Engine, clutch and transmission 2»51

29.3 Carefully lift the crankshaft out of the

crankcase

crankcase half, taking care not to dislodge the

main bearing shells (see illustration).

4 The main bearing shells can be removed

from the crankcase halves by pushing their

centres to the side, then lifting them out (see

illustration). Keep the shells in order.

Inspection

5 Clean the crankshaft with solvent, using a rifle-

cleaning brush to scrub out the oil passages. If

available, blow the crank dry with compressed

air, and also blow through the oil passages.

Check the drive gears for wear or damage (see

illustration). If any of the gear teeth are

excessively worn, chipped or broken, the

crankshaft must be renewed. If wear or damage

is found, check the driven gears on the balancer

shafts, oil pumps, water pump and clutch

housing.

6 Refer to Section 27 and examine the main

bearing shells. If they are scored, badly scuffed

or appear to have been seized, new bearings

must be installed. Always renew the main

bearings as a set. If they are badly damaged,

check the corresponding crankshaft journals.

Evidence of extreme heat, such as discoloration,

indicates that lubrication failure has occurred. Be

sure to thoroughly check the oil pump and

pressure relief valve as well as all oil holes and

passages before reassembling the engine.

7 Give the crankshaft journals a close visual

examination, paying particular attention where

damaged bearings have been discovered. If the

journals are scored or pitted in any way a new

crankshaft will be required. Note that undersizes

are not available, precluding the option of re-

grinding the crankshaft.

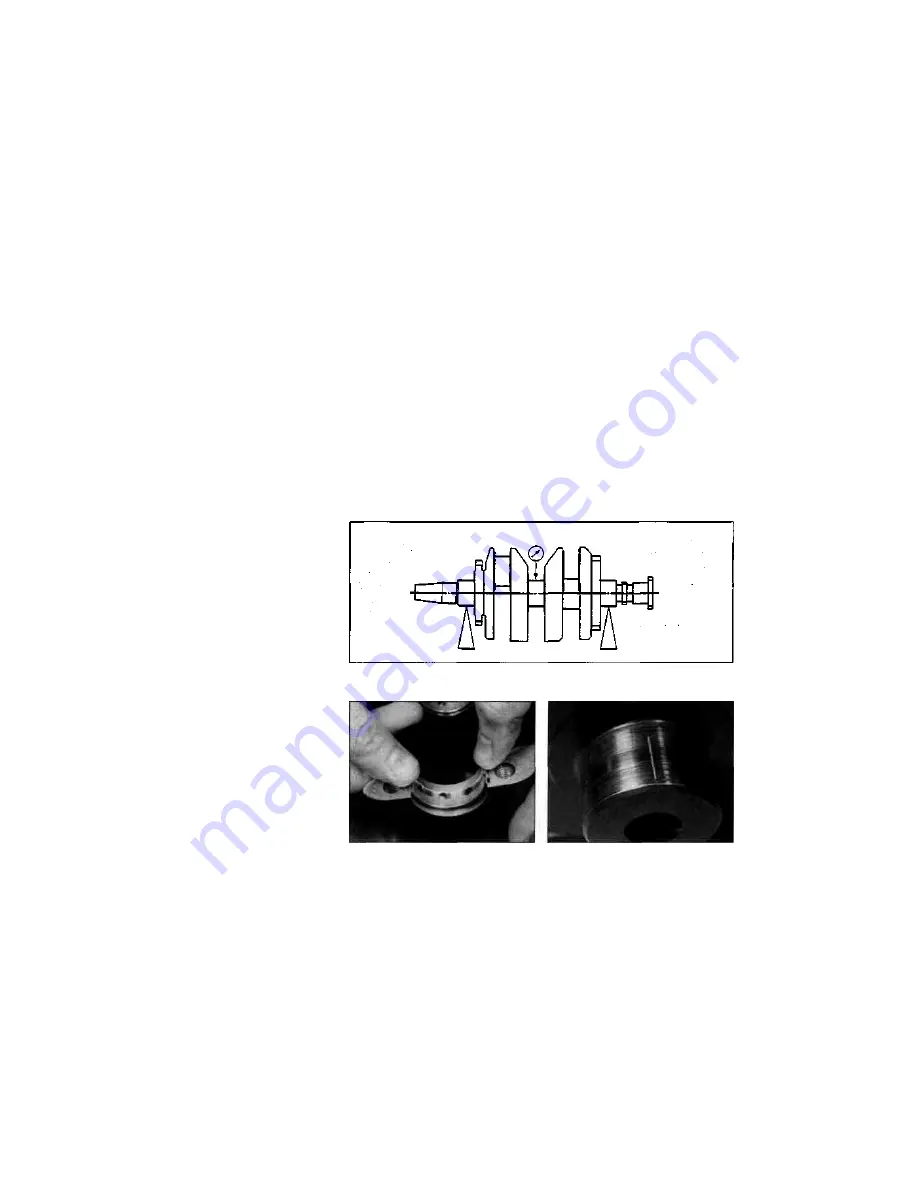

8 Place the crankshaft on V-blocks and check

the runout at the main bearing journals using a

dial gauge (see illustration). Compare the reading

to the maximum specified at the beginning of the

Chapter. If the runout exceeds the limit, the

crankshaft must be renewed.

Oil clearance check

9 Whether new bearing shells are being fitted

or the original ones are being re-used, the

main bearing oil clearance should be checked

before the engine is reassembled. Main

29.4 To remove a main bearing shell, push it

sideways and lift it out

bearing oil clearance is measured with a product

known as Plastigauge.

10 Clean the backs of the bearing shells and

the bearing housings in both crankcase halves.

11 Press the bearing shells into their cutouts,

ensuring that the tab on each shell engages in

the notch in the crankcase (see illustration).

Make sure the bearings are fitted in the correct

locations and take care not to touch any shell's

bearing surface with your fingers.

12 Ensure the shells and crankshaft are clean

and dry. Lay the crankshaft in position in the

upper crankcase.

13 Cut several lengths of the appropriate size

Plastigauge (they should be slightly shorter than

the width of the crankshaft journals).

2

Scaned by

Stalker

29.5 Check the condition of the gear and

sprocket teeth

Place a strand of Plastigauge on each (cleaned)

journal (see illustration). Make sure the

crankshaft is not rotated.

14 If removed, install the locating dowel in the

upper crankcase half (see illustration 25.8).

Carefully install the lower crankcase half on to

the upper half, making sure the dowel locates

correctly into the lower crankcase half (see

illustration 25.15). Check that the lower

crankcase half is correctly seated.

Note:

Do not

tighten the crankcase bolts if the casing is not

correctly seated.

15 Clean the threads of the 10 mm lower

crankcase

bolts

and

apply

molybdenum

disulphide oil (a 50/50 mixture of molybdenum

disulphide grease and new engine oil) to their

threads. Insert them with their washers in their

original locations. Clean the threads of the

29.8 Measuring crankshaft runout

29.13 Lay a strip of Plastigauge on each journal

parallel to the crankshaft centreline

29.11 Make

sure the tab on the shell locates

in the notch in the rod

Содержание XTZ750

Страница 174: ...UNREGISTERED VI ScanedbyStalker UNREGISTERED VI ...

Страница 207: ...Wiring diagrams 9 29 _____Scaned by Stalker 5 l 6o Cxj fi I JICM ...

Страница 208: ...UNREGISTERED VI 9 30 Wiring diagrams UNREGISTERED VERSION 01 ONREGISTEREDVI Scaned by Stalker ONREGISTERED VERSION 0 ...

Страница 209: ...I UNREGISTERED VI Wiring diagrams 9 31 ____ Scaned by Stalker UNREGISTERED VERSION OF PICTURE DESK ...

Страница 210: ...9 32 Wiring diagrams Scaned by Stalker ...

Страница 211: ...XTZ750 gauge Starter circuit Neutral Starter cut off relay switch rnotor ...