For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

99/273

(3)

Tighten the lock nut with the standard tightening

torque using the spanner (#19).

Note:

Mark on the position 100mm of the spanner and press the marked

section vertically using the push-pull gauge until the value reaches

"

63N

"

. Turning it with the hexagon wrench is also available.

(4) Tighten the setscrew with the hexagon wrench (#2).

When the setscrew is to be fixed, apply Screw

Lock 1401B and tighten it with 147cN.m.

(5) Tighten the lock nut with the standard tightening

torque using the spanner (#17).

After tightening the lock nut, fix the lock nut

using the setscrew.

Note:

Mark on the position 100mm of the spanner and press the marked section using the push-pull gauge

until the value reaches

"

28N

"

. Turning it with the hexagon wrench is also available.

After applying Screw Lock 1401B, tighten the lock nut with 147cN.m.

(6)

Fix the ball screw movable section onto the head plate temporarily.

Note: Arrange it so that the ball screw movable section can move slightly.

(7) Slide the head to the motor side (in the direction

①

), and tighten the two upper bolts

slightly.

Note: Tighten it to the extent that the ball screw movable section cannot be moved.

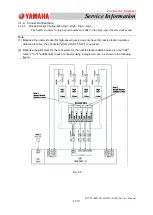

The purpose is to perform the positioning around the center of the ball screw. (Refer to

Fig. C28).

Fig. C28

(8)

Slide the head onto the center of the beam and tighten the two lower bolts lightly.

①

Fix the ball screw movable section

onto head plate temporarily.

Move the head plate in the direction

①

to

center the ball screw.

Fig. C26

Fig. C27

Lock nut

Set screw

Rock Nut

Set screw