128: ...5 Open the upper cover A 4 Replacement and Adjustment 126 ...

Page 131: ...4 The left stay A x 4 5 Rear holder bracket A x 2 Image Transfer 129 ...

Page 139: ...3 Remove the two screws 4 ID sensor board bracket A x 1 Image Transfer 137 ...

Page 141: ...4 Exit the SP mode Image Transfer 139 ...

Page 146: ...2 Temperature Humidity sensor A x 1 x 1 4 Replacement and Adjustment 144 ...

Page 187: ...3 Bracket A x 1 4 Release the paper feed unit A x 1 Paper Feed 185 ...

Page 201: ...5 Inner left upper cover page 94 6 Paper exit unit holder A x 1 Paper Exit 199 ...

Page 211: ...6 Release the left arm A x 1 Duplex Unit 209 ...

Page 215: ...3 Duplex lower guide plate A 4 Duplex upper guide plate A x 7 Duplex Unit 213 ...

Page 220: ...8 Right and left arms A x 2 each 4 Replacement and Adjustment 218 ...

Page 221: ...9 Duplex By pass motor bracket with the frame A x 6 10 Guide plate A x 4 Duplex Unit 219 ...

Page 245: ...5 Disconnect the connector 6 Disconnect the six connectors x 1 Electrical Components 243 ...

Page 254: ...4 Replacement and Adjustment 252 ...

Page 564: ...5 System Maintenance Reference 562 ...

Page 637: ...Model Z P2 Machine Codes M257 Appendices February 2015 ...

Page 638: ......

Page 640: ...2 ...

Page 648: ...1 Appendix Specifications 10 ...

Page 652: ...MEMO 14 ...

Page 653: ...MEMO 15 ...

Page 654: ...MEMO 16 EN ...